Graphene dispersant and applications thereof

A graphene dispersant and graphene technology, applied in the field of graphene dispersants, can solve the problems of graphene material chemical composition and physical morphology changes, insignificant effect, non-universal application, etc., to facilitate large-scale implementation, The effect of low cost and improved dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

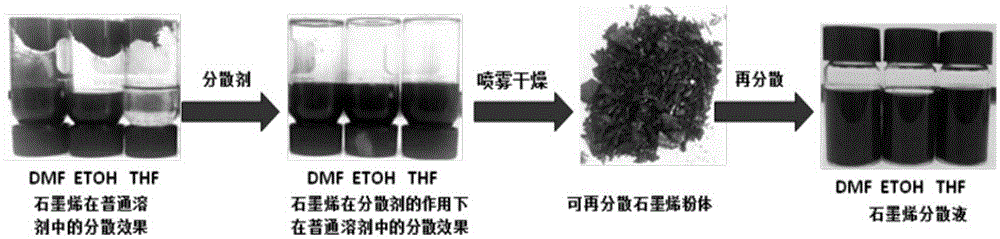

[0061] Another aspect of the present invention also provides a method for preparing a graphene dispersion, which includes: uniformly mixing graphene and the graphene dispersant in a dispersion medium to form a stable dispersion.

[0062] In some embodiments, a graphene dispersion method may include: only dissolving the graphene dispersant and graphene in an organic solvent, thereby forming a stable dispersion. It should be noted that the "dissolved" mentioned here is not understood by those of ordinary skill as dissolved, but should be understood as "incorporated", "dispersed into" or "mixed in", etc. For example, the graphene dispersant and graphene can be added into an organic solvent, and stirred or ultrasonically dispersed, for example, ultrasonically dispersed for more than 1 hour, so as to form a stable dispersion liquid.

[0063] More preferably, the dispersion contains graphene at a concentration of 1 mg / ml-10 mg / ml.

[0064] In the graphene dispersion method, the mol...

Embodiment 1

[0081] Synthesis of embodiment 1 aniline trimer carboxyl derivative and graphene aqueous dispersion thereof

[0082] Dissolve 1.24 g of aniline trimer in 50 ml of THF, add 1.04 g of succinic anhydride, react for 3 hours, and precipitate with petroleum ether to obtain aniline trimer carboxyl derivatives. Weigh the obtained aniline trimer carboxyl derivatives and 2 times the molar equivalent of NaOH and configure different concentrations of aqueous solutions with the graphene slurry (graphene content 4.5%), and ultrasonically disperse for 1 hour. The effect is shown in Table 1. At the graphene concentration When it is below 3mg / ml, a stable dispersion can be formed.

[0083] Table 1 Aqueous dispersion of aniline trimer carboxyl derivative-graphene

[0084] 5mg / 10ml

[0085] good

Embodiment 2

[0086] Example 2 Synthesis of aniline tetramer carboxyl derivatives and graphene aqueous dispersion thereof

[0087] Add 2.0 g of aniline tetramer into 50 ml of THF, and add 0.67 g of succinic anhydride, react at 40° C. for 3 hours, and precipitate with petroleum ether to obtain aniline tetramer carboxyl derivatives. The obtained aniline tetramer carboxyl derivatives and 2 times the molar equivalent of NaOH and graphene are configured into an aqueous solution of a certain concentration, and ultrasonicated for half an hour, the dispersion effect is shown in Table 2. When the concentration of graphene is below 2.5mg / ml Able to form a homogeneous dispersion.

[0088] Table 2 Aniline tetramer carboxyl derivatives-graphene aqueous dispersion effect

[0089] 5mg / 10ml

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com