High-platinum base-loaded carbon nano tube nanocatalyst and preparation method thereof

A carbon nanotube, multi-walled carbon nanotube technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the anti-poisoning ability of catalytic oxidation of carbon monoxide is not significantly improved, and platinum nanoparticles are stable. It can improve the anti-poisoning ability, reduce the cost of catalyst and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

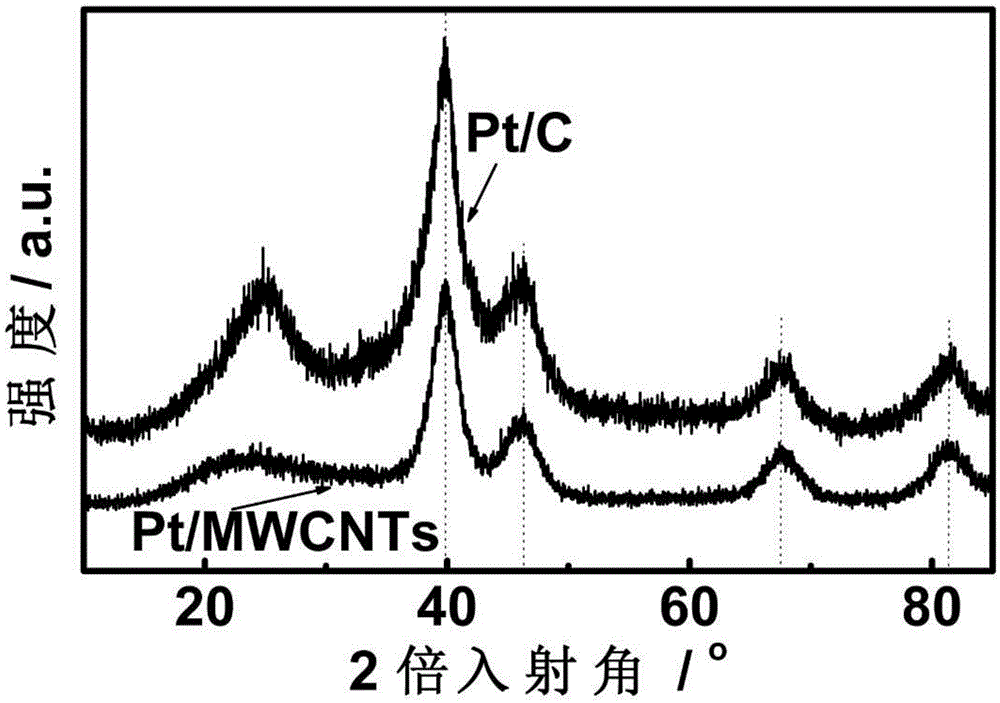

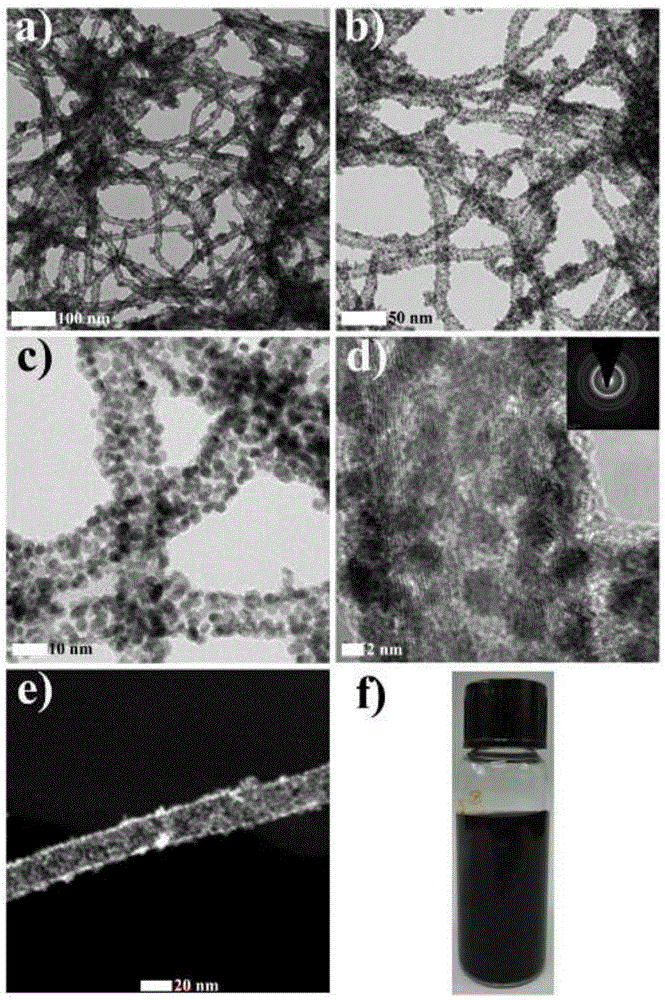

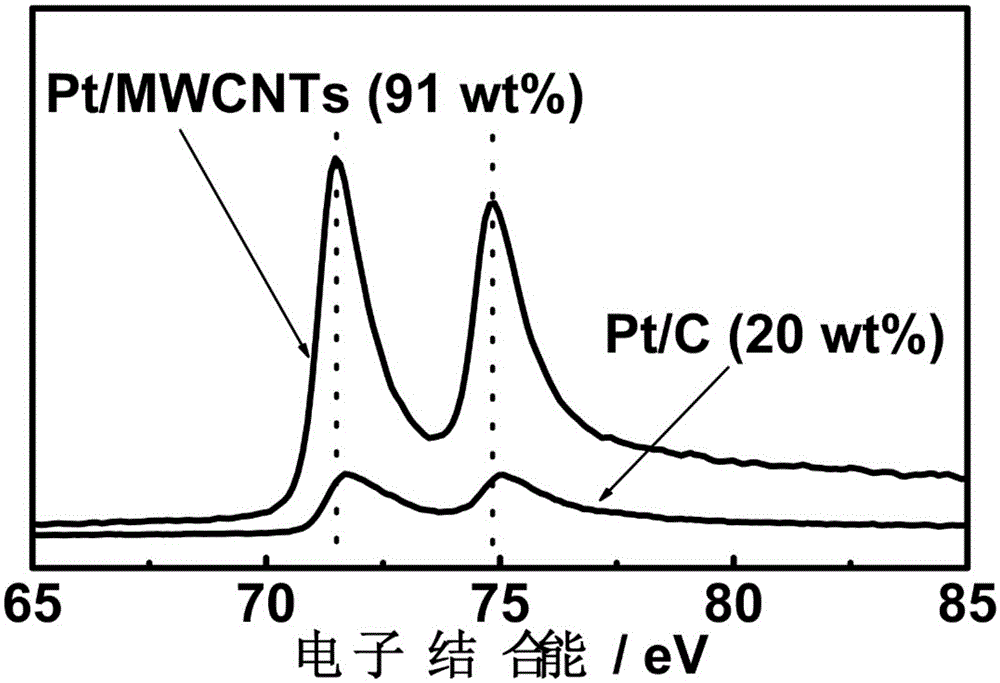

[0045] Embodiment 1: the preparation of multi-walled carbon nanotube loaded high load platinum nanocatalyst Pt / MWCNTs (the weight percent of platinum in platinum and multi-walled carbon nanotube is 91%)

[0046] (1) Disperse multi-walled carbon nanotubes (MWCNTs) in toluene, add azobisisobutyronitrile, pass through nitrogen, react in an oil bath at 75 degrees Celsius for more than 4 hours, cool and filter, and then disperse in sodium hydroxide The aqueous solution was stirred in an oil bath at 70 degrees Celsius for more than 48 hours. Finally, the reaction solution is filtered and washed, dried and ground to obtain carboxylated multi-walled carbon nanotubes for subsequent use;

[0047] (2) H 2 PtCl 6 ·6H 2 O, the carboxylated multi-walled carbon nanotubes and ethylene glycol in step (1) were stirred at room temperature for more than 30 minutes to fully disperse them, and continued to sonicate. By alternately using agitation and ultrasound, a highly dispersed solution-like...

Embodiment 2

[0060] Example 2: Multi-walled carbon nanotubes loaded with high-load platinum-copper catalyst PtCu 3 Preparation of / MWCNTs (the weight percentage of platinum in platinum, copper and multi-walled carbon nanotubes exceeds 90%)

[0061] (1) H 2 PtCl 6 ·6H 2 O, CuSO 4 ·5H 2 O, carboxylated multi-walled carbon nanotubes and ethylene glycol were stirred at room temperature for 30 minutes to fully disperse them. The molar ratio of Pt and Cu in the mixed solution is 1:3. At the same time, metal Pt accounts for more than 90% of the weight of carbon, Cu and Pt;

[0062] (2) the mixed solution obtained in step (1) is alternately used to stir and sonicate, and then adjust its pH value to 10 with sodium hydroxide ethylene glycol solution;

[0063] (3) Continue to alternately use ultrasound and stirring the mixed solution obtained in step (2) until a solution-like dispersion is formed;

[0064] (4) Put the mixed solution obtained in step (3) into a microwave reactor, ventilate nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com