Recipe function module integrating product batch operation, monitoring and maintenance

A technology of functional modules and recipes, which is applied in the field of recipe functional modules, can solve problems such as changes, few, and immature control technologies, and achieve the effects of reducing time and engineering costs, facilitating modification, and reducing fault repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

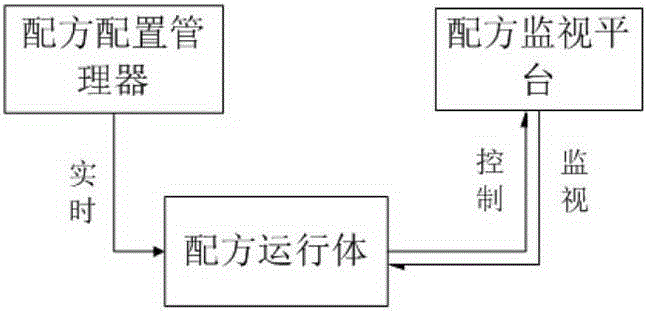

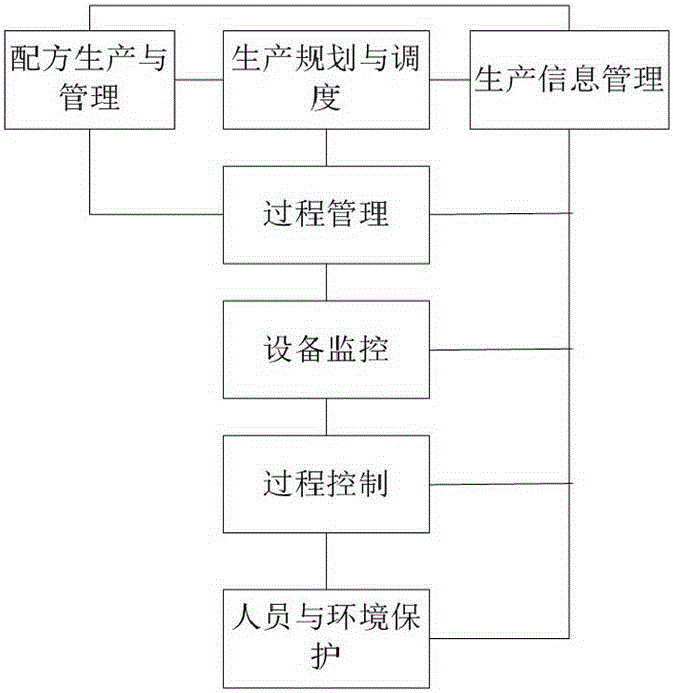

[0032] The present invention provides a recipe function module for automated batch production based on a distributed control system DCS, which supports a modular production batch design method by determining its physical and process information and their sequence Establish the production batch process, mainly responsible for the functions of formula product batch operation, monitoring, maintenance, etc., widely used in fine chemicals, new materials, pharmaceuticals and other fields. The formula function module of the invention can be used in combination with man-machine interface, algorithm and database functions to manage formula and process control.

[0033] For the fine chemical industry that uses a large number of compounding technology to process products, due to the particularity of the application object, it is difficult to use a single compound t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com