A long-life gasoline engine oil with multiple anti-wear protection and its preparation method

A gasoline engine oil, long-life technology, applied in the field of lubricating oil, can solve the problems of easy precipitation, loss of anti-wear effect, poor oil solubility of boron substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

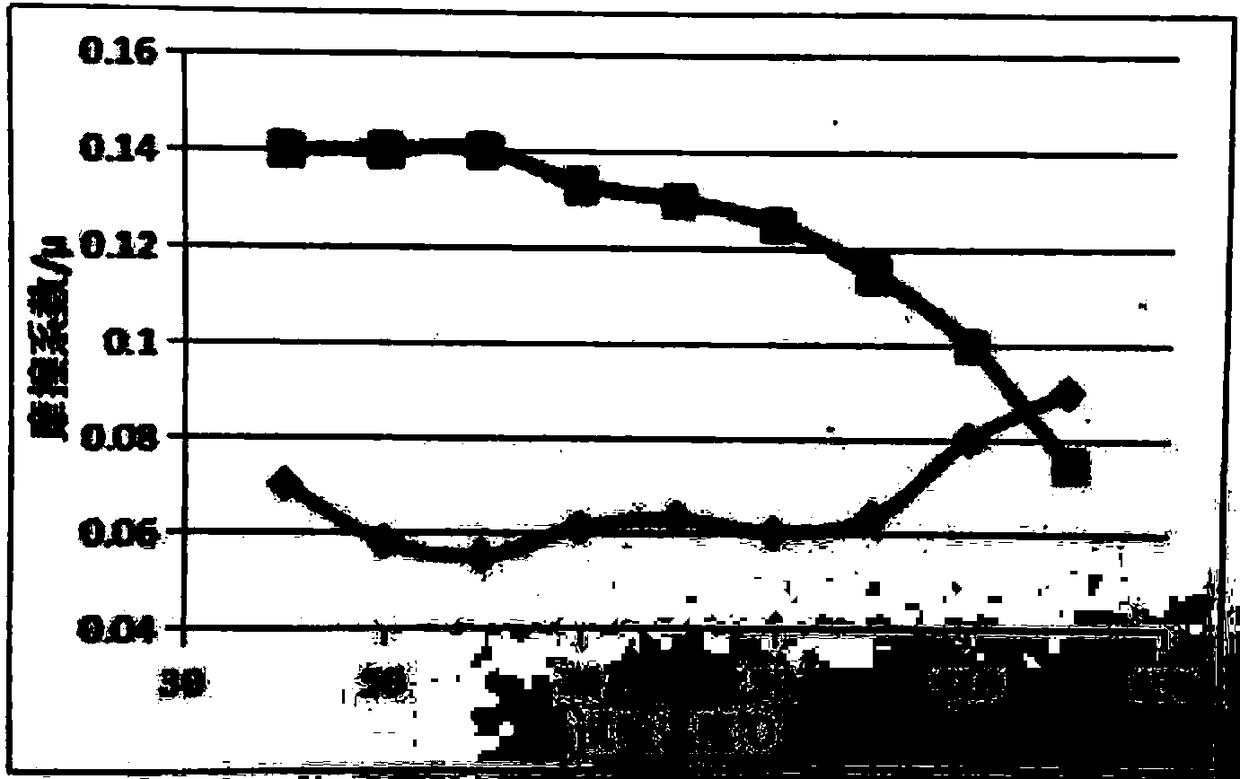

Image

Examples

Embodiment 1

[0069] The base oil is obtained by uniformly mixing 20 parts of PAO 4, 15 parts of PAO 8, 20 parts of di(2-ethylhexyl) azelate, 10 parts of polyester and 15 parts of GTL-4 base oil.

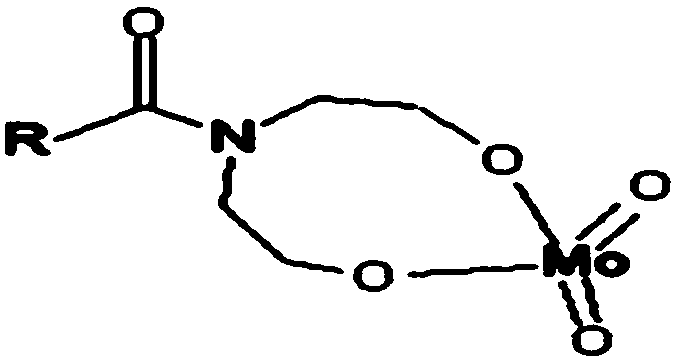

[0070] Long-life multiple anti-wear protection gasoline engine oil raw materials: long-life multiple anti-wear protection gasoline engine oil raw materials (mass percentage): Afton H111008%, hydrogenated styrene isoprene copolymer 2.5%, ethylene-propylene copolymer 2.5%, antioxidant 0.42%, anticorrosion agent (the brand that Guangzhou Zhengtong Chemical Co., Ltd. provides is the anticorrosion agent of T203) 0.3%, polymethacrylate 0.3%, molybdenum dialkyl dithiocarbamate ( Vanderbilt M822) 0.3%, molybdenum amine complex (Vanderbilt M855) 0.3%, simethicone 0.003%, and the balance is base oil.

[0071] The antioxidant consists of 2,2-methylidene bis(6-cyclohexyl-4-methylphenol), 2,4-bis(dodecylthiomethyl)-6-methylphenol, 4, 4'-Dioctyldiphenylamine is mixed in a mass ratio of 1:1:1.

[0072] Prepar...

Embodiment 2

[0075] The base oil is obtained by uniformly mixing 20 parts of PAO 4, 15 parts of PAO 8, 20 parts of di(2-ethylhexyl) azelate, 10 parts of polyester and 15 parts of GTL-4 base oil.

[0076] Long-life multiple anti-wear protection gasoline engine oil raw materials: long-life multiple anti-wear protection gasoline engine oil raw materials (mass percentage): Afton H111008%, hydrogenated styrene isoprene copolymer 2.5%, ethylene-propylene copolymer 2.5%, antioxidant 0.42%, anticorrosion agent (the brand of anticorrosion agent T203 provided by Guangzhou Zhengtong Chemical Co., Ltd.) 0.3%, polymethacrylate 0.3%, molybdenum amine complex (Vanderbilt The company's M855) 0.3%, simethicone 0.003%, and the balance is base oil.

[0077] The antioxidant consists of 2,2-methylidene bis(6-cyclohexyl-4-methylphenol), 2,4-bis(dodecylthiomethyl)-6-methylphenol, 4, 4'-Dioctyldiphenylamine is mixed in a mass ratio of 1:1:1.

[0078] Preparation of long-life gasoline engine oil with multiple an...

Embodiment 3

[0081] The base oil is obtained by uniformly mixing 20 parts of PAO 4, 15 parts of PAO 8, 20 parts of di(2-ethylhexyl) azelate, 10 parts of polyester and 15 parts of GTL-4 base oil.

[0082] Long-life multiple anti-wear protection gasoline engine oil raw materials: long-life multiple anti-wear protection gasoline engine oil raw materials (mass percentage): Afton H111008%, hydrogenated styrene isoprene copolymer 2.5%, ethylene-propylene copolymer 2.5%, antioxidant 0.42%, anticorrosion agent (the brand that Guangzhou Zhengtong Chemical Co., Ltd. provides is the anticorrosion agent of T203) 0.3%, polymethacrylate 0.3%, molybdenum dialkyl dithiocarbamate ( Vanderbilt's M822) 0.3%, simethicone 0.003%, and the balance is base oil.

[0083] The antioxidant consists of 2,2-methylidene bis(6-cyclohexyl-4-methylphenol), 2,4-bis(dodecylthiomethyl)-6-methylphenol, 4, 4'-Dioctyldiphenylamine is mixed in a mass ratio of 1:1:1.

[0084] Preparation of long-life gasoline engine oil with mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com