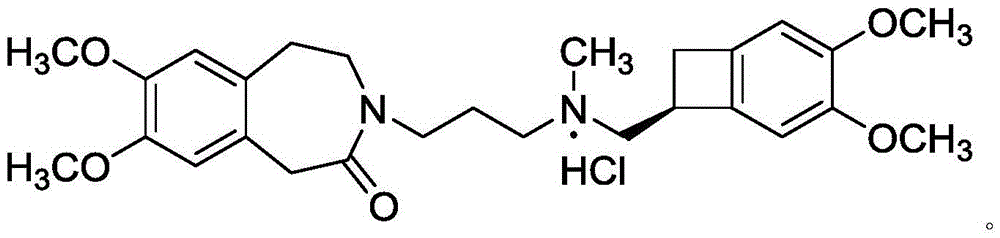

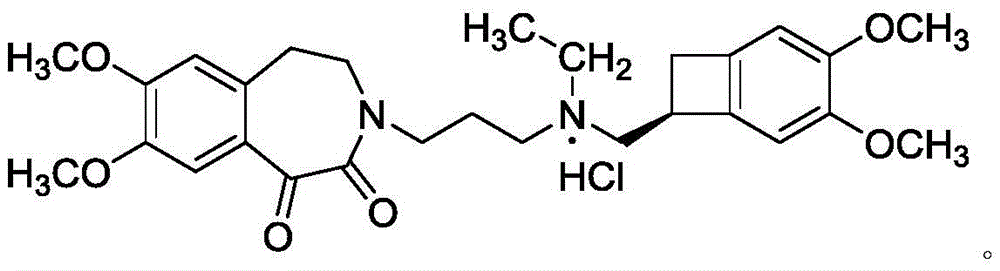

Ivabradine hydrochloride impurity and preparation method and application thereof

An ivabradine hydrochloride and impurity technology is applied in the field of ivabradine hydrochloride impurity and its preparation, which can solve the problems of large content, optimal selection, unknown structure and the like, and achieves simple operation, mild reaction conditions, guaranteed safety and high efficiency. Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

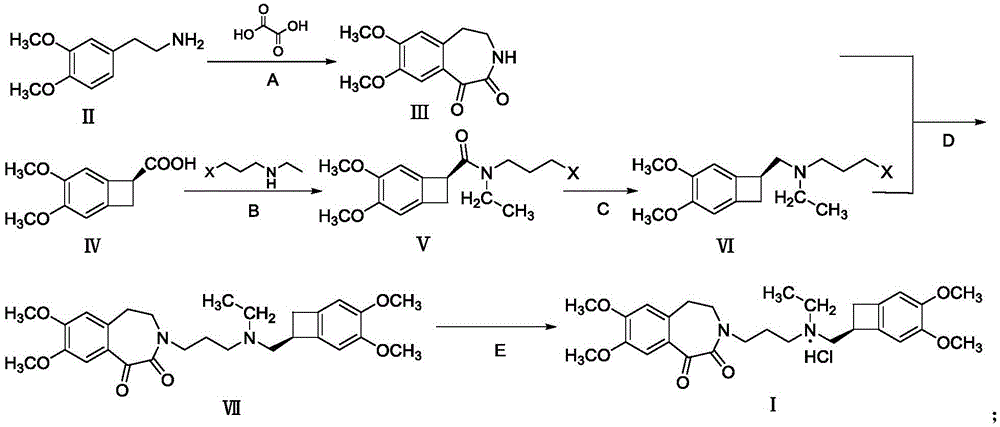

[0030] Embodiment 1: the preparation of intermediate III

[0031] In 500 mL of acetonitrile, 50 g (0.3 mol) of starting material II, 30 g (0.33 mol) of oxalic acid, and 138 g (0.67 mol) of dicyclohexylcarbodiimide were added, and the reaction was stirred for 3 h. After the reaction, filter, evaporate the filtrate to dryness under reduced pressure, and recrystallize the residue with isopropyl acetate to obtain 52 g of off-white solid, namely Intermediate III, with a yield of 75%.

Embodiment 2

[0032] Embodiment 2: the preparation of intermediate III

[0033] In 500 mL of dichloromethane, 50 g (0.3 mol) of starting material II, 30 g (0.33 mol) of oxalic acid, and 138 g (0.67 mol) of dicyclohexylcarbodiimide were added, and the reaction was stirred for 3 h. After the reaction, filter, evaporate the filtrate to dryness under reduced pressure, and recrystallize the residue with isopropyl acetate to obtain 56 g of off-white solid, ie intermediate III, with a yield of 81%.

Embodiment 3

[0034] Embodiment 3: the preparation of intermediate III

[0035] In 500 mL of acetone, add 50 g (0.3 mol) of starting material II, 30 g (0.33 mol) of oxalic acid, and 138 g (0.67 mol) of dicyclohexylcarbodiimide, and stir for 3 hours. After the reaction, filter, evaporate the filtrate to dryness under reduced pressure, and recrystallize the residue with isopropyl acetate to obtain 49 g of off-white solid, namely Intermediate III, with a yield of 71%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com