Ionic induction type artificial skin array structure and preparation method thereof

An array structure and artificial skin technology, applied in the manufacture of tools, textiles, fabrics, etc., can solve the problems of difficult arraying, individual measurement, and insufficient sensitivity to small local deformations, and achieve the effect of strong sensing ability and sensitive response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment prepares the ion-sensing type artificial skin array structure based on metal wire and Nafion ionic membrane material according to the following steps:

[0043] (1) Adhesive sheet, copper wire and Nafion D520 (5%) solution (produced by DuPont, USA) were prepared, and the copper wire (about 150 μm in diameter and 10 cm in length) was directly used as a flexible fiber electrode.

[0044] (2) Use Nafion D520 (5%) solution (produced by DuPont, USA) as polyelectrolyte solution, drop it on copper wire, bake at 50° C. for 3 hours, evaporate to form a film, form a sheath, and make a composite electrode fiber;

[0045] (3) Using the glass plate as the base, first arrange three composite electrode fibers in parallel on the glass plate, the distance between adjacent composite electrode fibers is 5mm, and the ends are fixed with two adhesive sheets. Then, the other three composite electrode fibers were arranged vertically crossing at 90° on the composite elect...

Embodiment 2

[0050] The present embodiment prepares the ion-sensing type artificial skin array structure based on silver-plated fiber and Nafion ion membrane material according to the following steps:

[0051] (1) Soak several fiber filaments in the Ag nanoparticle dispersion, then evaporate the solvent to obtain silver-plated fibers as flexible fiber electrodes;

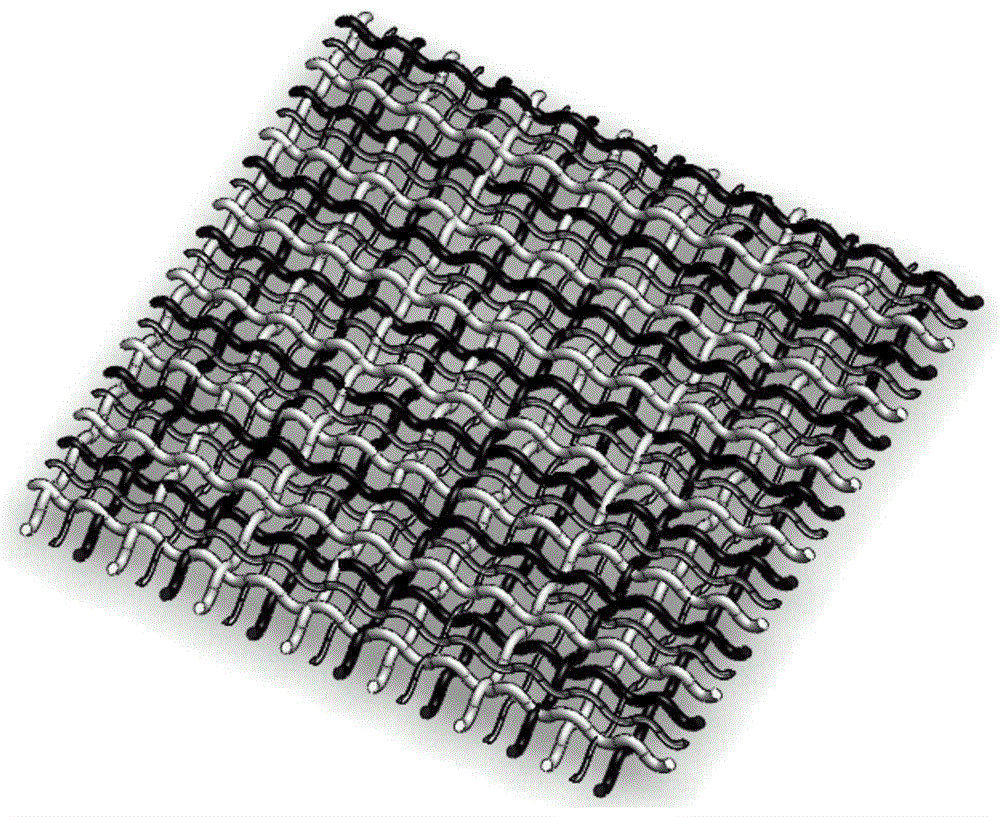

[0052] (2) Use such as Figure 5 In the composite electrode fiber production device shown, open the valve 4 through the valve handle 5, insert the flexible fiber electrode 6 into the heating mold 2, close the valve 4, place it horizontally, and then pass the Nafion D520 (5%) solution (produced by DuPont, USA) through The funnel is poured into the heating mold from the feed port 1, and heated by the heating sheet 3. First, it is kept at 80°C for 30 minutes, then the temperature is raised to 120°C for 6 hours, and finally raised to 140°C and kept for 30 minutes. After the device is cooled, add an appropriate amount of deionized w...

Embodiment 3

[0057] In this example, an ion-sensing artificial skin array structure composed of composite electrode fibers and flexible fiber electrodes is prepared according to the following steps:

[0058] (1) prepare silver-plated fiber by the mode in embodiment 2, as flexible fiber electrode 6;

[0059] (2) Use NafionD520 (5%) solution (produced by DuPont, USA) as a polyelectrolyte solution, drop it on the silver-plated fiber, bake at 50°C for 3 hours, evaporate to form a film, form a sheath, and make a composite electrode fiber 7;

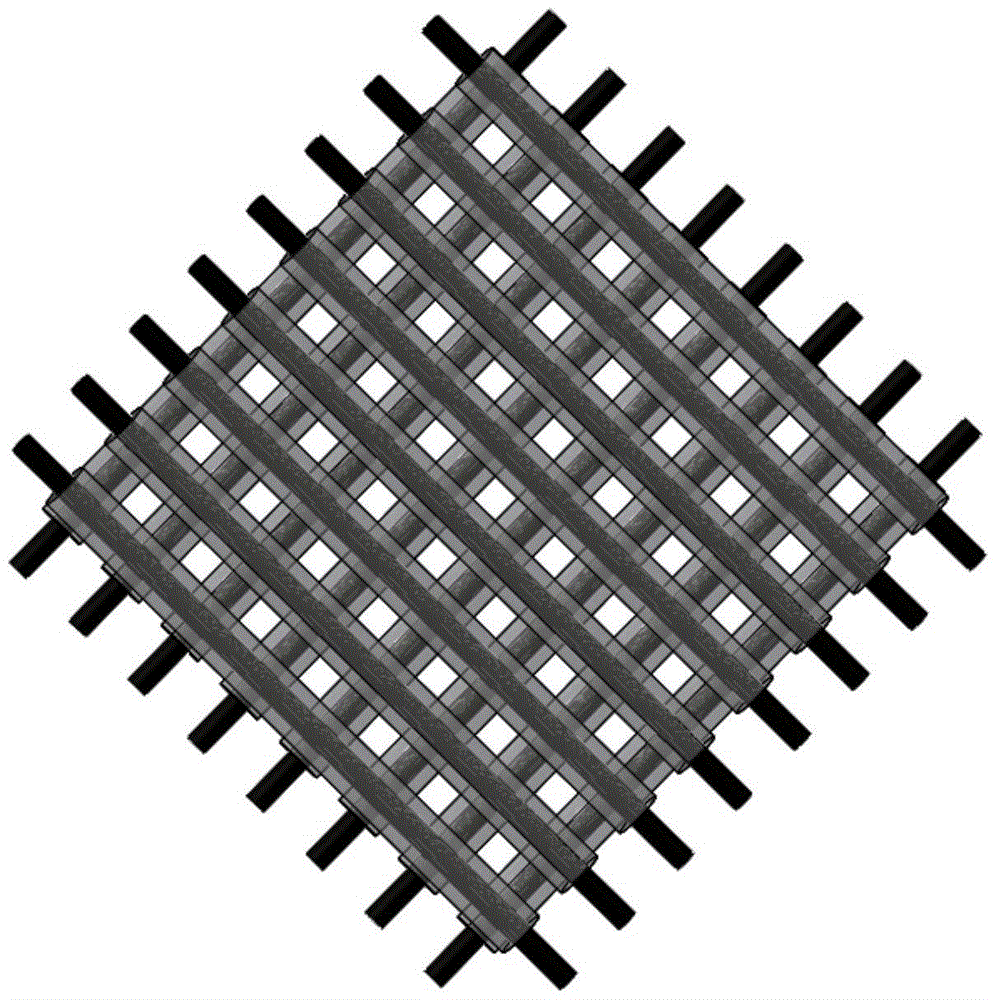

[0060] (3) if Figure 8 (a) and Figure 8 As shown in (b), the composite electrode fiber 7 is used as the lower layer, and the flexible fiber electrode 6 is used as the upper layer, and the two layers are vertically arranged in an array structure; Pressing each other at the contact points to form an ion-sensing artificial skin array structure;

[0061] (4) Soak the ion-sensing artificial skin array structure made in step (3) in 0.1mol / L HCl for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com