Electrospinning skin-core single fiber with axially equivalent piezoelectric property as well as preparation method and application thereof

A piezoelectric performance and electrospinning technology, applied in the field of single fiber and its preparation, can solve the problems of long receiving distance, unstable and disturbed electrospinning jet flow, and limit the application field of nanofibers, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The spinning solution is 10% polyvinylidene fluoride / DMF solution, the propulsion speed is set to 1ml / h, the output voltage of the voltage generator is set to 15kV, and the copper wire with a diameter of 0.4mm is used as the receiving electrode to carry out the electrospinning experiment, and the obtained The thickness of the cortex was 50 μm.

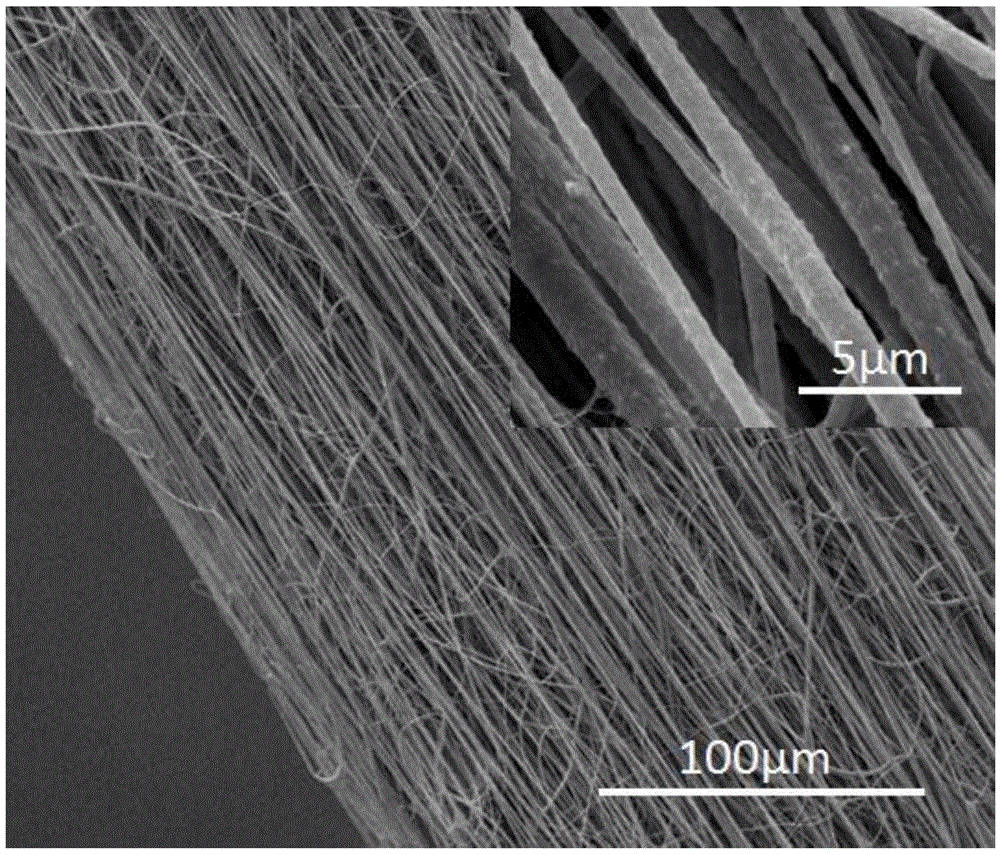

[0027] A uniform skin-core structure composite single fiber is obtained, the thickness of the fiber skin is about 0.1mm, and the bonding between the nanofibers is relatively tight. From the electron microscope photos ( figure 1 ), it can be seen that the polymer nanofibers are tightly packed, the thickness of the polymer nanofibers is relatively uniform, the orientation along the axial direction of the metal wire is high, and there is basically no twist. It has the same piezoelectric performance at all angles in the axial direction, and the peak value of instantaneous piezoelectric output per unit length of fiber is 5V / m·N.

Embodiment 2

[0029] The spinning liquid is 12% polyvinylidene fluoride / DMF solution, the propulsion speed is set to 0.8ml / h, the output voltage of the voltage generator is set to 18kV, and the copper wire with a diameter of 1mm is used as the receiving electrode for electrospinning experiments. A skin thickness of 65 μm and a polymer fiber diameter of 1 μm was obtained.

[0030] Obtain a uniform skin-core structure composite single fiber, the thickness of the fiber skin is 0.2mm, the bonding between the nanofibers is very tight, the polymer nanofibers are tightly packed, the thickness of the polymer nanofibers is relatively uniform, and the orientation is aligned along the wire axis high degree. It has the same piezoelectric performance at all angles in the axial direction, and the peak value of instantaneous piezoelectric output per unit length of fiber is 12V / m·N.

Embodiment 3

[0032] The spinning solution is 8% polyvinylidene fluoride / DMF solution, the propulsion speed is set to 1.5ml / h, the output voltage of the voltage generator is set to 15kV, and the electrospinning experiment is carried out with a carbon fiber with a diameter of 0.1mm as the receiving electrode. The thickness of the obtained skin layer was 40 μm, and the diameter of the polymer fiber was 800 nm.

[0033] A uniform skin-core structure composite single fiber is obtained, the thickness of the fiber skin is 0.4mm, the bonding between the nanofibers is very tight, the polymer nanofibers are tightly packed, the thickness of the polymer nanofibers is relatively uniform, and the orientation is aligned along the wire axis high degree. It has the same piezoelectric performance at all angles in the axial direction, and the peak value of instantaneous piezoelectric output per unit length of fiber is 15V / m·N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com