Synthetic method of propiophenone compound

A synthesis method and compound technology, which is applied in the field of synthesis of propiophenone compounds, can solve problems such as complex reaction steps, and achieve the effects of reducing reaction costs, simplifying synthesis routes, and simple operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

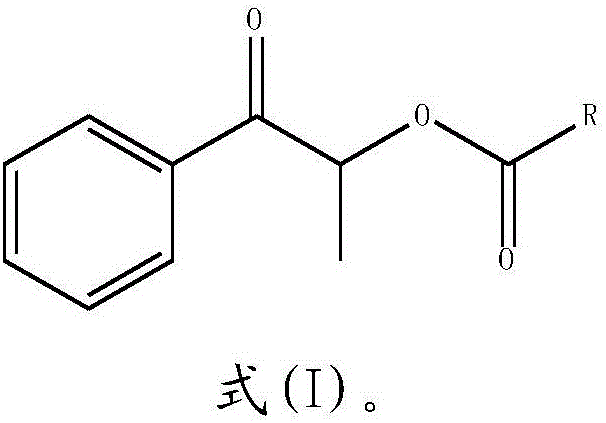

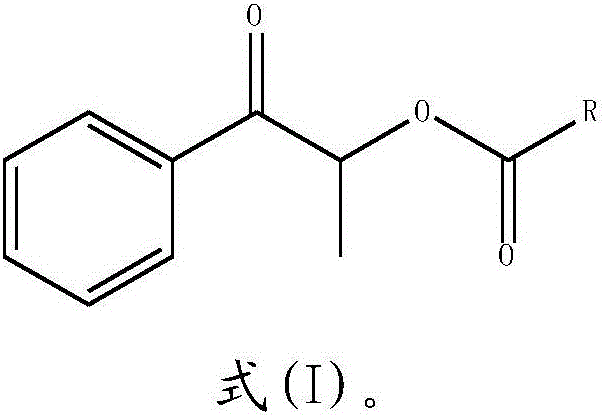

[0018] The embodiment of the present invention provides a synthetic method of propiophenone compounds, comprising:

[0019] S1: Add propylbenzene, organic acid, iodine, and tert-butyl hydroperoxide into the reaction kettle, and react at 80°C-120°C for 8-24 hours.

[0020] In this step, the "one-pot method" can be used to synthesize propiophenone compounds. Specifically, propylbenzene, organic acid, tert-butyl hydroperoxide and iodine are added to the reaction kettle together, and heated at 80°C- React at 120°C for 8-24 hours to produce the target product. The specific reaction process is as follows:

[0021]

[0022] S2: After the reaction is completed, the reaction solution is extracted with an organic solvent, and dried to obtain a propiophenone compound:

[0023]

[0024] The embodiment of the present invention provides a kind of synthetic method of propiophenone compound, compared with prior art, the synthetic method provided by the present invention is to utilize p...

Embodiment 1

[0033] Add propylbenzene, benzoic acid, iodine, and tert-butyl hydroperoxide with a mmol ratio of 1:1:0.2:6 into the reactor, and react at 80°C for 8 hours; after the reaction is completed, use ethyl acetate The reaction solution was extracted with ester and dried to obtain a white solid powder, i.e. Propiophenone Compound A:

[0034]

[0035] Carry out nuclear magnetic spectrum analysis to above-mentioned white solid powder, data is as follows:

[0036] 1 HNMR (CDCl 3 ,400MHz)δ1.69(d,J=6.8Hz,3H),6.23(q,J=6.8Hz,1H),7.45–7.53(m,4H),7.54–7.60(m,2H),8.01–8.03 (m,2H),8.09–8.14(m,2H);

[0037] 13 CNMR (CDCl 3 ,100MHz)δ17.2,71.4,128.5,128.6,128.8,129.5,129.7,133.2,133.5,134.5,165.3,196.8;

[0038] After identification, the spectral data corresponded to the structural formula, proving that the compound A was synthesized, and the yield was 86%.

Embodiment 2

[0040] Add propylbenzene, 4-methylbenzoic acid, iodine, and tert-butyl hydroperoxide with a mmol ratio of 1:2:0.3:8 to the reaction kettle, and react at 120°C for 24 hours; after the reaction is completed , the reaction solution was extracted with ethyl acetate, and dried to obtain a white solid powder, that is, propiophenone compound B:

[0041]

[0042] Carry out nuclear magnetic spectrum analysis to above-mentioned white solid powder, data is as follows:

[0043] 1 HNMR (CDCl 3 ,400MHz)δ1.69(d,J=6.9Hz,3H), 2.43(s,3H), 6.21(q,J=6.9Hz,1H), 7.21–7.25(m,2H), 7.40–7.53(m ,2H), 7.60–7.64(m,1H), 7.90–8.00(m,4H);

[0044] 13 CNMR (CDCl 3 ,100MHz) δ17.2, 21.3, 71.5, 126.7, 128.2, 128.6, 128.9, 129.9, 133.8, 134.4, 143.9, 165.9, 197.0;

[0045] After identification, the spectral data corresponded to the structural formula, proving that the synthesized compound was propiophenone compound B with a yield of 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com