Manufacture method for light-weight soundproof brick

A manufacturing method and lightweight technology, applied to building materials, etc., can solve problems such as wall weight and structural load burden, and achieve the effects of cost reduction, energy saving, and excellent sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

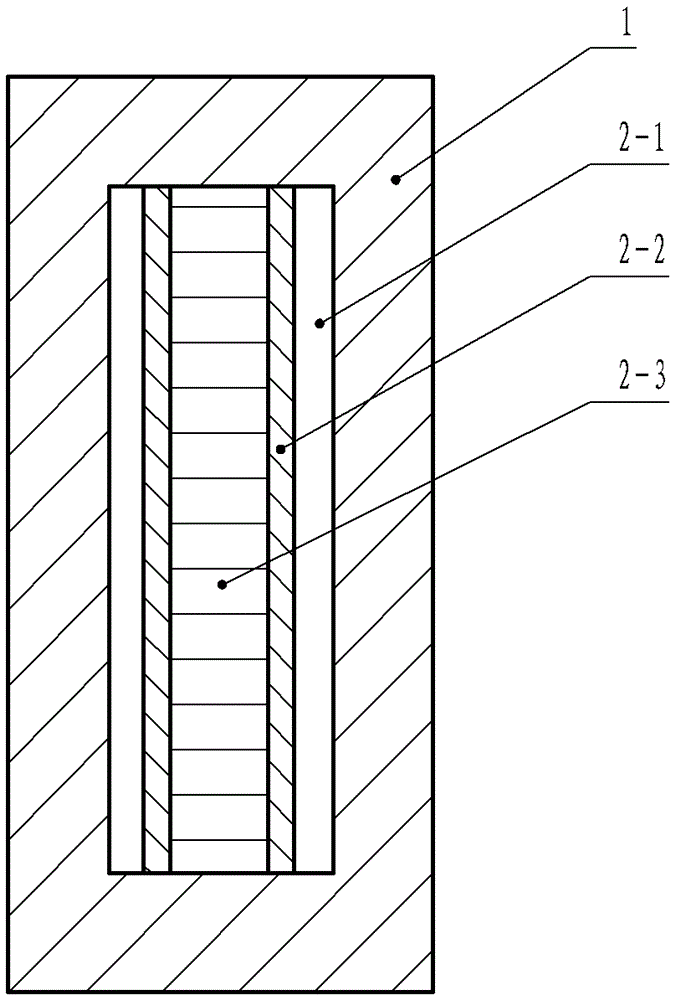

[0018] Such as figure 1 In the shown embodiment, the light-duty soundproof brick mold is 15cm thick, including the surface layer 1 and the filling body 2. The filling body 2 is divided into 5 layers. From the middle to both sides, there are sandwich layers 2-3 with a thickness of 2.5cm. A fixed layer 2-2 with a thickness of 1.25 cm and an air layer 2-1 with a thickness of 1.25 cm.

[0019] The production method is as follows:

[0020] A. Dewatering the sugar factory filter mud to a water content lower than 20% to obtain dewatered filter mud;

[0021] B, get 1 ton of dewatered filter mud obtained in step A, 3 tons of foamed cement, 2 tons of sand and mix evenly, add water and stir to get mixed mortar;

[0022] C. Inject the mixed mortar obtained in step B into the surface layer and fixed layer in the mold, inject the foam into the sandwich layer in the mold, extrude, dry naturally, and demould.

Embodiment 2

[0024] Mold of the present invention is identical with embodiment one, and manufacturing method is as follows:

[0025] A. Dewatering the sugar factory filter mud to a water content lower than 20% to obtain dewatered filter mud;

[0026] B, get 1 ton of dewatered filter mud obtained in step A, 2 tons of foamed cement, and 1 ton of sand and mix evenly, add water and stir to get mixed mortar;

[0027] C. Inject the mixed mortar obtained in step B into the surface layer and fixed layer in the mold, inject the mixture of foam and rock wool with a mass ratio of 1:1 into the sandwich layer in the mold, extrude, dry naturally, and demould. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com