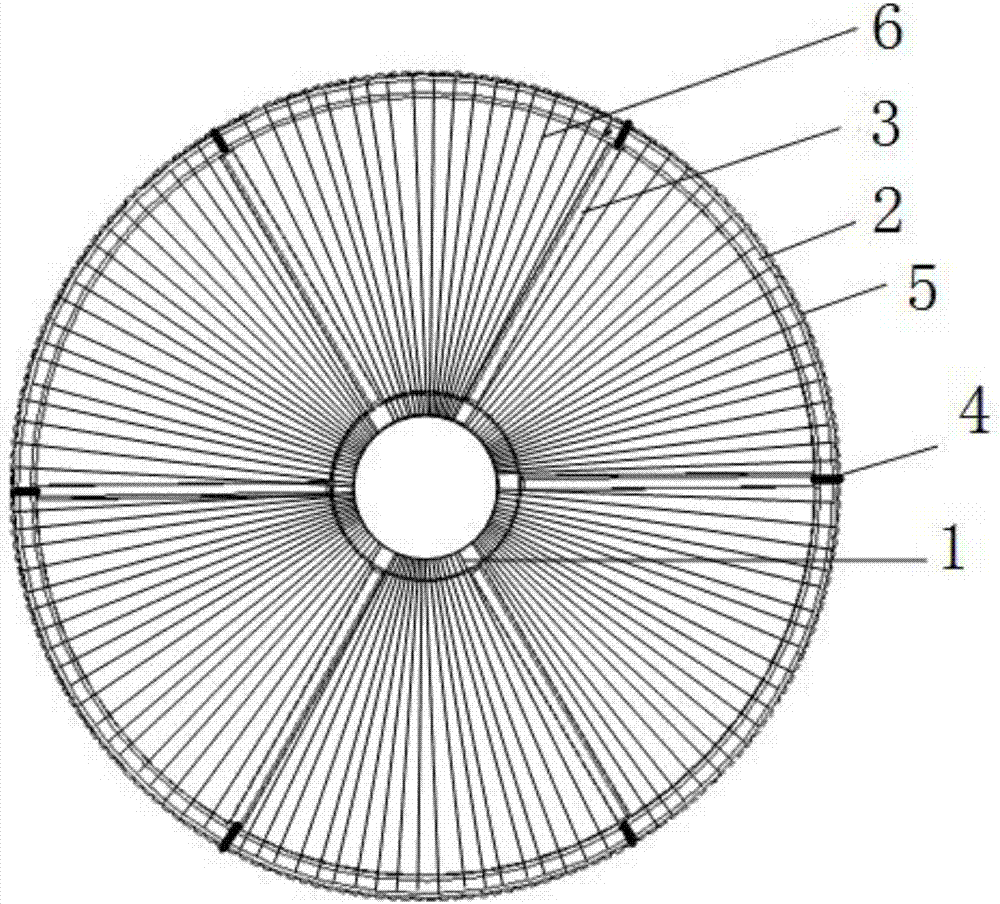

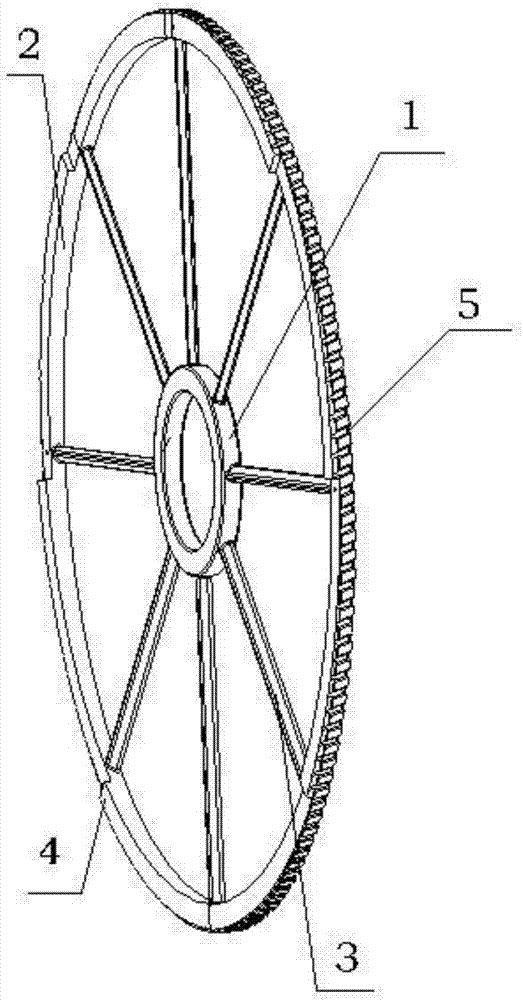

Double Disc Fume Filter

A technology of oil fume filter and disc filter, which is applied in the direction of membrane filter, dispersed particle filtration, chemical instruments and methods, etc., can solve the problem of pollutants entering, reduce pollution, improve the extraction rate and filter effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

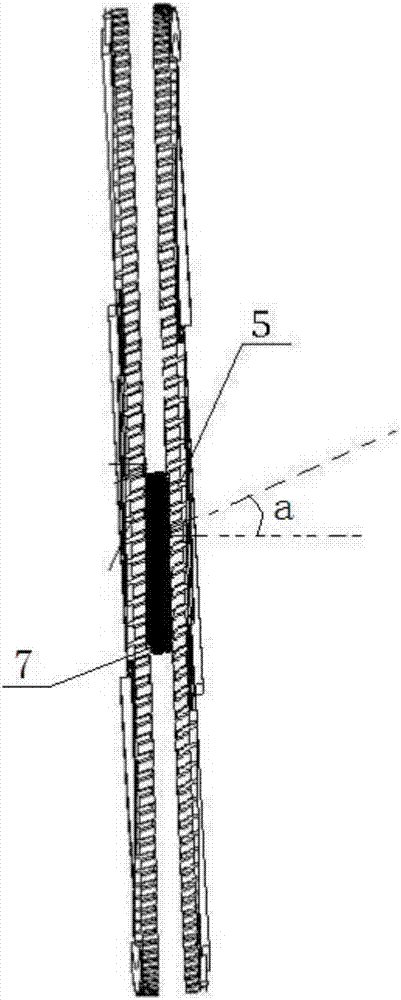

Image

Examples

Embodiment 1

[0033] (1) Mix 15 parts of polyether ether ketone resin, 12 parts of polybutene, 30 parts of vulcanized rubber, 6 parts of maleic anhydride grafted polyolefin, and 13 parts of methacrylic acid, and stir at 250 ° C; quickly cool down to 100°C, and add 7 parts of side chain amino silicone oil polymer coupling agent, 13 parts of alicyclic petroleum resin and 5 parts of tribasic lead sulfate, stir for 1 minute, heat up to 220°C again, and add 11 parts of polyether Ether ketone, stirring to obtain a polymer;

[0034] (2) Polymer is pelletized by twin-screw extruder to obtain polyester masterbatch;

[0035] The obtained polyester masterbatch and polyethylene are mixed according to the ratio of 1:5, and then the high-strength and high-toughness polyethylene fiber is obtained through the process of melt spinning and high-power drafting. The process of melt spinning and high-strength drawing is as follows: the spinning temperature is 220°C, the spinning speed is 4m / min, the draw ratio...

Embodiment 2

[0037] (1) Mix 20 parts of polyetheretherketone resin, 15 parts of polybutene, 35 parts of vulcanized rubber, 8 parts of maleic anhydride grafted polyolefin, and 16 parts of methacrylic acid, and stir at 278 ° C; quickly cool down to 110°C, and add 9 parts of side chain amino silicone oil polymer coupling agent, 15 parts of alicyclic petroleum resin and 7 parts of tribasic lead sulfate, stir for 1 minute, heat up to 220°C again, and add 14 parts of polyether Ether ketone, stirring to obtain a polymer;

[0038] (2) Polymer is pelletized by twin-screw extruder to obtain polyester masterbatch;

[0039] The obtained polyester masterbatch and polyethylene are mixed according to the ratio of 1:6, and then the high-strength and high-toughness polyethylene fiber is obtained through the process of melt spinning and high-strength drafting. The process of melt spinning and high-strength drawing is as follows: the spinning temperature is 220°C, the spinning speed is 4m / min, the draw rati...

Embodiment 3

[0041](1) 10 parts of polyether ether ketone resin, 10 parts of polybutene, 25 parts of vulcanized rubber, 4 parts of maleic anhydride grafted polyolefin, 10 parts of methacrylic acid, mixed, and stirred at 220°C; Cool to 100°C, add 5 parts of side chain amino silicone oil polymer coupling agent, 11 parts of alicyclic petroleum resin and 3 parts of tribasic lead sulfate, stir for 1 minute, heat up to 200-220°C again, and add 9 parts of polyether ether ketone, stirring to obtain a polymer;

[0042] (2) granulating the polymer through a twin-screw extruder to obtain a polyester master batch;

[0043] After mixing the obtained polyester masterbatch and polyethylene in a ratio of 1:4, high-strength and high-toughness polyethylene fibers are obtained by melt-spinning-high-drawing process. The melt-spinning and high-drawing processes are as follows: the spinning temperature is 220 °C, the spinning speed is 4 m / min, the drafting ratio is 12 times, and the drafting temperature is 105...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com