Production system and method of fuel ethanol

A technology of fuel ethanol and mixed materials, applied in biofuels, methods of supporting/immobilizing microorganisms, methods of sterilization, etc., can solve the problems of decreased pervaporation performance, unrecoverable carbon dioxide, and increased operating costs, etc., to achieve convenient operation, The effect of high added value of products and low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

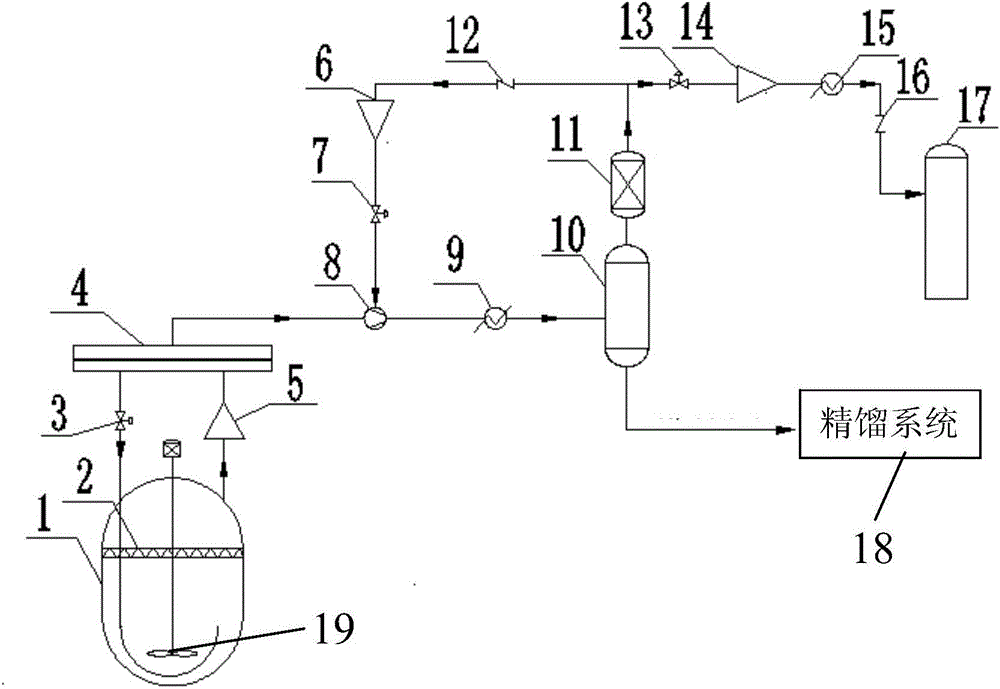

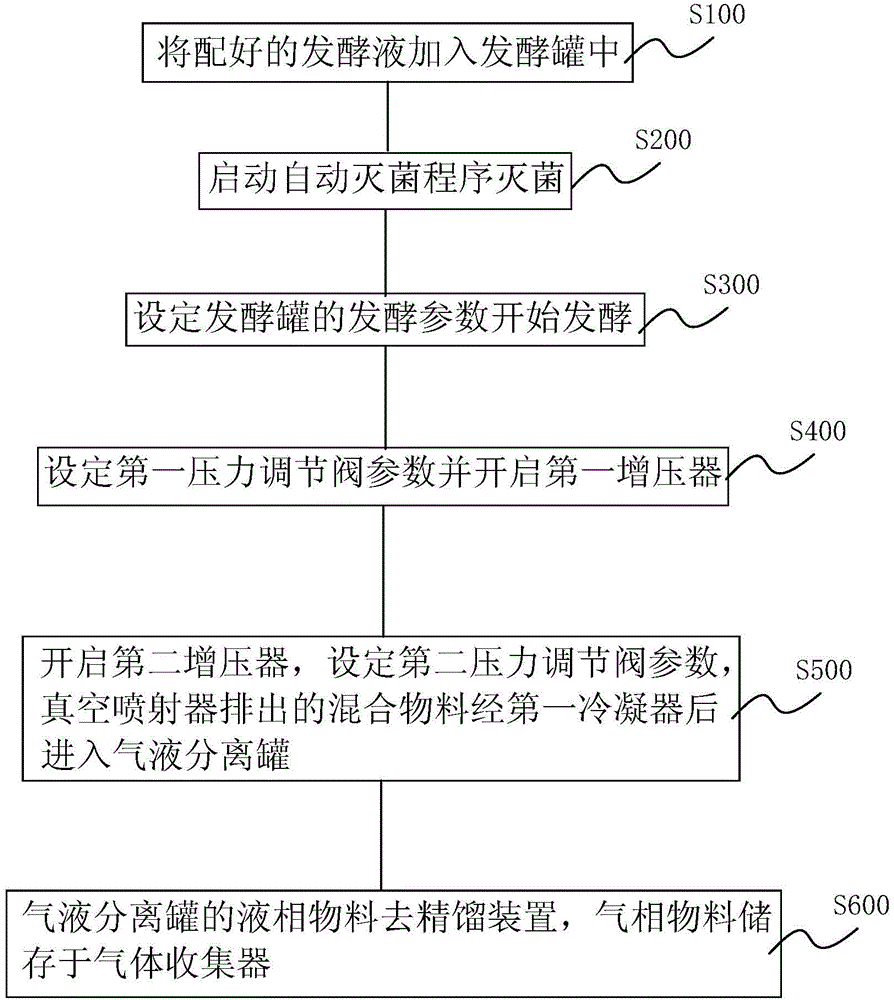

[0074] The effective membrane area of the membrane separation device is 4.0m 2 , add the prepared 200L fermentation liquid into the fermenter 1; start the sterilization process, the sterilization temperature is 120°C, and the sterilization time is 30min; After the temperature of the fermenter 1 is constant, weigh 800g Angel dry yeast, after rehydration and activation for 20min, put it into the fermenter 1 to start fermentation; ferment for 15h, set the pressure of the first pressure regulating valve 3 to 0.15MPa, and start the second A supercharger 5, when the bottom of the fermenter 1 has bubbles evenly blowing out, continue for 10 minutes; open the second supercharger 6, set the pressure of the second pressure regulating valve 7 to 0.4MPa, and the mixed material discharged by the vacuum ejector 8 Enter the gas-liquid separation tank 10 after passing through the first condenser 9; set the pressure of the third pressure regulating valve 13 to 0.2 MPa, start the third superch...

Embodiment 2

[0076] The effective membrane area of the membrane separation device is 6.0m 2 , add the prepared 300L fermentation liquid into the fermenter 1; start the sterilization process, the sterilization temperature is 110°C, and the sterilization time is 45min; ; After the temperature of the fermenter 1 is constant, weigh 1.0kg of Angel yeast, after rehydration and activation for 30 minutes, put it into the fermenter 1 to start fermentation; after 15 hours of fermentation, start to add the feed solution with a glucose concentration of 800g / L, set the first The pressure of the pressure regulating valve 3 is 0.3MPa, and the first supercharger 5 is started. When there are bubbles evenly blowing out from the bottom of the fermenter 1, it lasts for 5 minutes; the second supercharger 6 is started, and the second pressure regulating valve 7 is set. The pressure is 0.5MPa, and the mixed material discharged from the vacuum ejector 8 enters the gas-liquid separation tank 10 after passing thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com