Maca extract as well as preparation method and application thereof

A technology of maca extract and crude extract, which is applied in the direction of drug combination, medical formula, plant raw materials, etc., can solve the problems of many impurities, incomplete extraction, low absorption rate, etc., and achieve simple process, low price, and enhanced energy The effect of metabolic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

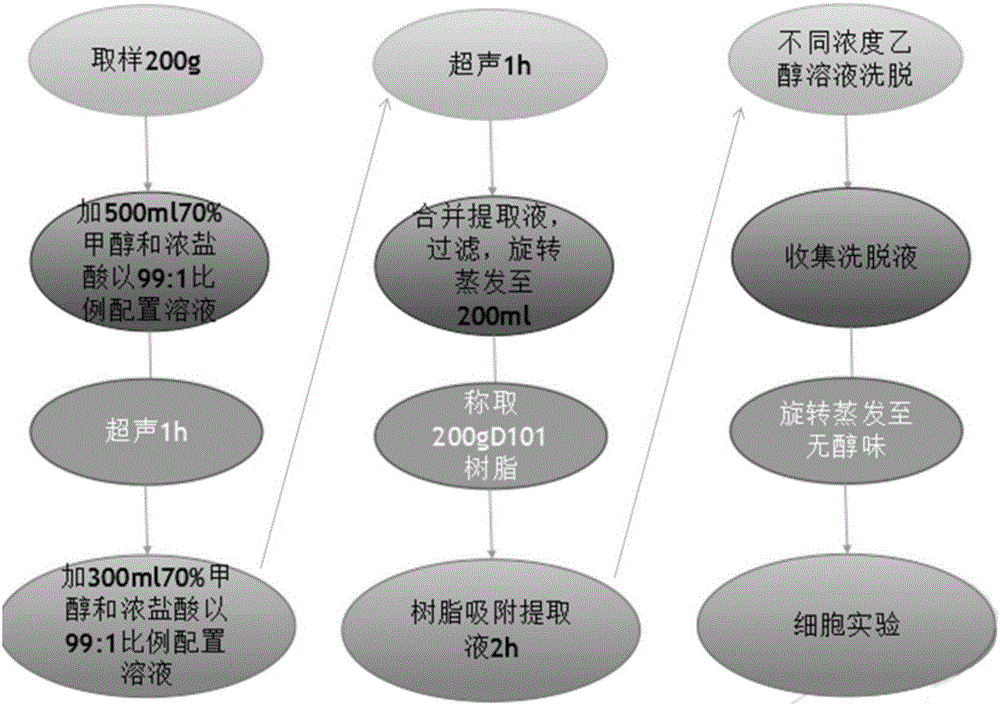

[0027] 1. Preparation of maca extract

[0028] 200 grams of Maca samples are washed, drained and ground into powder; 70% methanol and concentrated hydrochloric acid are used to configure the extract in a ratio of 99:1, wherein hydrochloric acid can make the pigment in Maca appear red, which is beneficial to the next step Chromatography; add the above-mentioned extract in two times, add 500 ml for the first time, add 300 ml for the second time, extract with ultrasonic (300w, SB5200D) for about 1 hour after adding each time, and obtain the crude extract; The liquid was concentrated by rotary evaporation to no alcohol smell (about 200 ml) to obtain a concentrated crude extract; 200 grams of D101 macroporous resin (column volume about 200 ml) was weighed, and the concentrated crude extract obtained in step 3 was passed through the column, Adsorb for about 2 hours; elute the above macroporous resin in the order of one column volume of water, three column volumes of 20% ethanol, fou...

Embodiment 2

[0035] The preparation method of Maca extract comprises the following steps:

[0036] Step 1. Wash 200 grams of Maca, drain and make powder;

[0037] Step 2. Prepare the extract with 40% methanol and concentrated hydrochloric acid at a ratio of 98:2, add the extract twice, add 500 ml for the first time, add 500 ml for the second time, and extract about In 40 minutes, the crude extract was obtained;

[0038] Step 3. Concentrate the crude extract in step 2 by rotary evaporation until it has no alcohol smell (about 200 ml) to obtain a concentrated crude extract;

[0039] Step 4. Weigh 200 grams of D101 macroporous resin (column volume about 200 milliliters), pass the concentrated crude extract obtained in step 3 through the column, and absorb for about 2 hours;

[0040] Step 5, elute the macroporous resin in the order of one column volume of water, three column volumes of 20% ethanol, four column volumes of 50% ethanol, three column volumes of 75% ethanol, and one column volume...

Embodiment 3

[0043] The preparation method of Maca extract comprises the following steps:

[0044] Step 1. Wash 100 grams of Maca, drain and make powder;

[0045] Step 2, prepare the extract with 50% methanol and concentrated hydrochloric acid at a ratio of 99.5:0.5, add the extract twice, add 250 ml for the first time, add 250 ml for the second time, use ultrasonic extraction after each addition 50 minutes to obtain the crude extract;

[0046] Step 3. Concentrate the crude extract in step 2 by rotary evaporation until it has no alcohol smell (about 100 ml) to obtain a concentrated crude extract;

[0047] Step 4. Weigh 100 grams of D101 macroporous resin (column volume about 100 milliliters), pass the concentrated crude extract obtained in step 3 through the column, and absorb for about 2 hours;

[0048] Step 5, elute the macroporous resin in the order of one column volume of water, three column volumes of 20% ethanol, four column volumes of 50% ethanol, three column volumes of 75% ethanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com