Industrial preparation method for polypentabrombenzamide acrylate with high purity and high stability

A technology of polypentabromobenzyl acrylate and pentabromobenzyl acrylate, which is applied in the field of industrial preparation of high-purity and high-stability polypentabromobenzyl acrylate, can solve the problem of deep color, low purity and problems of pentabromobenzyl bromide Problems such as deep color to achieve the effect of ensuring chroma and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

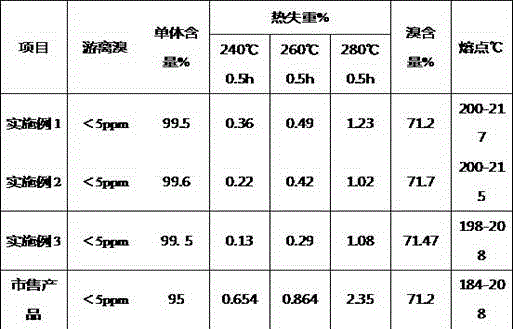

Embodiment 1

[0029] A method for industrialized preparation of high-purity and high-stability polypentabromobenzyl acrylate, comprising the following steps:

[0030] (1) Synthesize light-colored pentabromotoluene by controlling the low-temperature reaction, as follows: put bromine into the reaction kettle, control the reaction temperature at -5°C, control the weight ratio of toluene to bromine to 1:19, and control the toluene at After 6 hours, the dropwise addition was completed, and then the heat preservation reaction was carried out. After the reaction was completed, excess bromine was evaporated, centrifuged, and the material was washed with water until neutral to obtain pentabromotoluene;

[0031] (2) Purify the pentabromotoluene obtained in step (1), as follows: heat pentabromotoluene and solvent to 40°C, stir for 2 hours, then crystallize at 0°C, and centrifuge the product to obtain pure white pentabromotoluene It can reach 99.5%. Among them, dichloroethane is used as solvent, and th...

Embodiment 2

[0037] A method for industrialized preparation of high-purity and high-stability polypentabromobenzyl acrylate, comprising the following steps:

[0038](1) Synthesize light-colored pentabromotoluene by controlling the low-temperature reaction, as follows: put bromine into the reaction kettle, control the reaction temperature at 10°C, control the weight ratio of toluene and bromine to 1:25, and control the toluene at 10h The dropwise addition is completed, and then the heat preservation reaction is carried out. After the reaction is completed, excess bromine is evaporated, centrifuged, and the material is washed to neutrality to obtain pentabromotoluene;

[0039] (2) Purify the pentabromotoluene obtained in step (1), as follows: heat pentabromotoluene and solvent to 50°C, stir for 2 hours, then crystallize at a low temperature at 5°C, and centrifuge the product to obtain pure white pentabromotoluene It can reach 99.5%. Among them, carbon tetrachloride is used as solvent, and th...

Embodiment 3

[0045] A method for industrialized preparation of high-purity and high-stability polypentabromobenzyl acrylate, comprising the following steps:

[0046] (1) Synthesize light-colored pentabromotoluene by controlling the low-temperature reaction, as follows: put bromine into the reaction kettle, control the reaction temperature at 5°C, control the weight ratio of toluene and bromine to 1:21, and control the toluene at 8h The dropwise addition is completed, and then the heat preservation reaction is carried out. After the reaction is completed, excess bromine is evaporated, centrifuged, and the material is washed to neutrality to obtain pentabromotoluene;

[0047] (2) Purify the pentabromotoluene obtained in step (1), as follows: heat pentabromotoluene and solvent to 45°C, stir for 2 hours, then crystallize at a low temperature at 3°C, and centrifuge the product to obtain pure white pentabromotoluene It can reach 99.5%. Among them, one or two of dichloroethane, dichloromethane, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com