Preparing method for in-site growth of titanium dioxide nanometer array film on surface of metal

A titanium dioxide, nano-array technology, applied in metal material coating process, solid-state chemical plating, coating and other directions, can solve the problems of reliability, narrow selection of matrix materials, etc., achieve good biological activity, simple preparation method, Good reproducibility of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

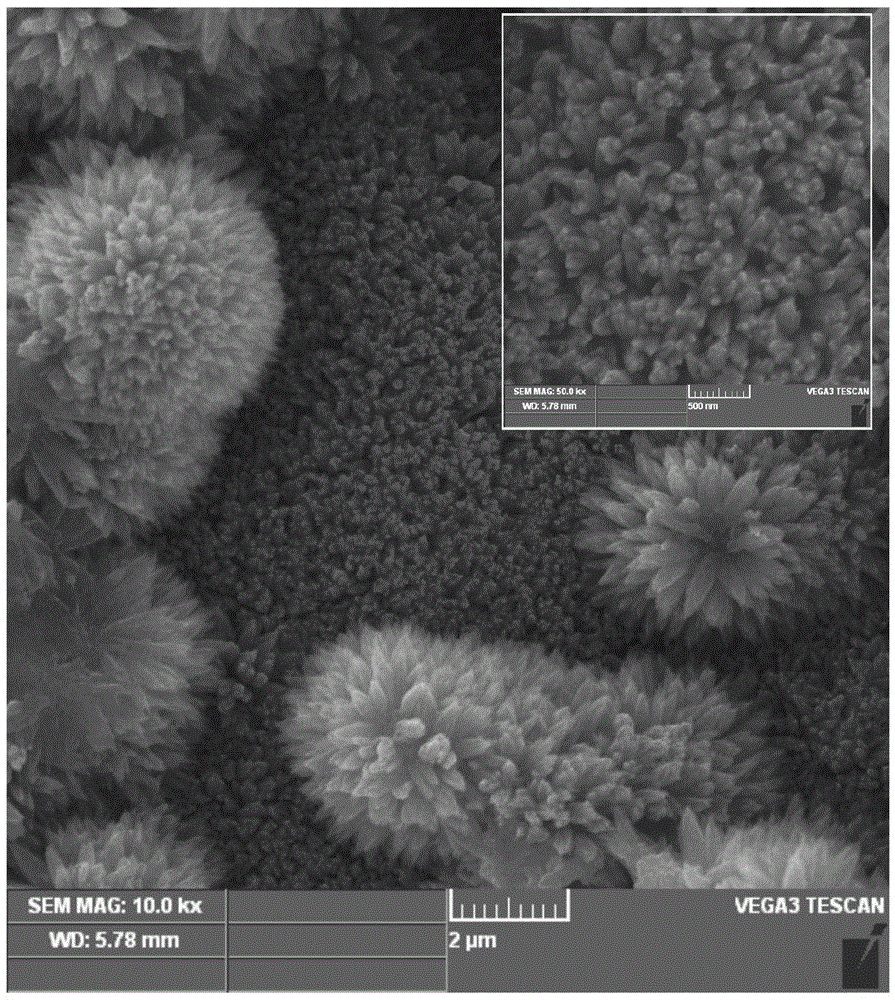

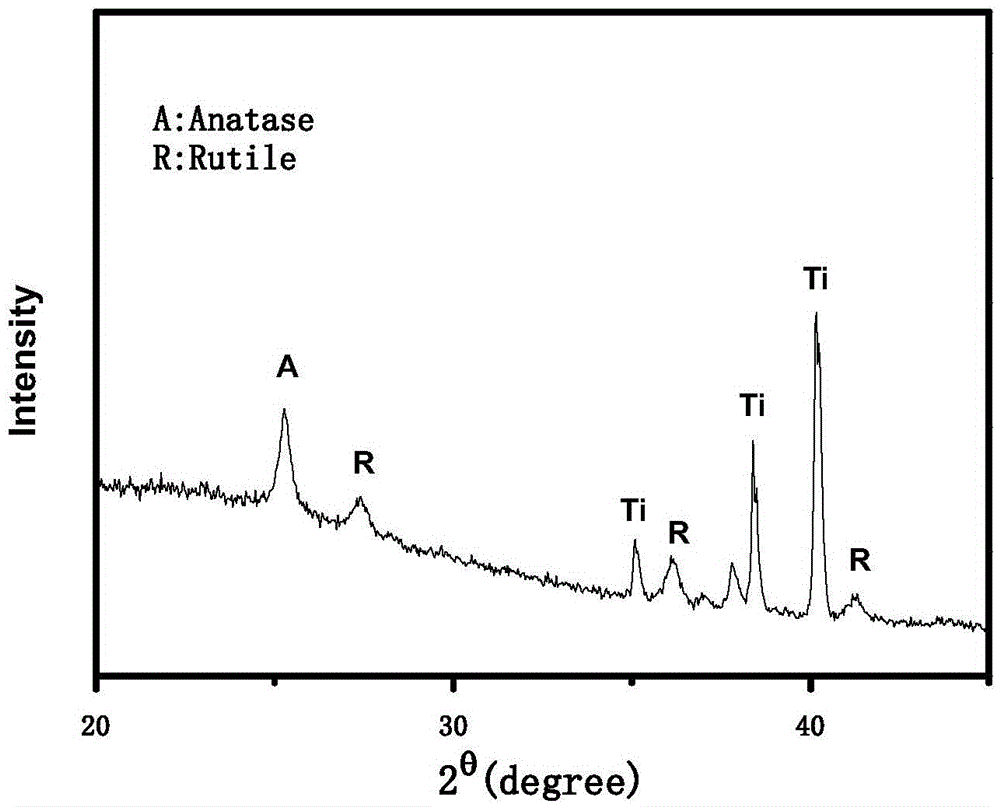

[0033] refer to figure 1 with figure 2 , a method for preparing a titanium dioxide nano-array film grown in situ on a metal surface, the method comprising the steps of:

[0034] 1. Preparatory work: Clean the pure titanium of 10×10×0.1mm with acetone and deionized water in turn for 3 to 4 times, and place it in H 2 o 2 Soak in (30%wt) at 80°C for 1 hour, take it out and wash it for later use.

[0035] 2. Solution preparation: Add 61.54g of hydrochloric acid into 200ml of deionized water and mix thoroughly, take 0.78g of H 2 o 2 (30%wt) was added acidic aqueous solution, and 0.90g of titanium oxysulfate TiOSO 4 Powder added H 2 o2 For an acidic solution, take 16.35g of dehydrated ethanol and add the mixed solution, and make the volume 300ml with deionized water to obtain 0.02mol / LTiOSO 4 Handling solution.

[0036] 3. Reaction steps: put pure titanium and treatment solution in a container at the same time, react at 170°C for 2 hours, take out the substrate after the re...

Embodiment 2

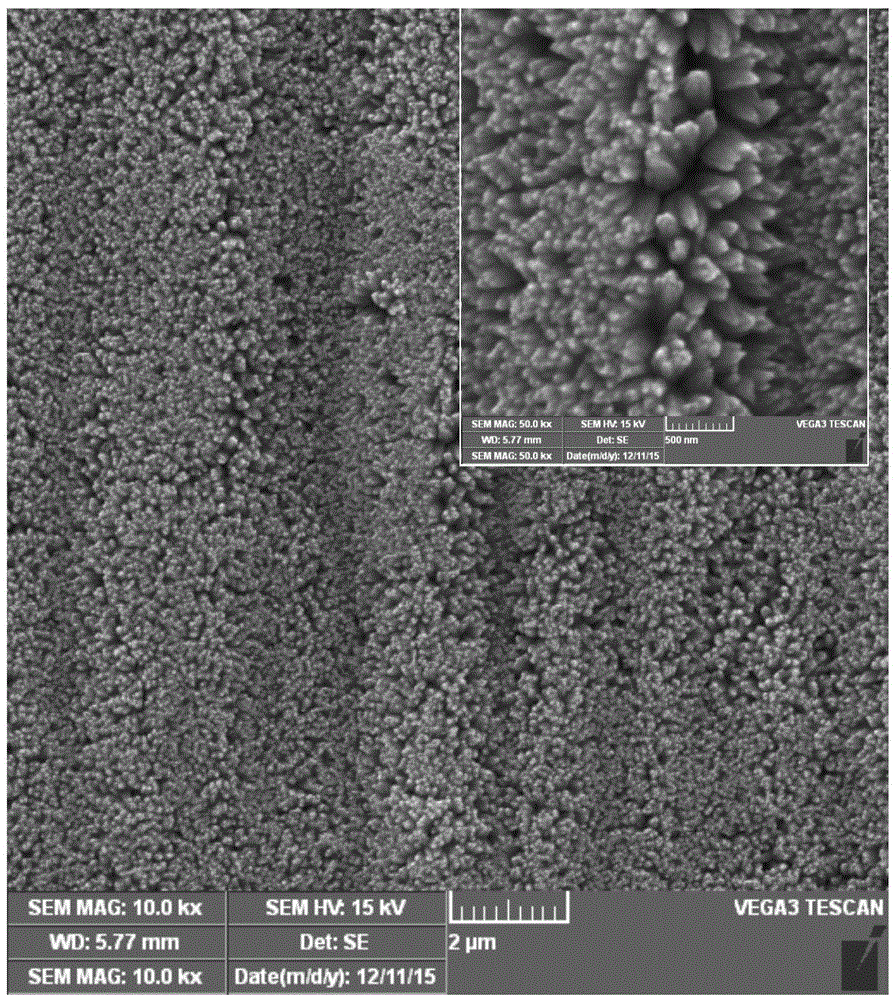

[0039] refer to image 3 with Figure 4 , a method for preparing a titanium dioxide nano-array film grown in situ on a metal surface, the method comprising the steps of:

[0040] 1, preparatory work: with embodiment 1;

[0041] 2. Solution preparation: Add 61.54g of hydrochloric acid into 200ml of deionized water and mix thoroughly, take 5.4g of TiCl 3 Add an acidic aqueous solution, take 16.35g of absolute ethanol and add to the mixed solution, and set the volume to 300ml with deionized water to obtain 0.02mol / LTiCl 3 Handling solution.

[0042] 3. Reaction steps: put pure titanium and treatment solution in a container at the same time, react at 170°C for 2 hours, take out the substrate after the reaction, and wash with deionized water to obtain a titanium dioxide nano-array film on the surface of the substrate.

Embodiment 3

[0044] refer to Figure 5 , a method for preparing a titanium dioxide nano-array film grown in situ on a metal surface, the method comprising the steps of:

[0045] 1. Preparation: Clean 10×10×0.1mm Ti-6Al-4V with acetone and deionized water in turn for 3 to 4 times, and place in H 2 o 2 Soak in (30%wt) at 80°C for 1 hour, take it out and wash it for later use.

[0046] 2. Solution preparation: Add 61.54g of hydrochloric acid into 200ml of deionized water and mix thoroughly, take 0.78g of H 2 o 2 (30%wt) was added acidic aqueous solution, and 0.90g of TiOSO 4 Powder added H 2 o 2 For acidic solution, take 16.35g of dehydrated ethanol and add the mixed solution, make 300ml of deionized water to obtain 0.02mol / LTiOSO 4 Handling solution.

[0047] 3. Reaction steps: put Ti-6Al-4V and the treatment solution in the container at the same time, react at 170°C for 2 hours, take out the substrate after the reaction is completed, and after cleaning with deionized water, titanium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com