Micro-capsule-coated compound plant essential oil feed additive and preparation method thereof

A technology for feed additives and plant essential oils, applied in the field of feed additives, can solve the problems of volatile, unstable plant essential oils, difficult to pass through the stomach and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

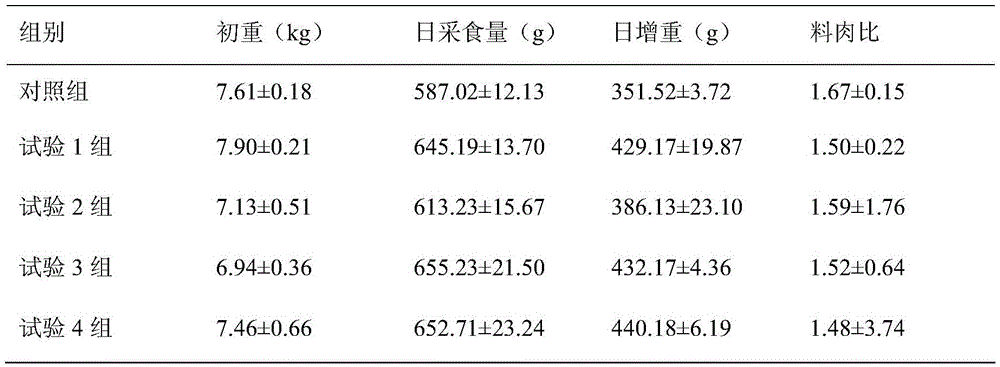

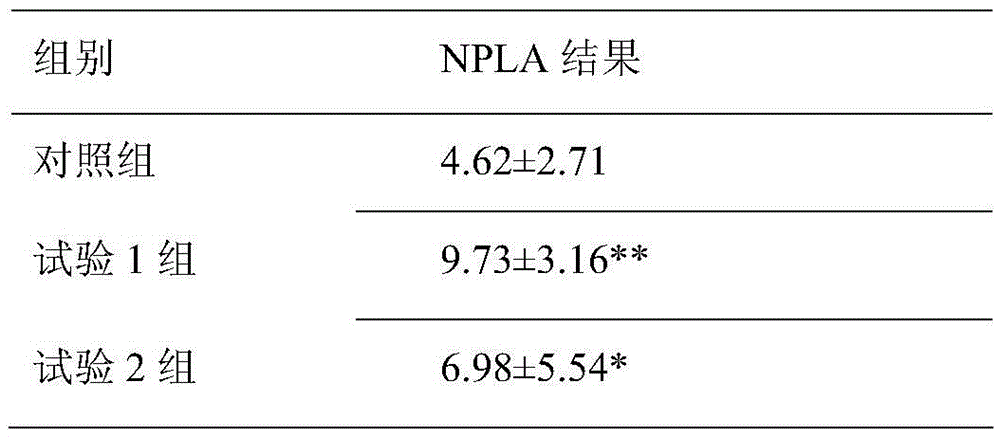

Examples

Embodiment 1

[0015] Embodiment 1: Prepare the finished product of the composite plant essential oil feed additive of microcapsule coating

[0016] Ingredients: eugenol 500g, thymol 700g, carvacrol 400g, cinnamaldehyde 1500g, ginger essential oil 800g, capsicum essential oil 500g, 50g BHT (2,6-di-tert-butyl-4-methylphenol), auxiliary materials 3kg , and the balance is water.

[0017] Preparation steps:

[0018] (1) Take each raw material according to the corresponding weight for subsequent use;

[0019] (2) Add 1.5kg each of the auxiliary materials gelatin and white sugar to the same amount of hot water (the temperature that can dissolve gelatin)

[0020] After mixing, add the above-mentioned essential oil raw materials one by one. The selected gelatin has a power rating of 150. 50 g of BHT (2,6-di-tert-butyl-4-methylphenol) were added. Viscosity is measured with a viscometer, preferably controlled at about 15mPa·S, and the emulsification temperature is kept at about 60 degrees;

[00...

Embodiment 2

[0029] Embodiment 2: Prepare the finished product of the composite plant essential oil feed additive of microcapsule coating

[0030] Ingredients: eugenol 700g, thymol 1000g, carvacrol 600g, cinnamaldehyde 2000g, ginger essential oil 700g, capsicum essential oil 400g, 20g BHT (2,6-di-tert-butyl-4-methylphenol), auxiliary material 2kg , and the balance is water.

[0031] Preparation steps:

[0032] (1) Take each raw material according to the corresponding weight for subsequent use;

[0033] (2) Add 1kg each of auxiliary materials gelatin and white granulated sugar, add an equal amount of hot water (temperature capable of dissolving gelatin) and mix well, and then add the above-mentioned essential oil raw materials one by one. The selected gelatin has a power rating of 150. 20 g of BHT (2,6-di-tert-butyl-4-methylphenol) were added. Viscosity is measured with a viscometer, preferably controlled at about 15mPa·S, and the emulsification temperature is kept at about 50 degrees; ...

Embodiment 3

[0037] Embodiment 3: the compound plant essential oil feed additive finished product of preparation microcapsule coating

[0038] Ingredients: eugenol 400g, thymol 500g, carvacrol 200g, cinnamaldehyde 900g, ginger essential oil 600g, capsicum essential oil 500g, 20g BHT (2,6-di-tert-butyl-4-methylphenol), accessories 4kg , and the balance is water.

[0039] Preparation steps:

[0040] (1) Take each raw material according to the corresponding weight for subsequent use;

[0041] (2) Add 2.0kg each of the auxiliary materials gelatin and white sugar, add an equal amount of hot water (at a temperature capable of dissolving gelatin) and mix well, and then add the above-mentioned essential oil raw materials one by one. The selected gelatin has a power rating of 150. 20 g of BHT (2,6-di-tert-butyl-4-methylphenol) were added. Viscosity is measured with a viscometer, preferably controlled at about 20mPa·S, and the emulsification temperature is kept at about 70 degrees;

[0042] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com