Highland barley nutrition rice wine and brewing method thereof

A technology of highland barley and rice wine, applied in the field of rice wine brewing, can solve the problems of serious homogeneity, lack of innovative and healthy rice wine products, etc., achieve the effects of simple brewing process, large-scale industrial production, and improvement of nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

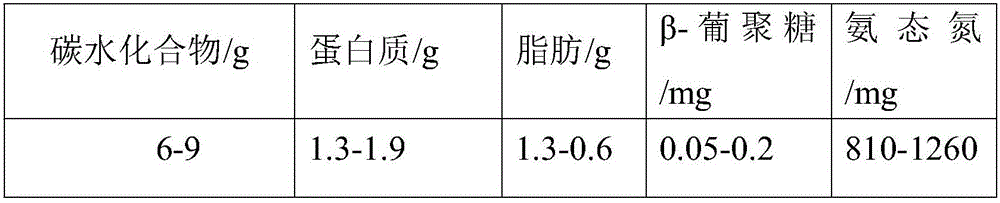

Image

Examples

Embodiment 1

[0016] Step 1, shelling, extruding and crushing the highland barley purchased from the market;

[0017] Step 2, after washing the crushed highland barley, add water to soak, wait until the acidity of the soaking water reaches 2g / L, stop soaking, and then cook under normal pressure for 30 minutes to obtain the highland barley as a fermentation raw material;

[0018] Step 3: inoculate the BR30 strain of Saccharomyces cerevisiae on the wort medium, shake and culture it for 12 hours at a culture temperature of 30° C. to obtain the primary seed liquid, and carry out secondary expansion cultivation of the primary seed liquid under the same conditions , to obtain the secondary seed liquid, after the secondary seed liquid was centrifuged at 4000rpm for 10 minutes, the thalline was collected, and the thalline was made into suspended thalline with sterile water, and the thalline concentration obtained was 10 9 cfu / mL inoculum;

[0019] Step 4, put into the sterilized container the high...

Embodiment 2

[0024] Step 1, shelling, extruding and crushing the highland barley purchased from the market;

[0025] Step 2, after washing the crushed highland barley, add water to soak, wait until the acidity of the soaking water reaches 4g / L, stop soaking, and then cook under normal pressure for 30 minutes to obtain the highland barley as a fermentation raw material;

[0026] Step 3: inoculate the BR30 strain of Saccharomyces cerevisiae on the wort medium, shake and culture it for 12 hours at a culture temperature of 30° C. to obtain the primary seed liquid, and carry out secondary expansion cultivation of the primary seed liquid under the same conditions , to obtain the secondary seed liquid, after the secondary seed liquid was centrifuged at 4000rpm for 10 minutes, the thalline was collected, and the thalline was made into suspended thalline with sterile water, and the thalline concentration obtained was 10 9 cfu / mL inoculum;

[0027] Step 4, put into the sterilized container the high...

Embodiment 3

[0032] Step 1, shelling, extruding and crushing the highland barley purchased from the market;

[0033] Step 2, after washing the crushed highland barley, add water to soak, wait until the acidity of the soaking water reaches 4g / L, stop soaking, and then cook under normal pressure for 30 minutes to obtain the highland barley as a fermentation raw material;

[0034] Step 3: inoculate the BR30 strain of Saccharomyces cerevisiae on the wort medium, shake and culture it for 12 hours at a culture temperature of 30° C. to obtain the primary seed liquid, and carry out secondary expansion cultivation of the primary seed liquid under the same conditions , to obtain the secondary seed liquid, after the secondary seed liquid was centrifuged at 4000rpm for 10 minutes, the thalline was collected, and the thalline was made into suspended thalline with sterile water, and the thalline concentration obtained was 10 9 cfu / mL inoculum;

[0035] Step 4, put into the sterilized container the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com