Method for preparing nitrogen-doped hollow mesoporous core-shell carbon spheres

A nitrogen-doped, hollow technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the cumbersome process of synthesizing hollow core-shell carbon materials and the inertness of the shell has not been effectively solved. Affecting material properties and other issues, to achieve the effect of low cost, simple operation and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

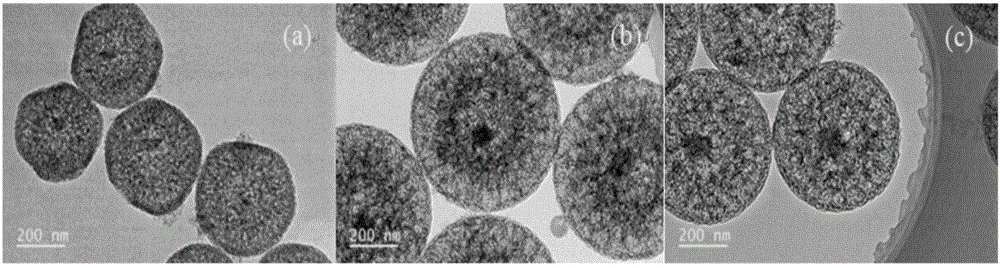

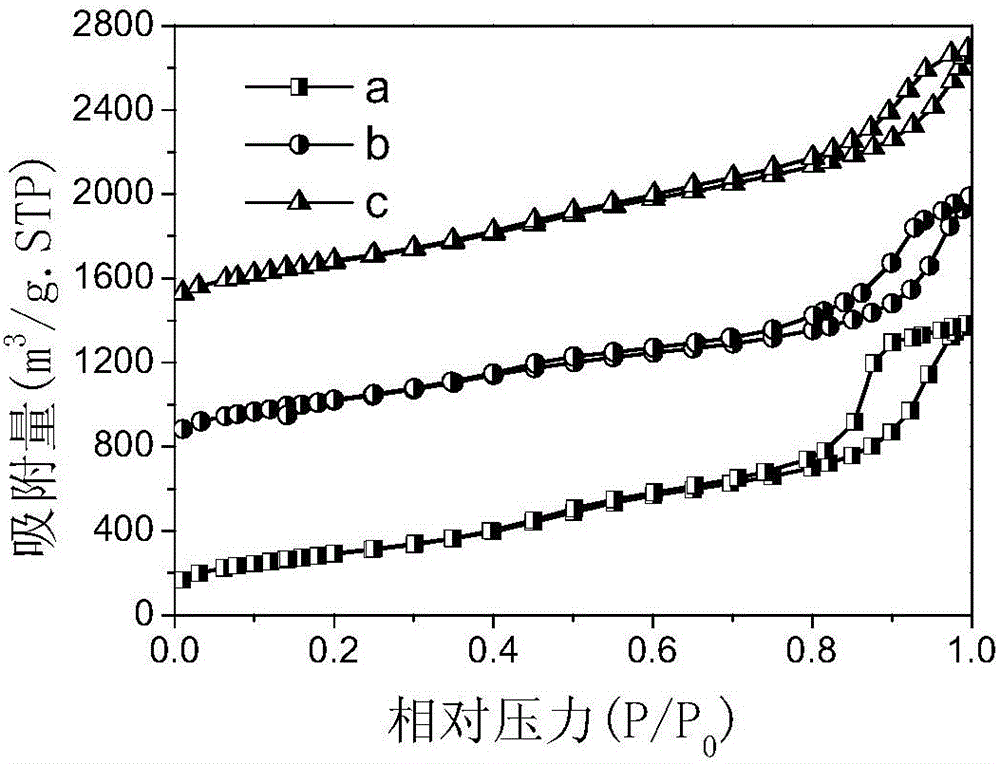

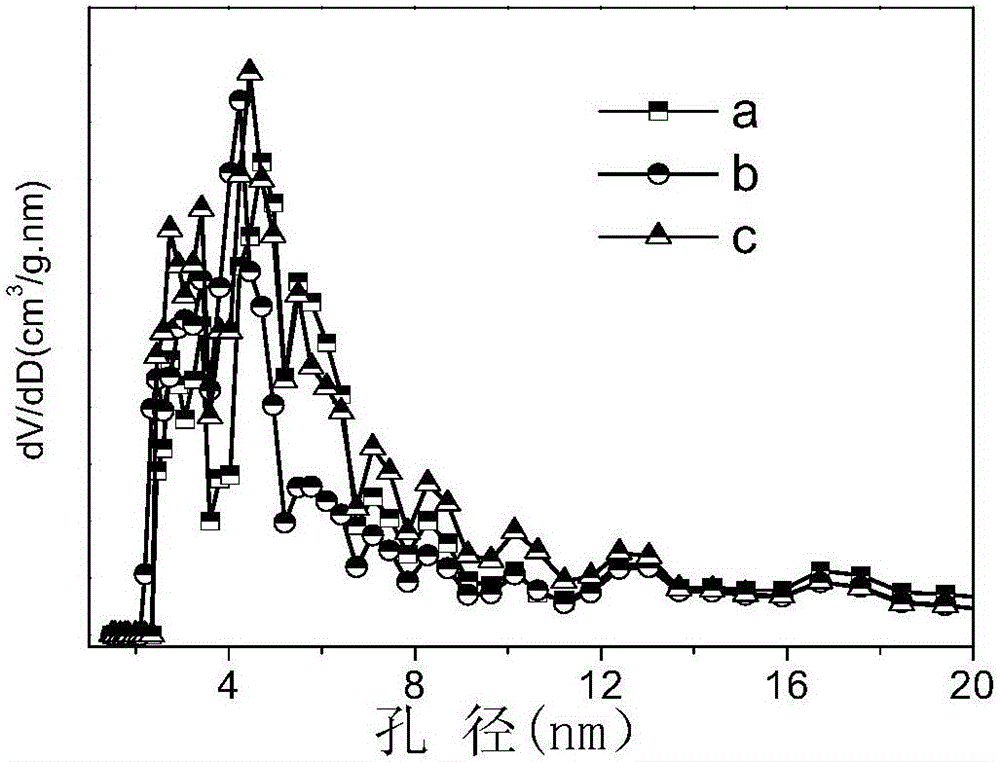

Embodiment 1

[0019] Step 1: Measure 100ml of deionized water, 40ml of ethanol and 0.2ml of ammonia water, and weigh 2g of cetyltrimethylammonium chloride in a beaker, stir magnetically in an oil bath at 70°C until cetyltrimethylammonium Methylammonium chloride was completely dissolved (15min).

[0020] Step 2: Accurately weigh 0.55g of resorcinol and add it to the beaker, then stir until it is completely dissolved (15min). Accurately weigh 0.74ml of formaldehyde solution with a mass fraction of 37%, and add 3ml of tetraethyl orthosilicate into the beaker at the same time (the solution in the beaker will quickly turn milky white), and stir magnetically in an oil bath at 70°C for 30min.

[0021] Step 3: Accurately weigh 0.3g of melamine and add it to the milky white solution described in the second step, stir in an oil bath at 70°C until it is completely dissolved (about 15 minutes), then add 0.55ml of formaldehyde solution with a mass fraction of 37%, Sealed with a rubber band and stirred ...

Embodiment 2

[0024] Step 1: Measure 100ml of deionized water, 40ml of ethanol and 0.5ml of ammonia water, and weigh 2g of cetyltrimethylammonium chloride in a beaker at the same time, stir magnetically in an oil bath at 70°C until cetyltrimethylammonium Methylammonium chloride was completely dissolved (15min).

[0025] Step 2: Accurately weigh 0.55g of resorcinol and add it to the beaker, then stir until it is completely dissolved (15min). Accurately weigh 0.74ml of formaldehyde solution with a mass fraction of 37%, and add 3ml of tetraethyl orthosilicate into the beaker at the same time (the solution in the beaker will quickly turn milky white), and stir magnetically in an oil bath at 70°C for 30min.

[0026] Step 3: Accurately weigh 0.3g of melamine and add it to the milky white solution described in the second step, stir in an oil bath at 70°C until it is completely dissolved (about 15 minutes), then add 0.55ml of formaldehyde solution with a mass fraction of 37%, Sealed with a rubber ...

Embodiment 3

[0029] Step 1: Measure 100ml of deionized water, 40ml of ethanol and 1ml of ammonia water, and weigh 2g of cetyltrimethylammonium chloride in a beaker, stir magnetically in an oil bath at 70°C until cetyltrimethylammonium Ammonium chloride was completely dissolved (15min).

[0030] Step 2: Accurately weigh 0.55g of resorcinol and add it to the beaker, then stir until it is completely dissolved (15min). Accurately weigh 0.74ml of formaldehyde solution with a mass fraction of 37%, and add 3ml of tetraethyl orthosilicate into the beaker at the same time (the solution in the beaker will quickly turn milky white), and stir magnetically in an oil bath at 70°C for 30min.

[0031] Step 3: Accurately weigh 0.3g of melamine and add it to the milky white solution described in the second step, stir in an oil bath at 70°C until it is completely dissolved (about 15 minutes), then add 0.55ml of formaldehyde solution with a mass fraction of 37%, Sealed with a rubber band and stirred at 70°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com