Low temperature polysilicon thin film transistor and its manufacturing method

A technology of thin-film transistors and low-temperature polysilicon, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of abnormal electrical properties of TFT devices, unsatisfactory activation and hydrogenation effects, etc., so as to improve utilization rate and hydrogenation effect, the effect of increasing the activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] This embodiment provides a low-temperature polysilicon thin film transistor, and its fabrication method is as follows:

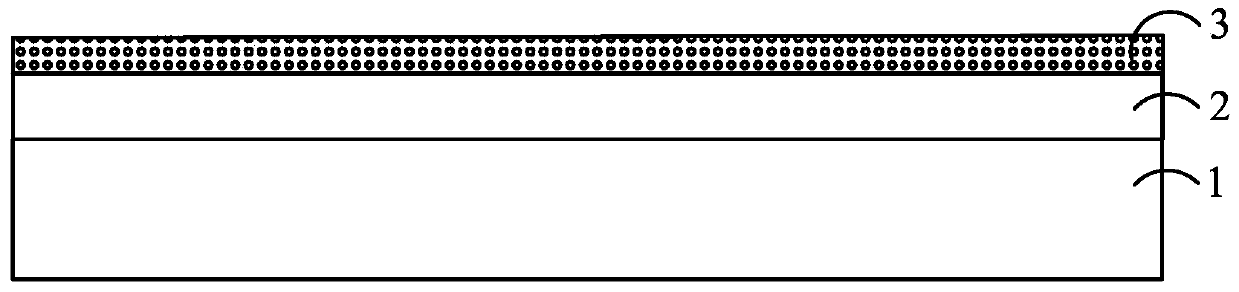

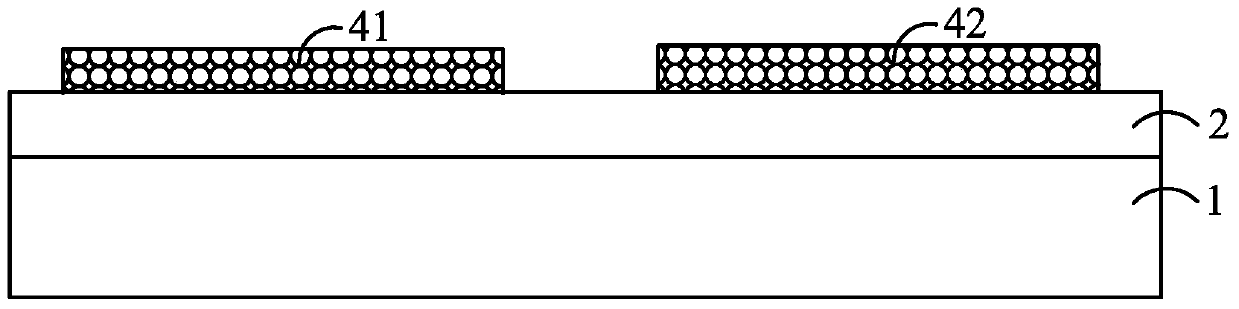

[0031] Such as figure 2 As shown, a glass substrate 1 is provided, and a buffer layer 2 and an amorphous silicon layer 31 are sequentially deposited on the glass substrate 1 by chemical vapor deposition (CVD, Chemical Vapor Deposition), wherein the buffer layer is a silicon nitride layer. Using excimer laser annealing (ELA, Excimer Laser Annel) or solid phase crystallization (SPC, Solid Phase Crystallization) method to transform the amorphous silicon layer 3 into a polysilicon layer, and then define the polysilicon layer by photolithography and etching processes such as image 3 In the two polysilicon island patterns shown, the two polysilicon islands are the active layers, the one on the left is the first active layer 41 , and the one on the right is the second active layer 42 .

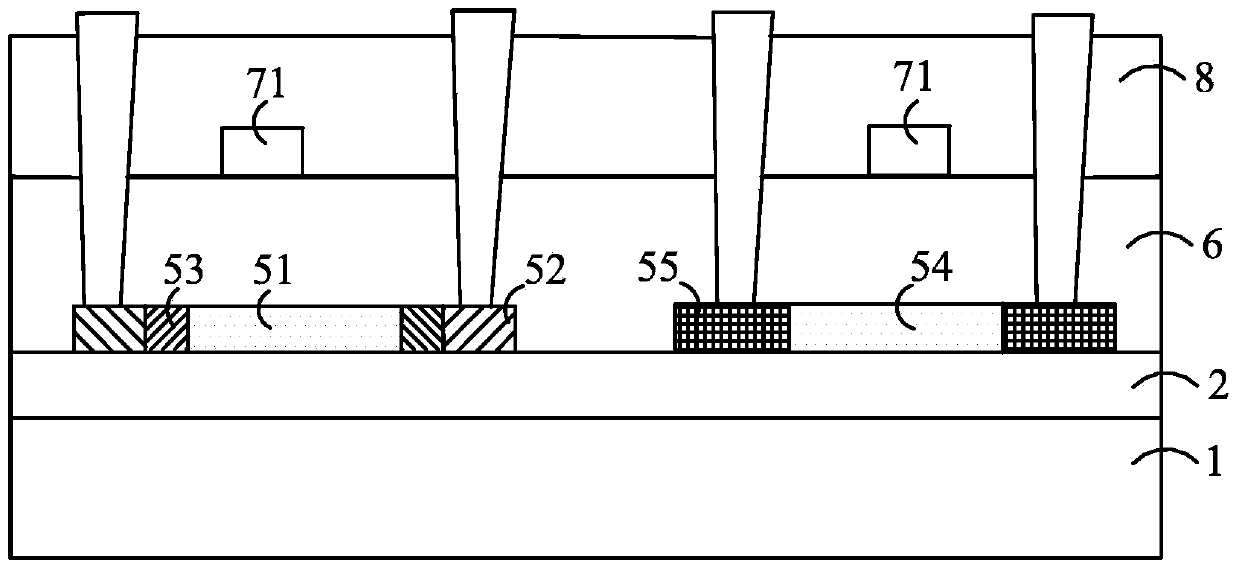

[0032] Next, if Figure 4 As shown, the first channel 51 , the N+ r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com