Method for evaluating influence of drilling and completion fluid on oil and water permeability of rock core

A technology of oil-water penetration and evaluation method, applied in the direction of permeability/surface area analysis, suspension and porous material analysis, measuring device, etc., to achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

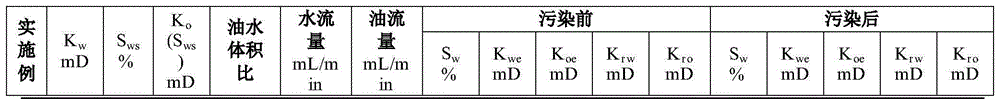

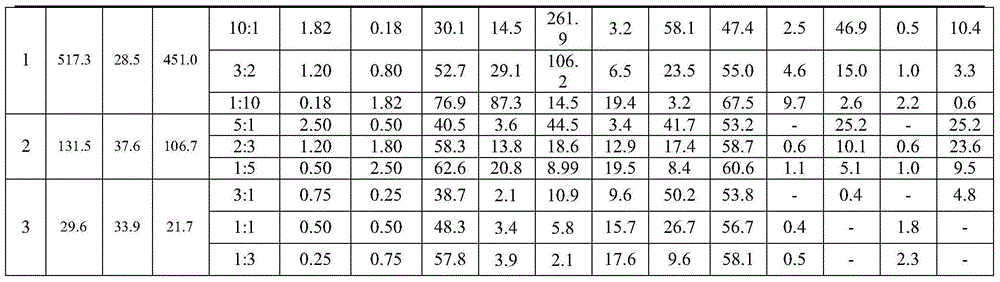

example 1

[0029] Evaluation of experimental slurry (formula: 6% sodium bentonite slurry + 0.2% sodium hydroxide + 0.2% polyacrylamide PAM + 1.0% LV-CMC + 3% SMP-2 + 3% polymer alcohol + 1.5% anti-high temperature dehydration agent HX-KYG + 2% nanoemulsion + 2% oil-soluble resin) reservoir protection effect, the experimental core selects the artificial sandstone core with gas phase permeability of 1385.20 mD, the porosity is 27.32%, and the size is: length 6.21cm, 2.53cm in diameter.

[0030] (1) Preparation of core and experimental fluid:

[0031]Dry the core to be tested and weigh the dry weight. The experimental temperature is 25°C. The total salinity of the simulated formation water is 1000mg / L, and the viscosity at 25°C is Simulated oil is prepared from crude oil and kerosene, with a density of 0.84g / cm 3 , the viscosity at 25°C is The oil-water viscosity ratio is 3.5:1; the core is vacuumed and saturated with simulated formation water, weighed wet, and the effective pore volum...

example 2

[0039] Evaluation of experimental slurry (formula: 5% sodium bentonite slurry + 0.3% IND30 + 3% SMP-2 + 3% nanoemulsion + 0.5% amino polyalcohol + 0.4% aluminum-based polymer + 2% hydrophobically modified starch HNC-1 +1.5% nano-calcium carbonate) for reservoir protection effect, the experimental core was selected from Shengli Qingdong 8 Well Sha3 Member core, taken from a depth of 1212.10-1214.15 meters, with a porosity of 26.15%, a gas phase permeability of 399.78 mD, and a size of It is: length 6.23cm, diameter 2.53cm.

[0040] (1) Preparation of core and experimental fluid:

[0041] The core to be tested was dried and weighed dry, and the experimental temperature was selected according to the geological conditions of the Qingdong 8 well reservoir, and the experimental fluid-simulated formation water and simulated oil were prepared; among them, the experimental temperature was selected at 46°C, and the total salinity of the simulated formation water was It is 4755mg / L, the...

example 3

[0049] Evaluation of on-site slurry (formula: 5-8% sodium bentonite slurry + 0.2% - 0.3% sodium hydroxide + 0.3% - 0.5% natural polymer coating inhibitor IND30 + 1.0% - 1.5% anti-high temperature fluid loss reducer HX- KYG+2%~3% Polymer alcohol+1%~2% natural polymer fluid loss reducer NAT20+3%~5% ideal filler+2%~3% waterproof locking agent YFS-3) Reservoir protection effect , The experimental core was selected from Shengli Chengbei 326 Well Dongying Formation core, taken from a depth of 3489.00 to 3502.00 meters, with a porosity of 17.87%, a gas phase permeability of 93.90 mD, and a size of 6.26 cm in length and 2.53 cm in diameter.

[0050] (1) Preparation of core and experimental fluid:

[0051] The core to be tested was dried and weighed dry, and the experimental temperature was selected according to the geological conditions of Chengbei 326 well reservoir, and the experimental fluid-simulated formation water and simulated oil were prepared; among them, the experimental tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com