Combined cooling heating and power supply system prediction control method based on state observer

A combined cooling, heating, power supply and state observer technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem of difficult to obtain control quality, insufficient control strategy, and difficult to obtain satisfactory control by traditional control methods Effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solution of the present invention will be further introduced below in combination with specific embodiments.

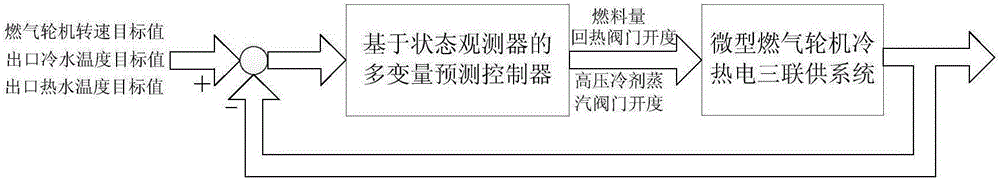

[0057] The invention discloses a predictive control method for a combined cooling, heating and power supply system based on a state observer. The system block diagram is as follows figure 1 Shown, the inventive method comprises the following steps:

[0058]S1: Obtain the step response model of the micro gas turbine combined cooling, heating and power supply object. The dynamic characteristics of the CCHP system can be described by the transfer function model shown in formula (1):

[0059] y 1 ( s ) y 2 ( s ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com