2.5-dimensional carbon fiber/aramid fiber woven perform reinforced cashew nut shell oil modified phenolic resin-based friction material

A kind of aramid fiber, friction material technology, applied in the direction of friction lining, mechanical equipment, gear transmission mechanism, etc., can solve the problems of poor structural integrity of friction material, difficult to bear large torsional moment, easy to delaminate and damage, etc. Insulation and anti-aging properties, improved impact resistance, less cracking and peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

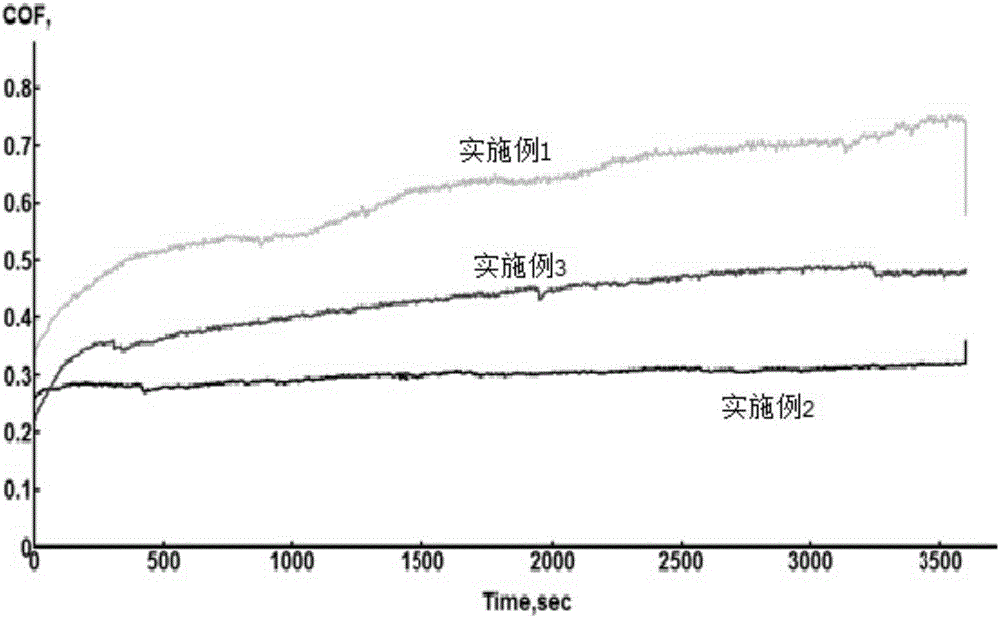

Embodiment 1

[0025] A 2.5-dimensional carbon fiber / aramid fiber woven preform reinforced modified cashew nut shell oil phenolic resin-based friction material, the preparation method of the friction material comprises the following steps:

[0026] (1) Preparation of 2.5-dimensional carbon fiber / aramid fiber woven preform:

[0027] First, the carbon fiber and the aramid fiber are parallel twisted to make a ply yarn, which is used as a weft yarn (80 pieces / 10cm), and the carbon fiber is used as a warp yarn (80 pieces / 10cm); Each layer is a carbon fiber woven prefabricated body (thickness 2mm) woven into a deep cross-linked structure; the volume content of carbon fiber is 20%, and the volume content of aramid fiber is 35%; the number of weft yarn layers is 2 layers; carbon fiber / aramid fiber prefabrication The bulk density is 1.4 / cm 3 .

[0028] Both the carbon fiber and the aramid fiber are 800tex; the carbon fiber is a pre-oxidized polyacrylonitrile-based carbon fiber.

[0029] (2) Prepar...

Embodiment 2

[0035] A 2.5-dimensional carbon fiber / aramid fiber woven preform reinforced modified cashew nut shell oil phenolic resin-based friction material, the preparation method of the friction material comprises the following steps:

[0036] (1) Preparation of 2.5-dimensional carbon fiber / aramid fiber woven preform:

[0037] First, the carbon fiber and the aramid fiber are parallel twisted to make a ply yarn, which is used as a weft yarn (144 pieces / 10cm), and the carbon fiber is used as a warp yarn (20 pieces / 10cm); Each layer is a carbon fiber woven prefabricated body (thickness 4mm) woven into a deep cross-linked structure; the volume content of carbon fiber is 20%, and the volume content of aramid fiber is 55%; the number of weft yarn layers is 4 layers; carbon fiber / aramid fiber prefabrication The bulk density is 1.6g / cm 3 .

[0038] The carbon fiber has been pretreated before use, and the pretreatment method is: use nitric acid solution to carry out liquid phase oxidation surf...

Embodiment 3

[0045] A 2.5-dimensional carbon fiber / aramid fiber woven preform reinforced modified cashew nut shell oil phenolic resin-based friction material, the preparation method of the friction material comprises the following steps:

[0046] (1) Preparation of 2.5-dimensional carbon fiber / aramid fiber woven preform:

[0047] First, the carbon fiber and the aramid fiber are twisted to make a ply yarn, which is used as a weft yarn (200 pieces / 10cm), and the carbon fiber is used as a warp yarn (20 pieces / 10cm); Each layer is a carbon fiber woven prefabricated body (thickness 12mm) woven into a deep cross-linked structure; the volume content of carbon fiber is 20%, and the volume content of aramid fiber is 75%; the number of weft yarn layers is 6 layers; carbon fiber / aramid fiber prefabrication The bulk density is 2.5g / cm 3 .

[0048] The carbon fiber has been pretreated before use, and the pretreatment method is: use nitric acid solution to carry out liquid phase oxidation surface trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com