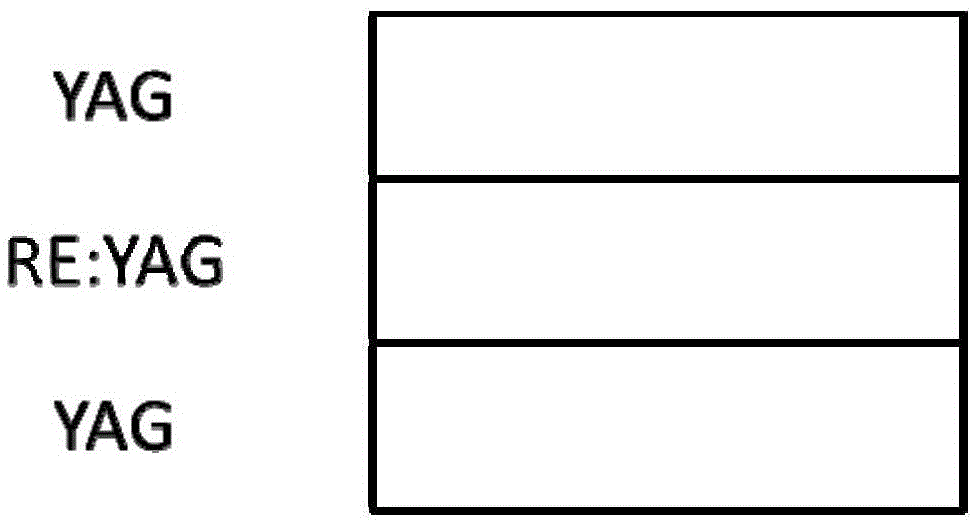

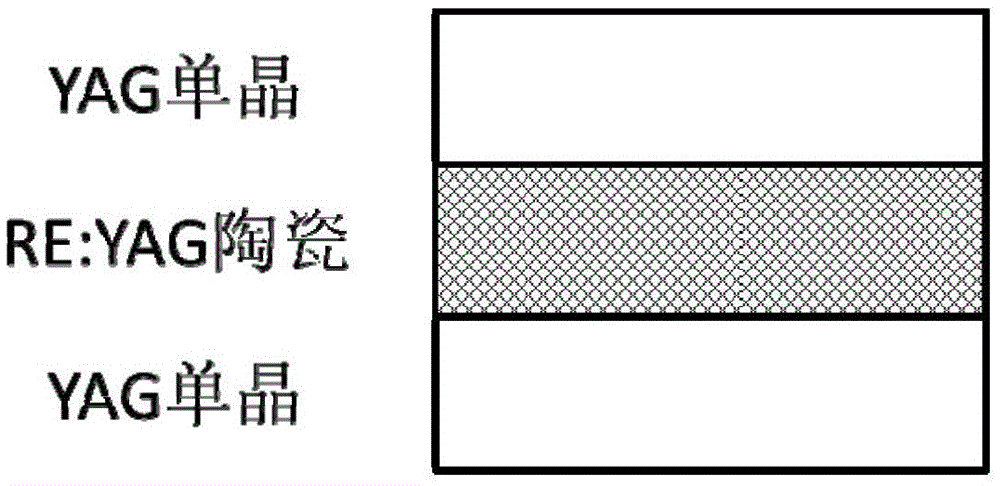

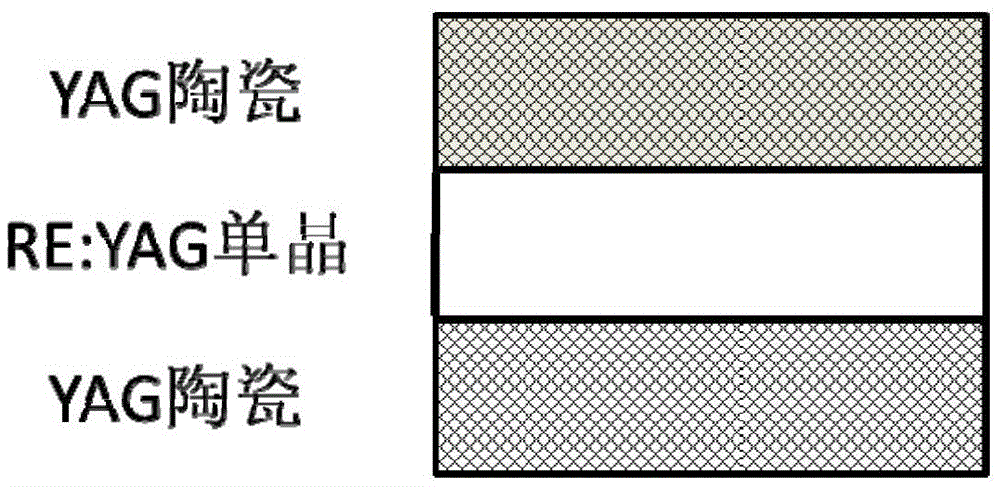

Rare earth ion doped yttrium aluminum garnet laser material with sandwich ceramic and single-crystal composite structure and preparation method thereof

A technology of yttrium aluminum garnet and rare earth ions is applied in the field of sandwich ceramic single crystal composite structure laser material and its preparation, which can solve the problems of thermal prism effect, damage to laser gain medium, restrict the application of high-power laser devices, etc., and achieve good gain Effects of increased output, increased laser pumping intensity, and improved thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Cut a piece of Yb:YAG ceramic with x=0.03 into a 30mm*20mm*1mm cuboid, and cut two YAG single crystals into a 30mm*20mm*10mm cuboid. Polish the upper and lower surfaces of all the cuboids according to YAG|Yb:YAG In the order of |YAG, three cuboids are stacked in the thickness direction, and the two adjacent sides are glued. Put the glossy sandwich composite structure into the vacuum sintering furnace, and vacuum to 9*10 -3 Pa, incubated at 1800°C for 20h to obtain the final sample.

[0023] The rest of the implementation parameters are shown in the following table:

[0024]

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com