Vapor deposition device

A technology of vapor phase deposition and reaction chamber, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of limiting the range of reactant selection, reduce the difficulty of operation and the required cost, and be easy to implement , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

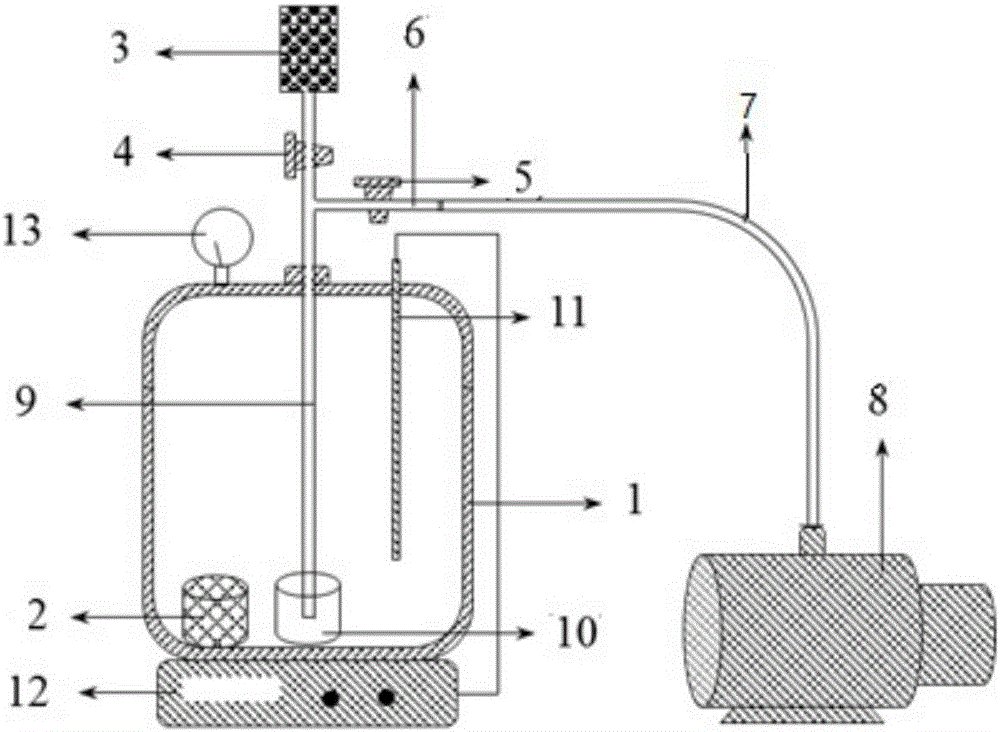

[0027] A vapor deposition apparatus, such as figure 1 As shown, it includes a reaction chamber 1 , a reactant injection component, a vacuum decompression component and a temperature control component, and both the reactant injection component and the vacuum decompression component are in communication with the reaction chamber 1 . The material of the reaction chamber is metal

[0028] Wherein, the reactant injection assembly includes a reactant holding chamber 3, a gasification container 10, a liquid injection pipe 9 and a liquid injection valve 4 arranged on the liquid injection pipe 9, and the reactant containing chamber 3 and the liquid injection valve) are arranged in the reaction chamber Outside the body 1, the gasification container 10 is located inside the reaction chamber 1. One end of the liquid injection pipe 9 is connected to the reactant containing chamber 3, and the other end extends into the reaction chamber 1 and is arranged correspondingly to the gasification c...

Embodiment 2

[0033] This embodiment is basically the same as Embodiment 1, the difference is that one end of the vacuum tube 6 of this embodiment is connected to the vacuum pump 8, and the other end is directly connected to the reaction chamber 1, and the material of the reaction chamber 1 can be glass, quartz or plastic One of.

[0034] The vapor deposition device of this embodiment can realize the controllable progress of the vapor deposition reaction by changing the vacuum degree (pressure) and temperature of the reaction. The invention has simple steps and is easy to implement, and the device is small and portable, can be used as a reaction device for vapor deposition reaction, has a simple structure and low cost, and is suitable for large-scale commercial application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com