High malleability thin film, preparation method for same and application of preparation method

A ductile and thin film technology, which is applied in the field of high ductile film and its preparation, can solve the problems of poor reliability and high research and development costs, and achieve the effects of high production efficiency, low cost and improved ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

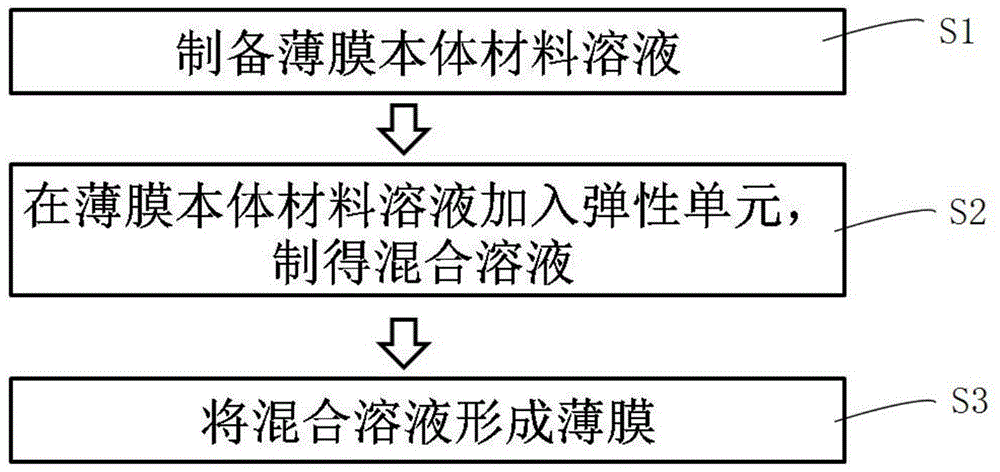

Method used

Image

Examples

Embodiment 1

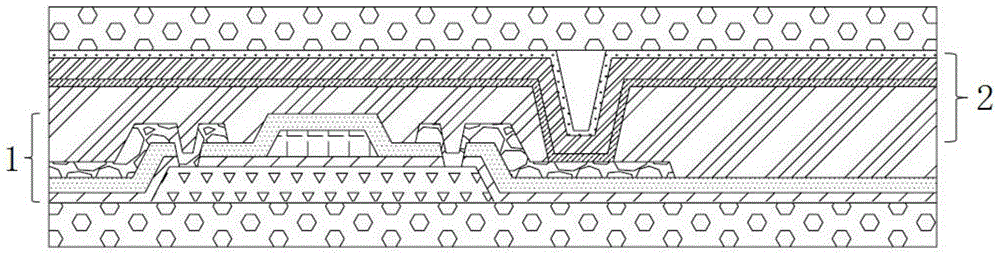

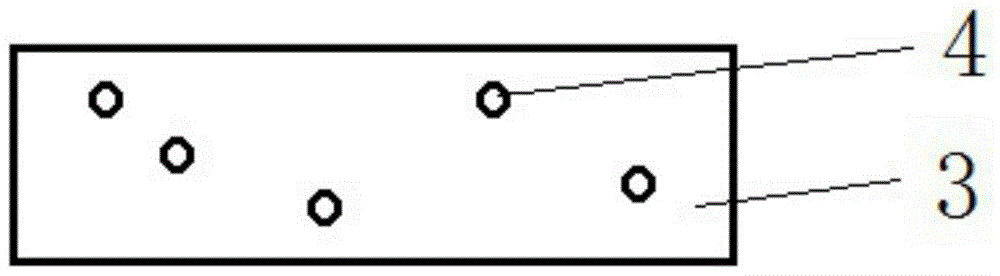

[0036] This embodiment provides a film with high ductility, such as Figure 3a As shown, it includes a film body 3 and an elastic unit 4 disposed in the film body 3 .

[0037] As an embodiment of the present invention, the film body 3 in this embodiment is IGZO (English full name is IndiumGalliumZincOxide, translated as Indium Gallium Zinc Oxide), the thickness is 50nm; the elastic unit 4 is EDOT (3,4-ethylenedioxythiophene ) particles with a particle size of 5 nm. The electrical conductivity of the film body 3 and the elastic unit 4 is the same, and the volume content of the elastic unit 4 in the film body 3 is 5%.

[0038] As a changeable embodiment of the present invention, the types of materials of the film body 3 and the elastic unit 4 are not limited thereto, and both achieve the purpose of the present invention and belong to the protection scope of the present invention.

[0039] As an embodiment of the present invention, in this embodiment, the elastic deformation of...

Embodiment 2

[0052] This embodiment provides a film with high ductility, including a film body and an elastic unit disposed in the film body.

[0053] As an embodiment of the present invention, in this embodiment, the film body is ZnO with a thickness of 400 nm, and the elastic unit is polythiophene with a thickness of 10 nm. The conductivity of the film body and the elastic unit are the same. The content of the elastic unit in the film body is 6%.

[0054] As an embodiment of the present invention, the elastic deformation of the elastic unit is 30%; the elastic unit is a spring, and the length and diameter are 30nm×20nm.

[0055] When the film with high ductility is deformed by an external force, the elastic unit deforms before the film body, and can bear or absorb most of the strain, so that the film body does not deform too much, effectively avoiding the deformation of the film. Mechanical failure, and then any curling of the film is achieved.

[0056] At the same time, the conductivit...

Embodiment 3

[0064] This embodiment provides a film with high ductility, including a film body and an elastic unit disposed in the film body.

[0065] As an embodiment of the present invention, in this embodiment, the film body is an Ag film with a thickness of 100 nm, and the elastic unit is a polyaniline spring with a thickness of 5 nm. The conductivity of the film body and the elastic unit are the same. The content of the elastic unit in the film body is 4%.

[0066] As an embodiment of the present invention, the elastic deformation of the elastic unit is 30%; the elastic unit is a spring, and the length and diameter are 35nm×20nm.

[0067] When the film with high ductility is deformed by an external force, the elastic unit deforms before the film body, and can bear or absorb most of the strain, so that the film body does not deform too much, effectively avoiding the deformation of the film. Mechanical failure, and then any curling of the film is achieved.

[0068] At the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com