Preparation method for high-abrasion-resistance hard alloy

A hard alloy, high wear-resistant technology, applied in the field of preparation of high wear-resistant hard alloy, can solve the problems of poor wear resistance and low hardness, and achieve the effect of good wear resistance, high hardness and enhanced wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

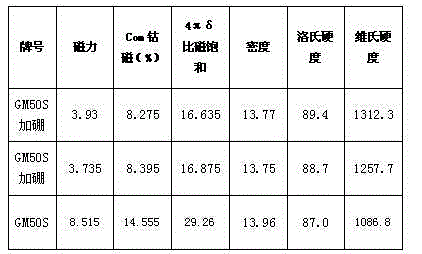

Embodiment 1

[0023] (1) Select 83 parts of WC powder with a Fischer particle size of 1.2um, 10 parts of Co powder with a Fischer particle size of 0.6, 0.7 parts of B powder, and 0.2 parts of C powder according to the material formula;

[0024] (2) Choose a 1Kg stirring ball mill, first add B powder, C powder and Co powder, add hexane at a ratio of 400ml / kg as the grinding medium, add grinding balls at a ratio of 5:1, and carry out stirring and grinding. The diameter of the grinding ball D7, the stirring speed of the ball mill is 480rpm, the filling factor is 0.65, and the grinding is for 1 hour;

[0025] (3) Then add tungsten carbide and grind for 3 hours to form a slurry to form a slurry;

[0026] (4) Filtration and drying, the mesh number of filtration is 40 mesh, and the drying temperature is 65°C to make cemented carbide mixture particles;

[0027] (5) Molding, extrusion or injection molding of cemented carbide mixture particles to make cemented carbide blanks;

[0028] (6) Put the c...

Embodiment 2

[0030] (1) Select 90 parts of WC powder with a Fischer particle size of 2.0um, 17 parts of Co powder with a Fischer particle size of 1.0um, 1.0 parts of B powder, and 1.0 parts of C powder according to the material formula;

[0031] (2) Choose a 1Kg stirring ball mill, first add B powder, C powder and Co powder, add hexane at a ratio of 400ml / kg as the grinding medium, add grinding balls at a ratio of 5:1, and carry out stirring and grinding. The diameter of the grinding ball D7, the stirring speed of the ball mill is 480rpm, the filling factor is 0.65, and the grinding is for 1 hour;

[0032] (3) Then add tungsten carbide and grind for 3 hours to form a slurry to form a slurry;

[0033] (4) Filtration and drying, the mesh number of filtration is 50 mesh, and the drying temperature is 95°C to make cemented carbide mixture particles;

[0034] (5) Molding, extrusion or injection molding of cemented carbide mixture particles to make cemented carbide blanks;

[0035] (6) Put the...

Embodiment 3

[0037] (1) Select 88 parts of WC powder with a Fischer particle size of 1.5um, 15 parts of Co powder with a Fischer particle size of 0.8um, 0.8 parts of B powder, and 0.5 parts of C powder according to the material formula;

[0038] (2) Choose a 1Kg stirring ball mill, first add B powder, C powder and Co powder, add hexane at a ratio of 400ml / kg as the grinding medium, add grinding balls at a ratio of 5:1, and carry out stirring and grinding. The diameter of the grinding ball D7, the stirring speed of the ball mill is 480rpm, the filling factor is 0.65, and the grinding is for 1 hour;

[0039] (3) Then add tungsten carbide and grind for 3 hours to form a slurry to form a slurry;

[0040] (4) Filtration and drying, the mesh number of filtration is 45 mesh, and the drying temperature is 80°C to make cemented carbide mixture particles;

[0041] (5) Molding, extrusion or injection molding of cemented carbide mixture particles to make cemented carbide blanks;

[0042] (6) Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com