A mosaic type pt@ceo 2 Preparation method of nanotube composite catalyst

A nanotube composite and catalyst technology is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., to achieve the effect of improving thermal stability and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

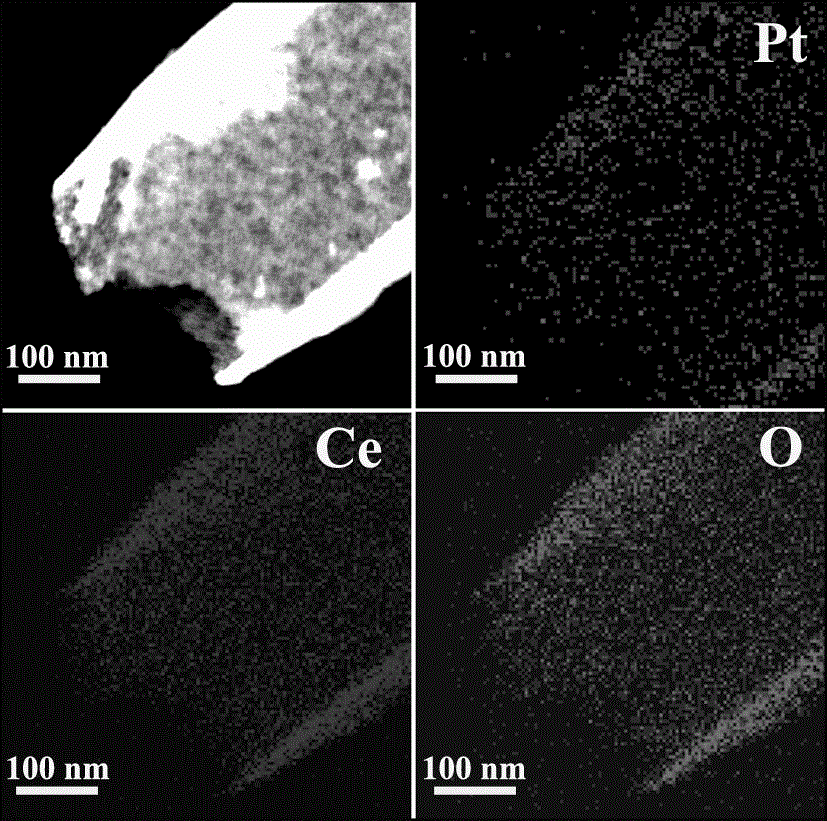

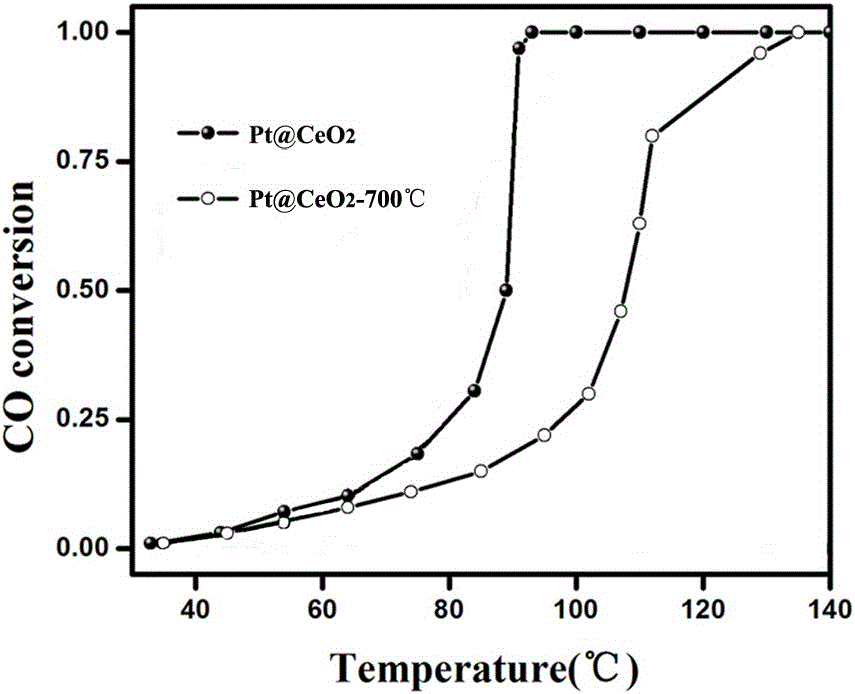

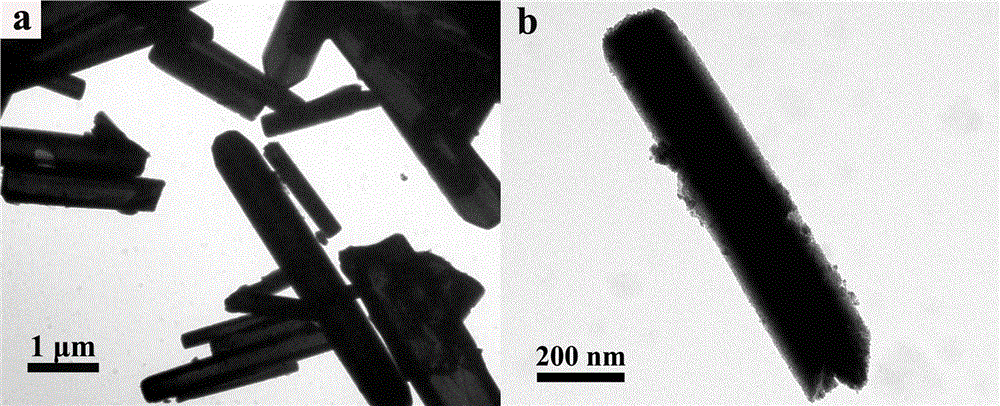

[0027] Mosaic Pt@CeO 2 Preparation method of nanotube composite catalyst

[0028] Take 6.95 g Ce(NO 3 ) 3 ·6H 2 O and 5.77 g of urea were dissolved in 320 ml of deionized water, stirred for 10 min, then transferred to a three-neck flask, and kept in an oil bath at 80°C for 24 hours; cooled, washed with deionized water several times, and dried at 80°C to obtain rod-shaped Ce(OH)CO 3 Precursor.

[0029] Dissolve 3.6 g of NaOH in 30 ml of deionized water after vacuum deoxygenation, and then add 100 mg of the above-mentioned dried Ce(OH)CO 3 Stir the precursor, then evacuate, blow nitrogen to remove oxygen; under nitrogen atmosphere, add 1 ml prepared 0.02 mol / L H 2 PtCl 6 Solution, stirred at a slow speed (300rpm) for 1 day, and stood still for 2 days; centrifuged, washed with deionized water several times, and dried at 80°C;

[0030] Disperse the above dried sample in 10 ml deionized water, add 5 ml HNO 3 (1 mol / L), shake gently for 30-60 minutes, then centrifuge, wash ...

Embodiment 2

[0033] Mosaic Pt@CeO 2 Preparation method of nanotube composite catalyst: influence of stirring speed on final product morphology

[0034] Take 6.95 g Ce(NO 3 ) 3 ·6H2 O and 5.77 g of urea were dissolved in 320 ml of deionized water, stirred for 10 min, then transferred to a three-neck flask, and kept in an oil bath at 80°C for 24 hours; cooled, washed with deionized water several times, and dried at 80°C to obtain rod-shaped Ce(OH)CO 3 Precursor.

[0035] Dissolve 3.6 g of NaOH in 30 ml of deionized water after vacuum deoxygenation, and then add 100 mg of the above-mentioned dried Ce(OH)CO 3 Stir the precursor, then evacuate, blow nitrogen to remove oxygen; under nitrogen atmosphere, add 1 ml prepared 0.02 mol / L H 2 PtCl 6 Solution, stirred rapidly (900rpm) for 1 day, and stood still for 2 days; centrifuged, washed with deionized water several times, and dried at 80°C;

[0036] Disperse the above dried sample in 10 ml deionized water, add 5 ml HNO 3 (1 mol / L), shake g...

Embodiment 3

[0039] Mosaic Pt@CeO 2 Preparation method of nanotube composite catalyst: influence of reaction time on final product morphology

[0040] Take 6.95 g Ce(NO 3 ) 3 ·6H 2 O and 5.77 g of urea were dissolved in 320 ml of deionized water, stirred for 10 min, then transferred to a three-neck flask, and kept in an oil bath at 80°C for 24 hours; cooled, washed with deionized water several times, and dried at 80°C to obtain rod-shaped Ce(OH)CO 3 Precursor.

[0041] Dissolve 3.6 g of NaOH in 30 ml of deionized water after vacuum deoxygenation, and then add 100 mg of the above-mentioned dried Ce(OH)CO 3 Stir the precursor, then evacuate, blow nitrogen to remove oxygen; under nitrogen atmosphere, add 1 ml prepared 0.02 mol / L H 2 PtCl 6 Solution, stirred at a slow speed (300rpm) for 1 day, and stood still for 3 days; centrifuged, washed with deionized water several times, and dried at 80°C;

[0042] Disperse the above dried sample in 10 ml deionized water, add 5 ml HNO 3 (1 mol / L)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com