Preparation method of hexagonal-tube-shaped indium oxide with complex as precursor

A technology of indium oxide and complexes, which is applied in the field of preparation of inorganic oxide semiconductor materials, can solve the problems of large and difficult effective control, and achieve the effects of uniform size, simple and easy process, and novel product appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

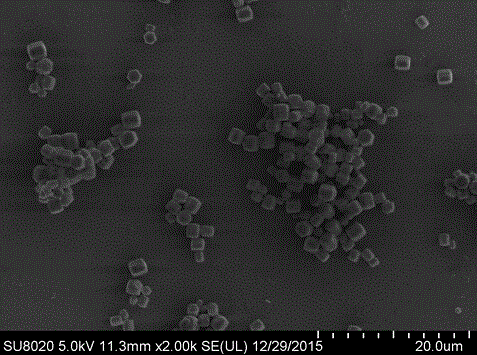

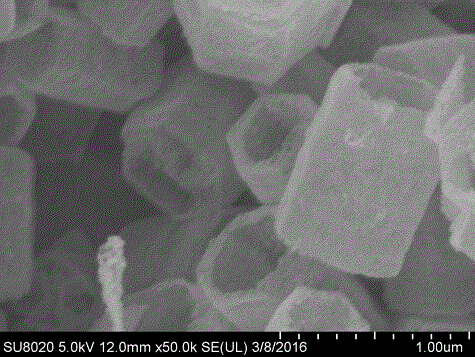

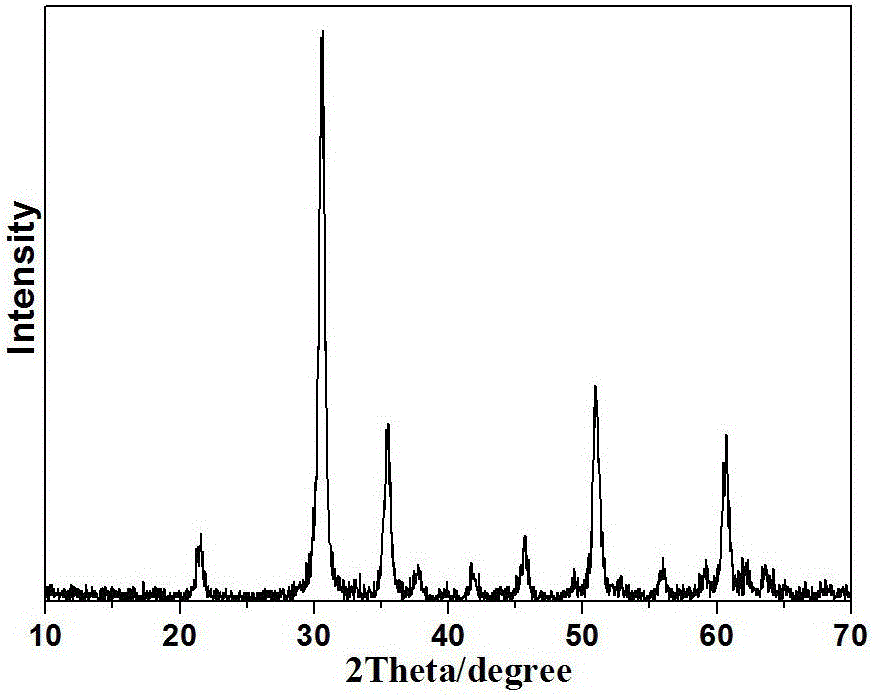

[0025] Firstly, indium nitrate pentahydrate was weighed and dissolved in DMF to prepare 10 ml of a solution with a concentration of 0.05 moles per liter. Then terephthalic acid was weighed and dissolved in DMF to prepare 10 ml of a solution with a concentration of 0.05 moles per liter. Then the above two solutions were mixed and mixed at 50 o C under stirring for 20 minutes to obtain a milky white cloudy liquid. After the above turbid solution was centrifuged at 3000 rpm for 10 minutes, the colorless solution in the centrifuge tube was removed to obtain a milky white precipitated product, which was indium(III)-terephthalic acid complex. Successively use DMF and deionized water to ultrasonically clean the precipitated product three times and o Tumble dry at C. The dried complex was transferred to a crucible and placed in a muffle furnace. with 1 o C / min heating rate from room temperature to 500 o C and keep warm for 50 minutes, and naturally cool down to room temperature ...

Embodiment 2

[0027] Firstly, indium nitrate pentahydrate was weighed and dissolved in DMF to prepare 10 ml of a solution with a concentration of 0.1 moles per liter. Then terephthalic acid was weighed and dissolved in DMF to prepare 10 ml of a solution with a concentration of 0.1 moles per liter. Then the above two solutions were mixed and mixed at 50 o C under stirring for 30 minutes to obtain a milky white cloudy solution. After the above turbid solution was centrifuged at 4000 rpm for 15 minutes, the colorless solution in the centrifuge tube was removed to obtain a milky white precipitated product, which was indium(III)-terephthalic acid complex. Successively use DMF and deionized water to ultrasonically clean the precipitated product three times and o Tumble dry at C. The dried complex was transferred to a crucible and placed in a muffle furnace. to 2 o C / min heating rate from room temperature to 400 o C and keep warm for 80 minutes, and naturally cool down to room temperature to...

Embodiment 3

[0029] Firstly, indium nitrate pentahydrate was weighed and dissolved in DMF to prepare 10 ml of a solution with a concentration of 0.2 moles per liter. Then terephthalic acid was weighed and dissolved in DMF to prepare 10 ml of a solution with a concentration of 0.2 moles per liter. Then the above two solutions were mixed and mixed at 50 o C under stirring for 30 minutes to obtain a milky white cloudy solution. After the above turbid solution was centrifuged at 4000 rpm for 15 minutes, the colorless solution in the centrifuge tube was removed to obtain a milky white precipitated product, which was indium(III)-terephthalic acid complex. Successively use DMF and deionized water to ultrasonically clean the precipitated product three times and o Tumble dry at C. The dried complex was transferred to a crucible and placed in a muffle furnace. to 2 o C / min heating rate from room temperature to 500 o C and keep warm for 60 minutes, and naturally cool down to room temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com