Automatic production line for AG anti-dazzle panel display glass

A flat panel display glass and automatic production line technology, which is applied in the field of AG anti-glare flat panel display glass automatic production line, can solve the problems of inability to prepare target products with optical performance requirements of AG glass, inability to realize refined management and control of etching process, and lack of process adjustment Work area and other problems, to achieve the effect of improving the efficiency of thinning and polishing, reducing the amount of thinning and polishing, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

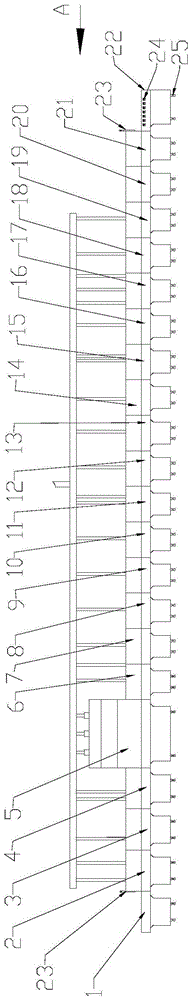

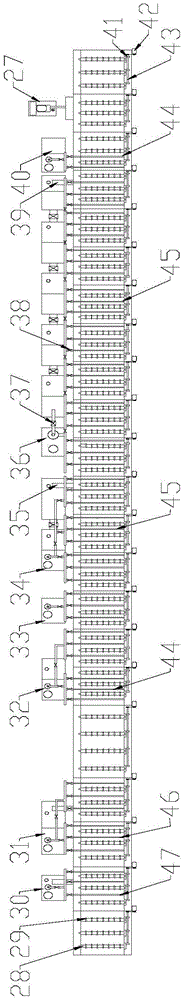

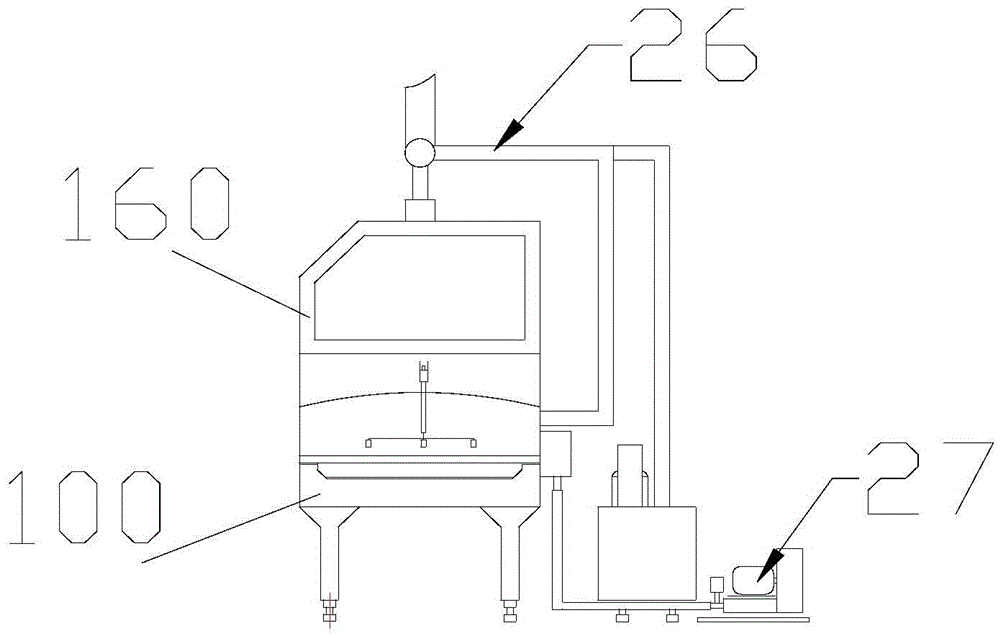

[0061] see Figure 1~6 , the automatic production line of AG anti-glare flat panel display glass described in this embodiment is provided with the following work area: the work area is in turn a feeding area 1, a pickling area 2, a first etching area 3, and a second etching area 4 , turnover area 5, first to third washing areas 6 to 8, first to eleventh thinning and polishing areas 9 to 19, washing and drying area 20, air drying area 21 and discharge area 22, and DCS control system (not shown). Each station area can be detachably connected in series, and each station area is tightly connected by fasteners. Each station area is provided with a rack and an independent transmission system, and the racks of each station area are connected in series to form an overall rack 100 . Adjustable legs 25 are provided at the bottom of the frame of each station area. Such as Figure 4~6 As shown, the transmission system of each station area is provided with a transmission motor 42, a ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com