Soft-package power battery module

A technology for power batteries and battery modules, which is applied in battery pack components, secondary batteries, and secondary battery repair/maintenance, etc. Reduce design cost and mold cost, save design and mold opening cost, and design the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

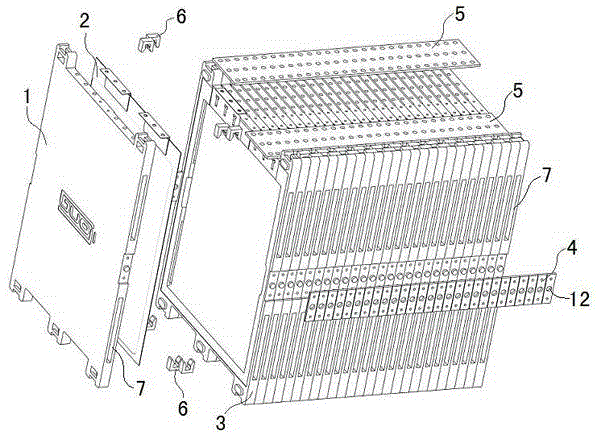

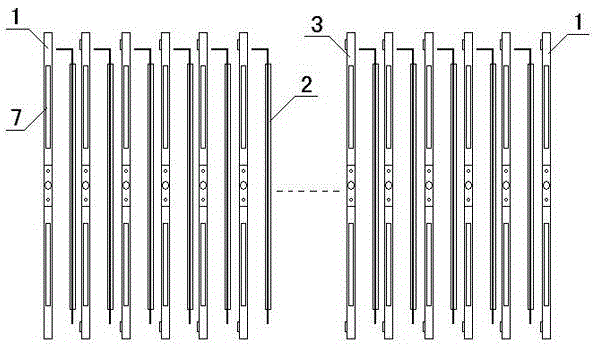

[0030] attached by figure 1 , 2 , 5: the battery module includes a bracket end cover 1, a battery cell 2, a bracket unit 3, a bracket side connecting plate 4, a battery cell conductive connecting piece 5 and a bracket connecting buckle 6, the multiple A bracket body 3 and bracket end caps 1 at both ends are assembled to form a bracket body through the bracket side connecting plate 4 and the bracket connection buckle 6, and the battery core 2 is embedded and fixed on the bracket end cover 1 Between the bracket monomer 3 and two adjacent bracket monomers 3, the bracket side connecting plate 4 is clamped and connected to the side of the assembled bracket end cover 1 and the bracket monomer 3, so that The electric core conductive connecting sheet 5 is divided into upper and lower layers, and the electrodes on each electric core 2 are connected together by a plurality of screws 13 (such as Figure 8 shown).

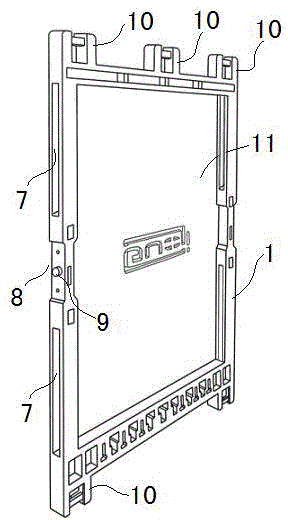

[0031] attached by image 3 , 4 As shown: the bracket end cover 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com