Bio-oil and preparation method thereof

A technology of biomass oil and biomass, which is applied in the direction of biofuel, petroleum industry, special form of dry distillation, etc., can solve the problems of high production cost and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention provides a kind of preparation method of biomass oil, comprises the following steps,

[0037] 1) After mixing the pulverized lignocellulosic biomass and an aqueous ammonia source substance solution, the loaded biomass is obtained;

[0038] 2) Under anaerobic conditions, after pyrolyzing the loaded biomass obtained in the above steps, pyrolysis gas is obtained;

[0039] 3) After condensing the pyrolysis gas obtained in the above steps, biomass oil is obtained.

[0040] In the present invention, the selection and ratio of the raw materials and other preferred principles are consistent with those of the aforementioned biomass oil, and will not be repeated here.

[0041] In the invention, firstly, the pulverized lignocellulosic biomass is mixed with an ammonia source substance aqueous solution to obtain a loaded biomass.

[0042] The present invention is not particularly limited to the lignocellulosic biomass. The lignocellulosic biomass known to those skill...

Embodiment 1

[0054] Configure urea with a mass fraction of 10%, then immerse 200g of rice husk in 1000ml of the above solution, stir for 4 hours under the action of a magnetic stirrer, then filter and dry at 50°C for 24 hours to obtain urea-loaded biomass raw material.

[0055] Weigh 20g of loaded urea-type biomass raw material and pyrolyze it for 20min at 470°C under a nitrogen atmosphere to obtain a liquid (biomass oil) yield of 51.3%.

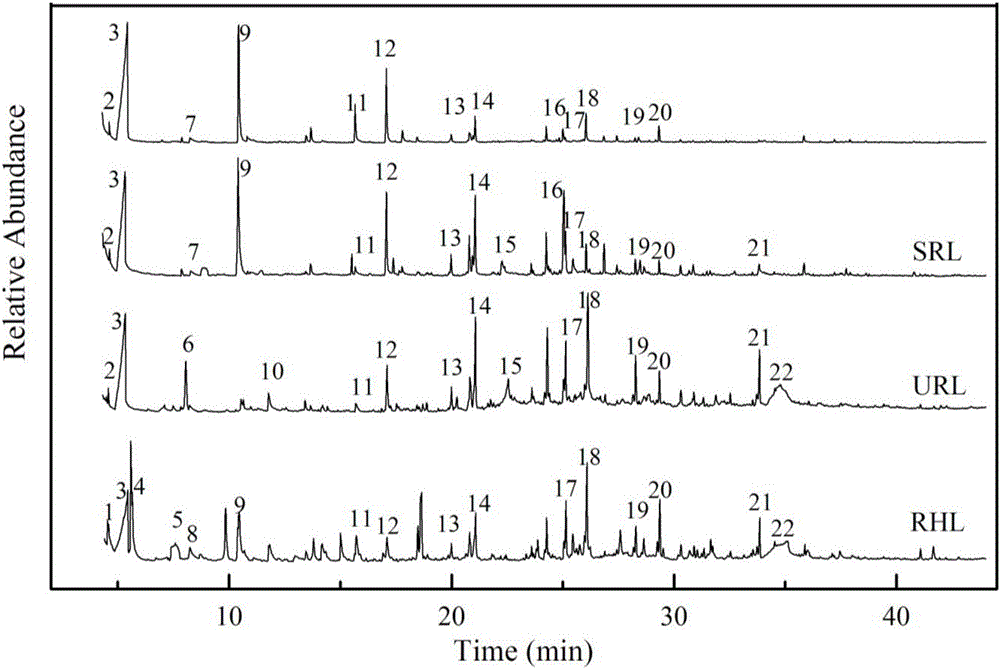

[0056] The bio-oil obtained in the above steps is detected, and gas chromatographic analysis shows that the bio-oil does not contain small molecule carbonyl compounds such as glycolaldehyde and methylglyoxal, and the content of nitrogen-containing heterocyclic compounds in the organic liquid product is 8.5%.

Embodiment 2

[0058] Configure ammonium dihydrogen phosphate with a mass fraction of 15%, then immerse 200g of rice husk in 1000ml of the above solution, stir for 3 hours under the action of a magnetic stirrer, then filter and dry at 80°C for 16 hours to obtain loaded phosphoric acid Ammonium dihydrogen type biomass raw material.

[0059] Weighed 20 g of ammonium dihydrogen phosphate-type biomass raw material, and pyrolyzed it at 490° C. for 15 minutes under a nitrogen atmosphere to obtain a liquid product yield of 38.3%.

[0060] The bio-oil obtained in the above steps is detected, and gas chromatographic analysis shows that the bio-oil does not contain small molecular carbonyl compounds such as glycolaldehyde and methylglyoxal, and the content of nitrogen-containing heterocyclic compounds in the organic liquid product is 5.65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com