Composite turbocharger turbine shaft and its processing and assembling method

A turbocharger, composite technology, applied in other manufacturing equipment/tools, shafts, shafts and bearings, etc., can solve the problem of insufficient guarantee of the connection strength of the turbine shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

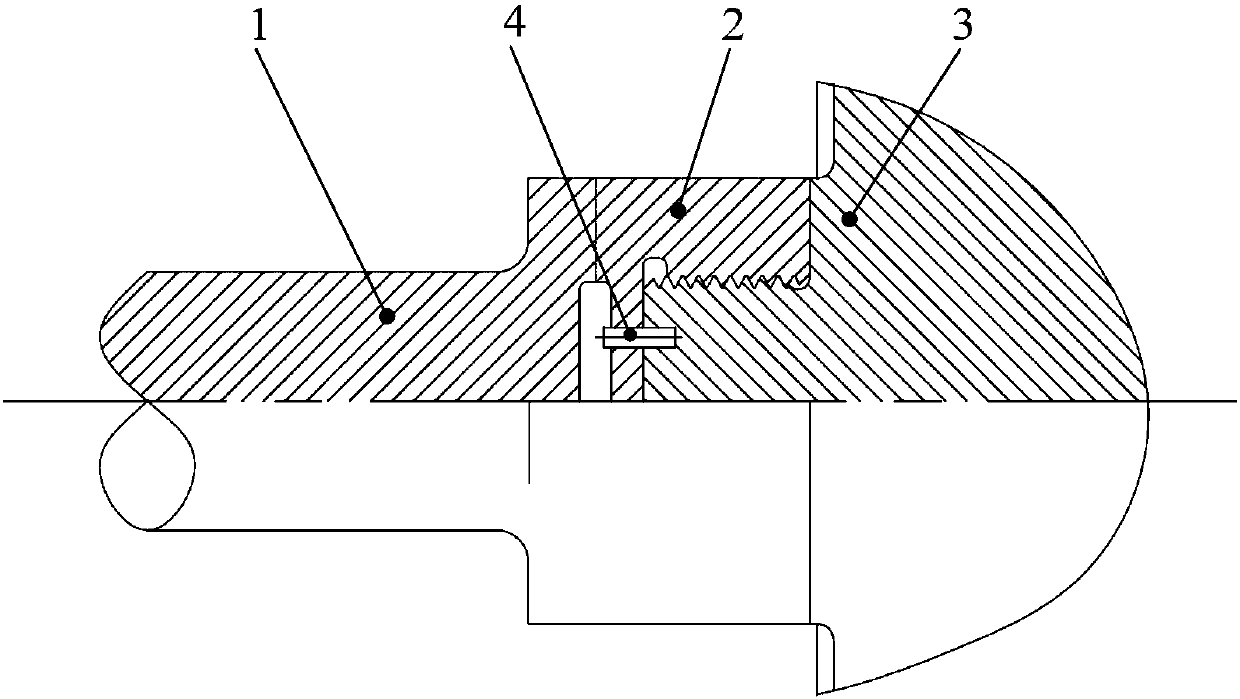

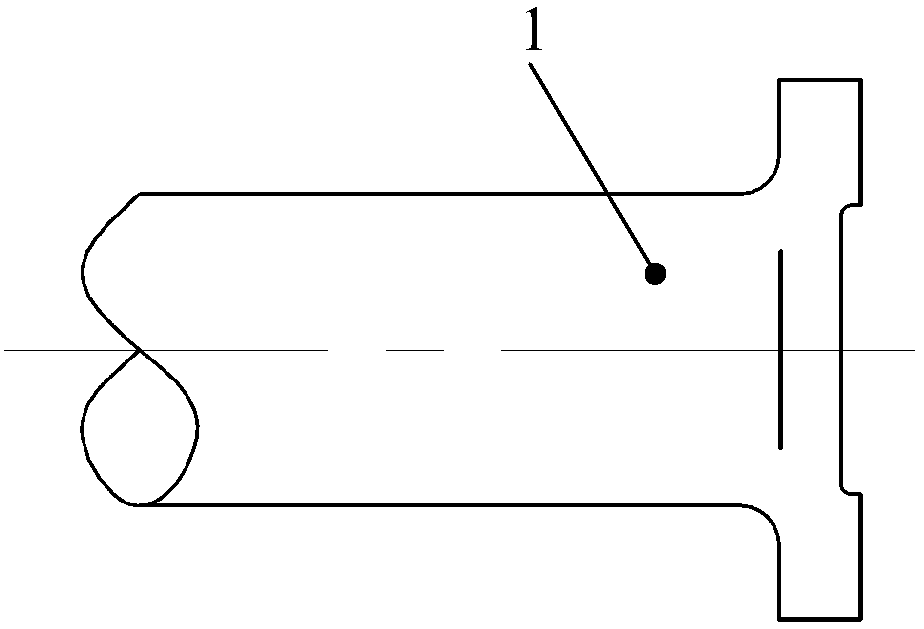

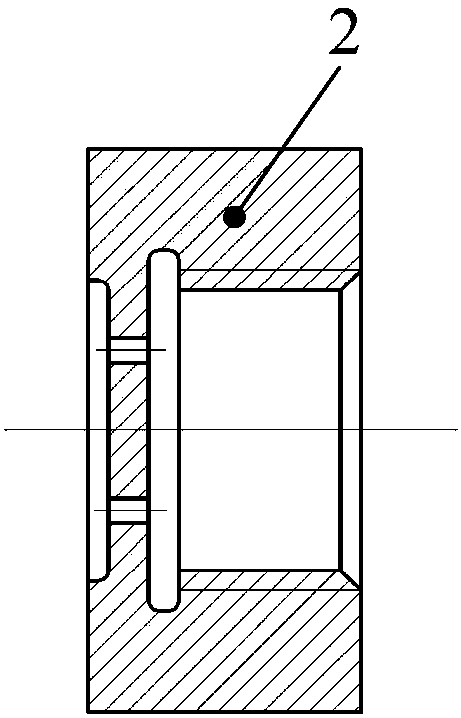

[0029] Compound supercharger turbine shaft structure, such as Figures 1 to 4 As shown, it includes a rotating shaft 1, a transition sleeve 2, a turbine impeller 3 and a pin 4. One end of the rotating shaft 1 has an annular boss welded with the transition sleeve 2; the transition sleeve 2 can be connected to the rotating shaft 1 through a welding process One end of the transition sleeve 2 has an annular boss welded with the rotating shaft 1, the other end of the transition sleeve 2 has a threaded blind hole assembled with the turbine impeller 3, and the bottom of the threaded blind hole of the transition sleeve 2 There are through holes for installing pins 4 evenly distributed along the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com