Anti-virus mask

An anti-virus and mask technology, applied in the field of anti-virus masks, can solve the problems of too large aperture, no national, industry and local standards for anti-virus masks, failure to meet anti-virus and other problems, so as to solve the problem of tightness and improve filtration. Virus effect, anti-leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

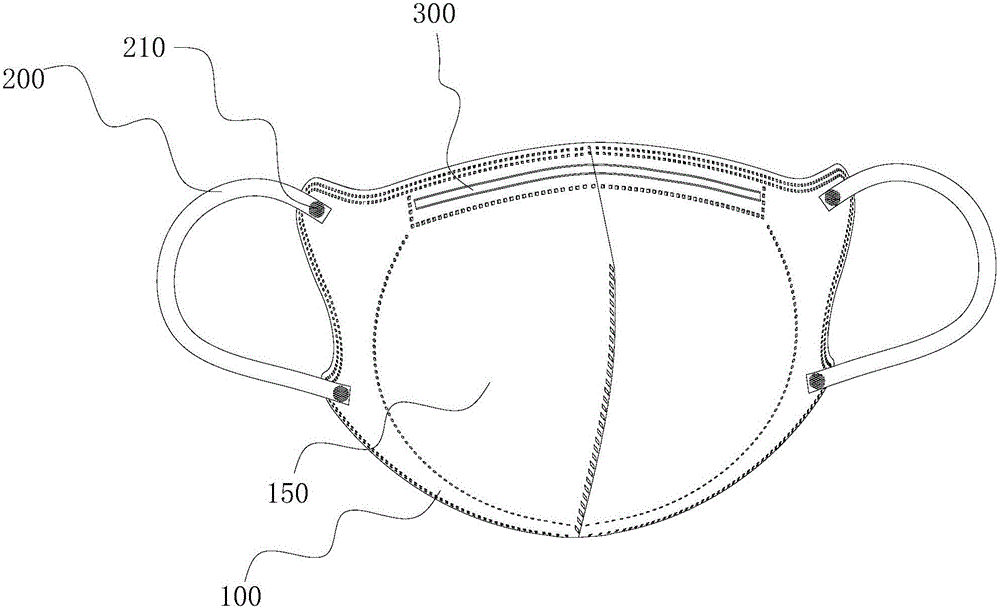

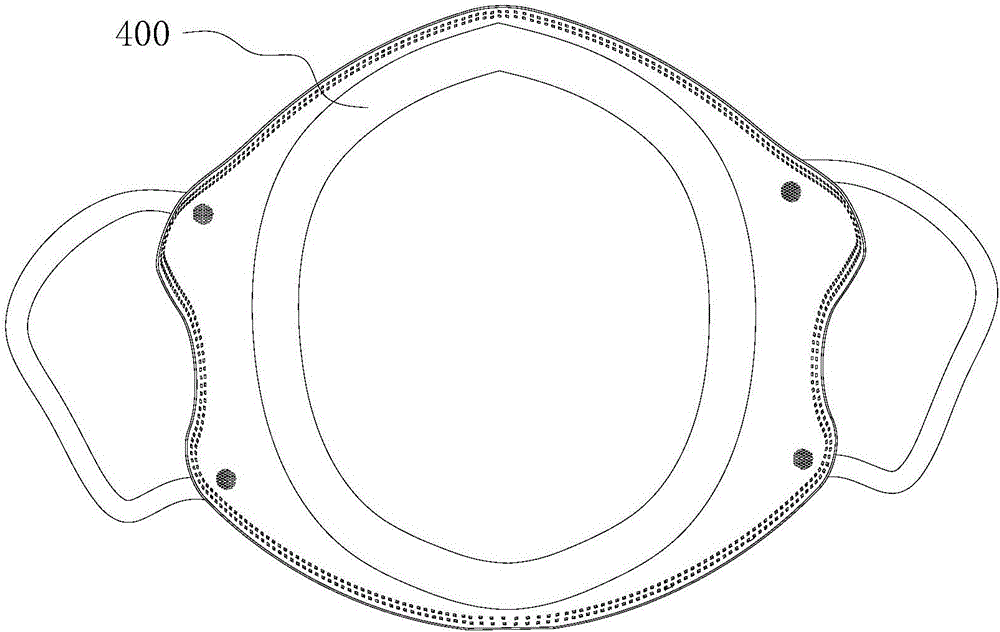

[0054] An anti-virus mask such as Figure 1-2 As shown, it includes a cover body 100 , a fixing belt 200 , a nose shaping strip 300 and a sealing ring 400 .

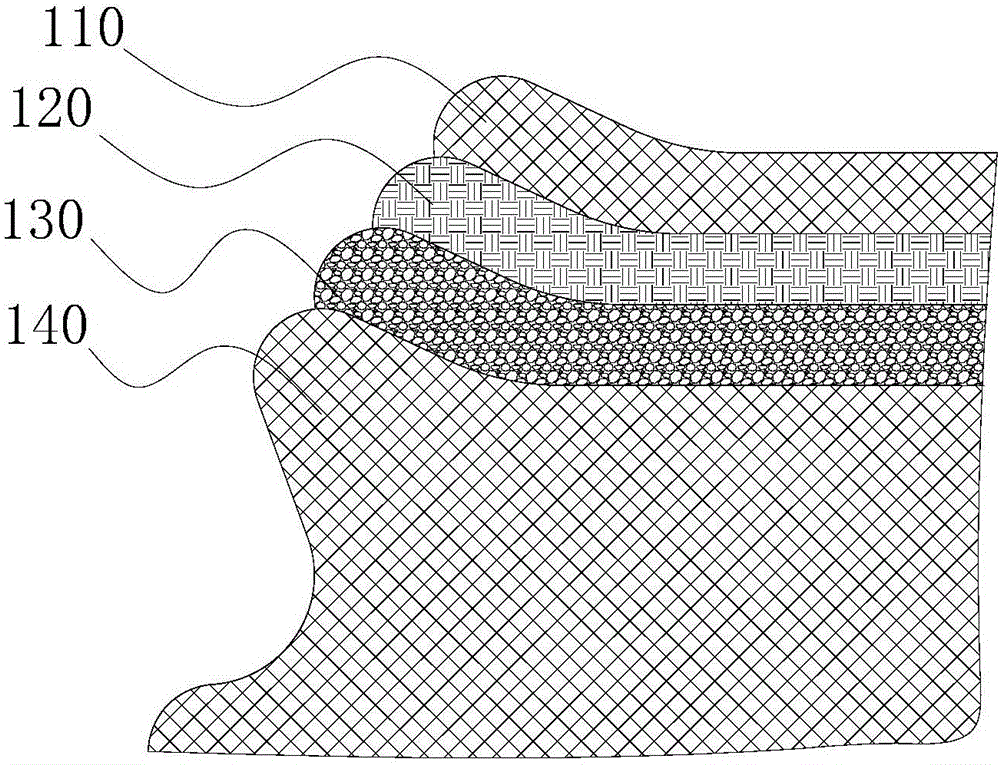

[0055] The cover body 100 includes a first spunbond fiber layer 110, a meltblown fiber layer 120, a nanofiber layer 130 and a second spunbond fiber layer 140 stacked in sequence, such as image 3 Shown; The fiber diameter in the first spunbond fiber layer and the second spunbond fiber layer is 1 μm-10 μm, the fiber diameter in the melt-blown fiber layer is 100nm-500nm, and the fiber diameter in the nanofiber layer is 50nm -150nm, the pore diameter of the nanofiber layer is 50nm-250nm.

[0056] In this embodiment, the fixing strap 200 is a ring-shaped ear strap, which is fixed on the cover body through ultrasonic welding points 210 by means of ultrasonic welding. , the interlayer of the cover body is provided with a nose shaping strip 300, which is kneaded according to the shape characteristics of different users' noses...

Embodiment 2

[0067] A kind of antivirus mask is basically the same as the antivirus mask in embodiment 1, the difference is:

[0068] The nanofiber layer is prepared by the following method:

[0069] 1. Preparation of spinning solution.

[0070] Polytetrafluoroethylene was dissolved in N,N-dimethylacetamide (DMAc) to prepare a spinning solution with a mass concentration of 10%.

[0071] 2. Electrospinning.

[0072] Add the prepared spinning liquid into the spinning liquid tank of the electrospinning machine, and control the electrospinning conditions as follows: voltage 25kV, the distance from the nanofiber outlet of the needleless electrospinning machine to the spinning roller 15cm, electrospinning is carried out. The spun nanofibers are directly compounded on the double-layer non-woven fabric of melt-blown polypropylene (PP) fiber layer / spun-bonded polypropylene (PP) fiber layer.

[0073]Then compound a layer of spun-bonded PP fiber layer on the formed nanofiber layer. Finally, a fi...

Embodiment 3

[0075] A kind of antivirus mask is basically the same as the antivirus mask in embodiment 1, the difference is:

[0076] The nanofiber layer is prepared by the following method:

[0077] 1. Preparation of spinning solution.

[0078] Polypropylene was dissolved in N,N-dimethylacetamide (DMAc) to prepare a spinning solution with a mass concentration of 10%.

[0079] 2. Electrospinning.

[0080] Add the prepared spinning liquid into the spinning liquid tank of the electrospinning machine, and control the electrospinning conditions as follows: voltage 25kV, the distance from the nanofiber outlet of the needleless electrospinning machine to the spinning roller 15cm, electrospinning is carried out. The spun nanofibers are directly compounded on the double-layer non-woven fabric of melt-blown polypropylene (PP) fiber layer / spun-bonded polypropylene (PP) fiber layer.

[0081] Then compound a layer of spun-bonded PP fiber layer on the formed nanofiber layer. Finally, a filter mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com