Microbial flocculant composition and preparation method thereof

A technology of microbial flocculant and composition, applied in the field of microbial flocculant composition and its preparation, can solve the problems of reduced flocculant activity and influence on bacterial growth, etc., and achieves good flocculation effect, remarkable effect, better flocculation effect and excellent flocculation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

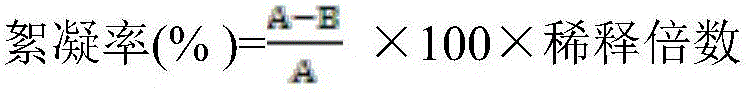

Examples

Embodiment 1

[0017] Example 1 Microbial flocculant composition of the present invention and preparation method thereof

[0018] A microbial flocculant composition, comprising the following raw materials in parts by weight: 30 parts of co-fermentation products of Curvularia lunae and Rhodococcus erythroflates, 50 parts of activated silicic acid, and 3 parts of polyoxyethylene.

[0019] Wherein the preparation method of the co-fermentation product of Curvularia crescenae and Rhodococcus erythroflates is a two-stage fermentation method, which specifically includes the following steps: after the fermentation medium is sterilized, insert 10% of Rhodococcus erythroflates seed fermentation liquid, control The fermentation temperature is 30°C and the ventilation volume is 1.5m 3 Cultivate under the condition of 40 hours per hour, insert 10% Curvularia lunata seed fermentation broth at this time, control the fermentation temperature to be 26°C, and the ventilation rate to be 1.8m 3 Cultivate for 2...

Embodiment 2

[0022] Example 2 Microbial flocculant composition of the present invention and preparation method thereof

[0023] A microbial flocculant composition, comprising the following raw materials in parts by weight: 40 parts of co-fermentation products of Curvularia lunae and Rhodococcus erythroflates, 95 parts of activated silicic acid, and 6 parts of polyoxyethylene.

[0024] Wherein the preparation method of the co-fermentation product of Curvularia crescenae and Rhodococcus erythroflates is a two-stage fermentation method, which specifically includes the following steps: after the fermentation medium is sterilized, insert 10% of Rhodococcus erythroflates seed fermentation liquid, control The fermentation temperature is 32°C and the ventilation volume is 1.7m 3 Cultivate under the condition of 44 hours per hour, insert 10% Curvularia lunata seed fermentation broth at this time, control the fermentation temperature to be 29°C, and the ventilation rate to be 2.2m 3 Cultivate for 3...

Embodiment 3

[0027] Example 3 Microbial flocculant composition of the present invention and preparation method thereof

[0028] A microbial flocculant composition, comprising the following raw materials in parts by weight: 35 parts of co-fermentation products of Curvularia lunae and Rhodococcus erythroflates, 75 parts of activated silicic acid, and 5 parts of polyoxyethylene.

[0029] Wherein the preparation method of the co-fermentation product of Curvularia crescenae and Rhodococcus erythroflates is a two-stage fermentation method, which specifically includes the following steps: after the fermentation medium is sterilized, insert 10% of Rhodococcus erythroflates seed fermentation liquid, control The fermentation temperature is 32°C and the ventilation volume is 1.6m 3 Cultivate under the condition of 42 hours per hour, insert 10% Curvularia lunata seed fermentation broth at this time, control the fermentation temperature to be 28°C, and the ventilation rate to be 2.0m 3 Cultivate for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com