Euphausia superba powder with enriched lipid and preparing method thereof

A technology of Antarctic krill powder and krill powder, applied in food heat treatment, food science, food drying, etc., can solve the problems of long heating process, loss of lipid and protein, waste of resources and energy, etc., to improve content and quality, Prevent oxidative degradation, reduce the effect of oxidative degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

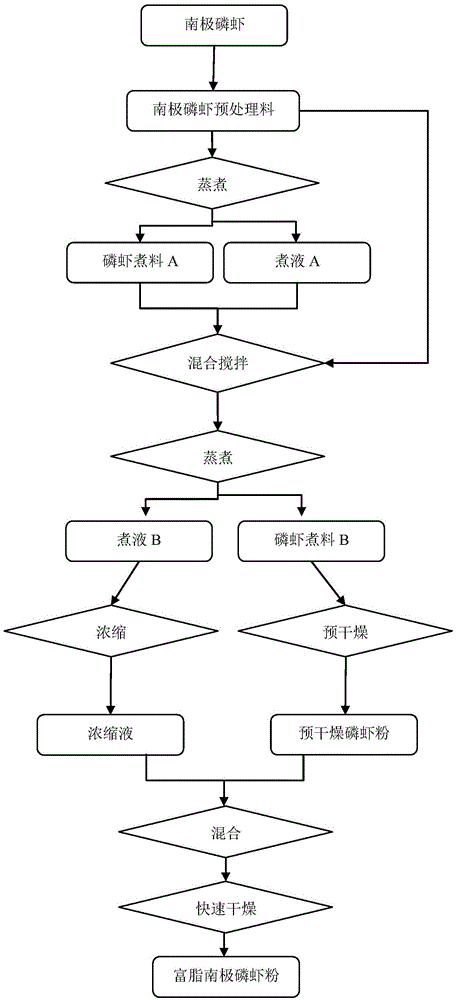

[0035] A kind of processing method of Antarctic krill powder enriched in lipids,

[0036] In the first step, the frozen Antarctic krill powder is thawed by a microwave thawing machine. After thawing, the temperature of the Antarctic krill is about 5°C, and the thawed Antarctic krill is harvested with a 40-mesh meat harvester;

[0037] In the second step, the Antarctic krill meat is heated to 90° C. within 2 minutes to obtain krill cooking material A and cooking liquid A;

[0038] In the third step, the krill cooking material A and the cooking liquid A are stirred and mixed with the uncooked Antarctic krill meat according to the mass ratio of 5:1 to obtain the mixed krill material, and the mixing temperature is kept at 45° C., and stirred for 60 minutes;

[0039] The fourth step is to continue heating the mixed krill feed to 90°C within 2 minutes to obtain krill cooking material B and cooking liquid B;

[0040] The fifth step is to separate the krill cooking material B from th...

Embodiment 2

[0049] Take 10kg of frozen Antarctic krill and thaw it with microwave. After thawing, the overall temperature is 4°C and the mass is 9.6kg. The final mass is 9.5kg; take 7.6kg krill meat and heat it to 90°C; then mix 7.6kg krill meat and cooking liquid with 1.9kg krill meat, the temperature after mixing is 55°C, and stir the mixed material with a mixer for 60min ; After heating the mixed krill feed to 90°C, centrifuge it with a centrifuge at 4500×g; take out the obtained precipitate, put it into an oven for drying, and dry it until the moisture content is 50%, so as to obtain pre-dried Antarctic krill powder; Concentrate the obtained supernatant in a rotary evaporator under reduced pressure until the solid content reaches 20% to obtain a concentrated solution; the dried Antarctic krill powder and the concentrated solution are mixed, and then dried by an airflow dryer. The drying time is The drying time was 5min, and the final moisture content was 10.4%. The dried shrimp powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com