Method for stopping wrinkles from being formed on surface of azobenzene thin film by light illumination

A kind of technology of azobenzene and thin film, which is applied in the direction of coating, etc., can solve the problems of inapplicability, achieve the effect of preventing material failure, improving the service life of materials, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) After mixing the PDMS prepolymer and cross-linking agent at a mass ratio of 10:1, stir fully to form a uniform prepolymer, degas the prepolymer in a vacuum pump, pour it into a petri dish, and heat it at 80°C Heating to crosslink.

[0019] (2) The PDMS elastomer obtained by step (1) cross-linking is subjected to oxygen plasma activation treatment;

[0020] (3) Spin-coat a tetrahydrofuran solution with a mass fraction of 2wt% PAzo on the activated PDMS in step (2), heat and dry to obtain a PDMS / PAzo soft-hard composite system;

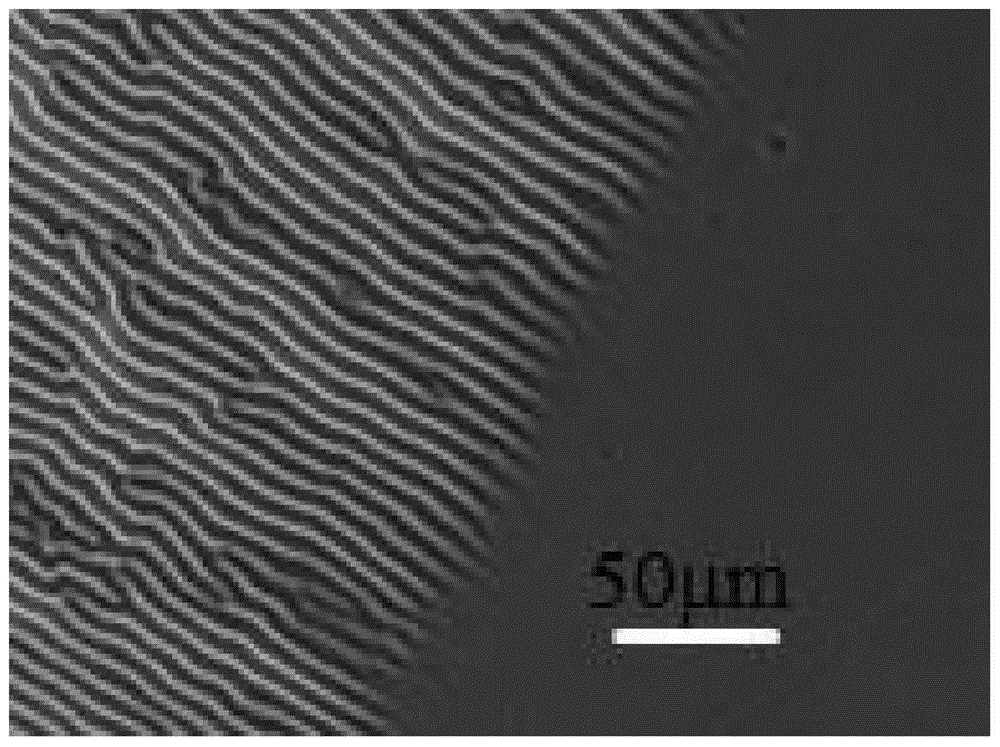

[0021] (4) Divide the PDMS / PAzo soft and hard composite system into two parts, and add 30mW / cm to one part 2 part of it is illuminated, and the other part is not. At the same time, an external stress of 0.15 MPa was applied to the entire PDMS / PAzo system, no wrinkles formed in the illuminated area, and wrinkles formed in the non-illuminated area.

Embodiment 2

[0023] (1) After mixing the PDMS prepolymer and cross-linking agent at a mass ratio of 10:1, stir fully to form a uniform prepolymer, degas the prepolymer in a vacuum pump, pour it into a petri dish, and heat it at 80°C Heating to crosslink.

[0024] (2) The PDMS elastomer obtained by step (1) cross-linking is subjected to oxygen plasma activation treatment;

[0025] (3) Spin-coat a tetrahydrofuran solution with a mass fraction of 2wt% PAzo on the activated PDMS in step (2), heat and dry to obtain a PDMS / PAzo soft-hard composite system;

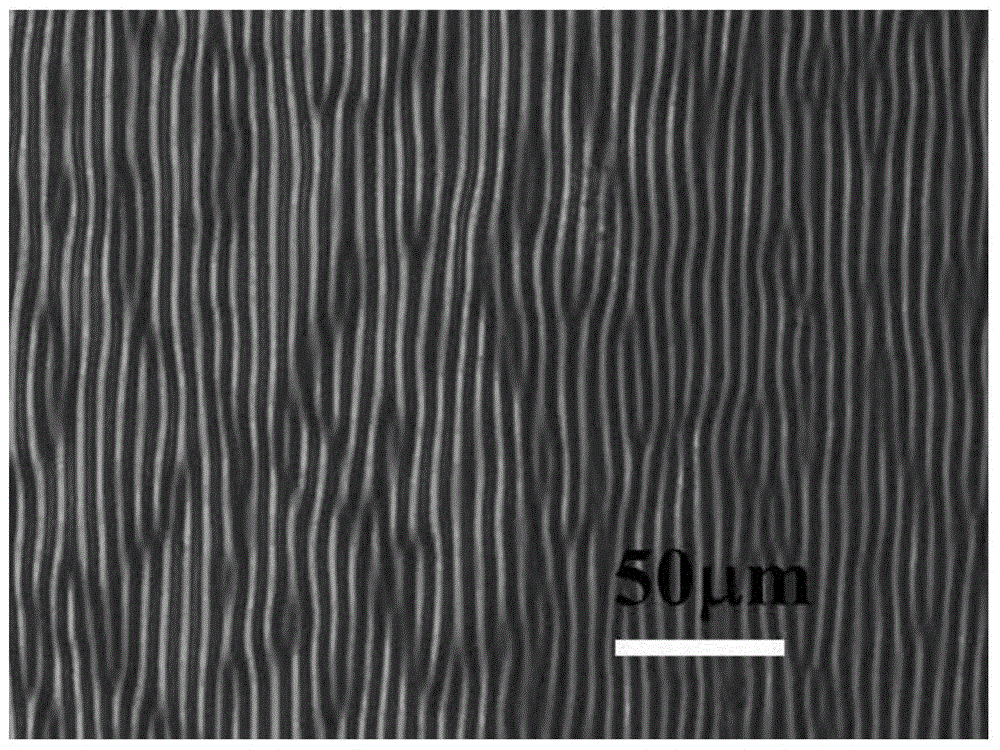

[0026] (4) Divide the PDMS / PAzo soft and hard composite system into two parts, one part is added with 10mW / cm 2 part of it is illuminated, and the other part is not. At the same time, an external stress of 0.15MPa was applied to the entire PDMS / PAzo system, and wrinkles were formed in both the illuminated area and the non-illuminated area, but the wrinkle cycle in the illuminated area was smaller than that in the non-illuminated area.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com