A kind of personalized 3D printing insole and its manufacturing method

A technology of 3D printing and manufacturing method, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problem of not being able to individually adjust the properties of local materials on the sole of the foot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 (flat foot children)

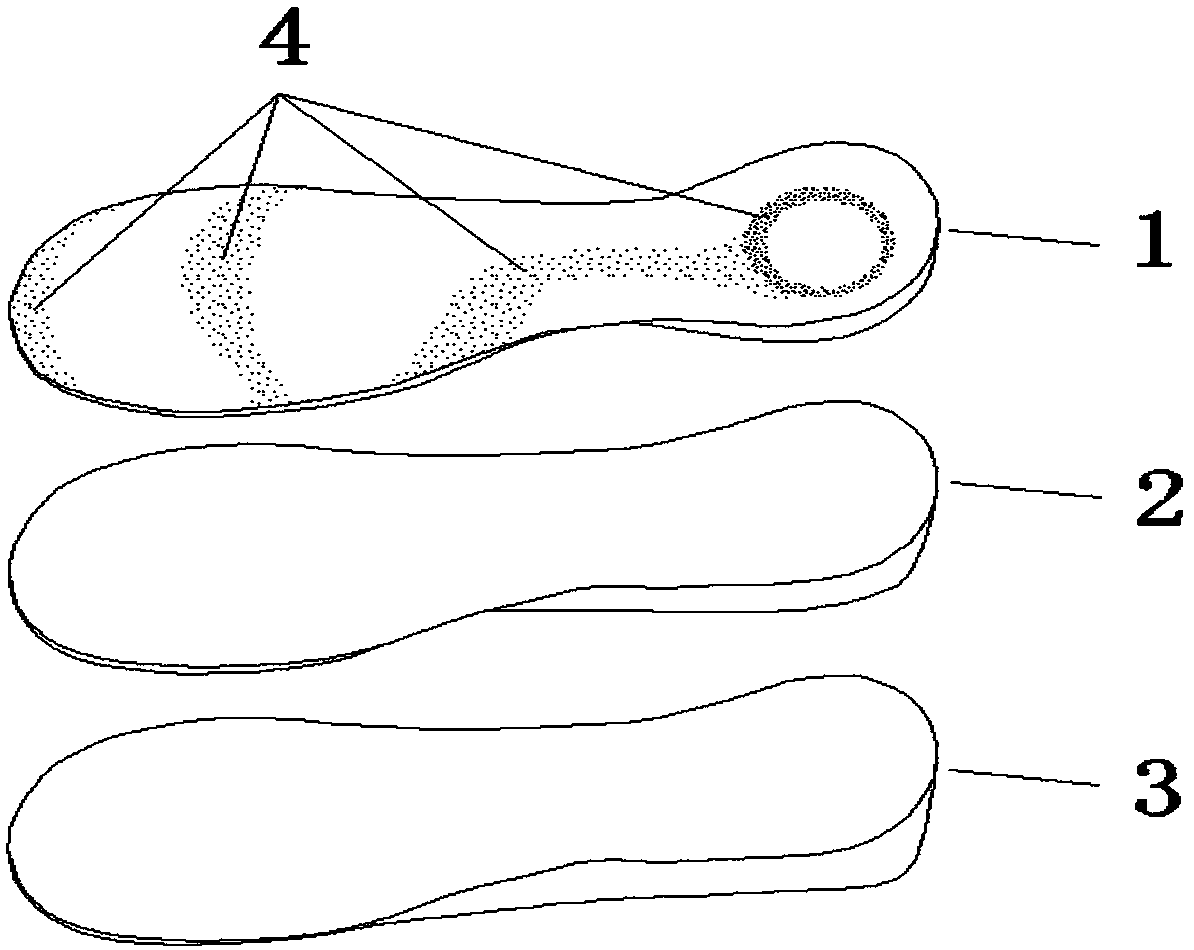

[0050] A personalized custom 3D insole and a manufacturing method thereof, comprising:

[0051] (1) First let a child with flat feet stand on one foot, bend the other lower limb to lift up, lower the calf vertically, use a slightly harder plate to keep the sole of the foot up horizontally, and prepare the mobile phone camera to be located at five angles on the front and slope of the child's sole , each time the plate is opened to take a quick photo; enter the child's weight G (kg), foot length L (mm) and width W (mm) through the software, collect basic data on the sole of the foot, and analyze the data to establish a three-dimensional foot model;

[0052] Divide the sole of the foot into 11 regions: T1 first phalanx, Ta second to fifth phalanx, M1 first metatarsal, M2 second metatarsal, M3 third metatarsal, M4 fourth metatarsal, M5 fifth metatarsal, MFI foot arch Medial, MFO outer arch, HI heel inner, HO heel outer; perform reference...

Embodiment 2

[0063] Embodiment 2 (fall-proof old man)

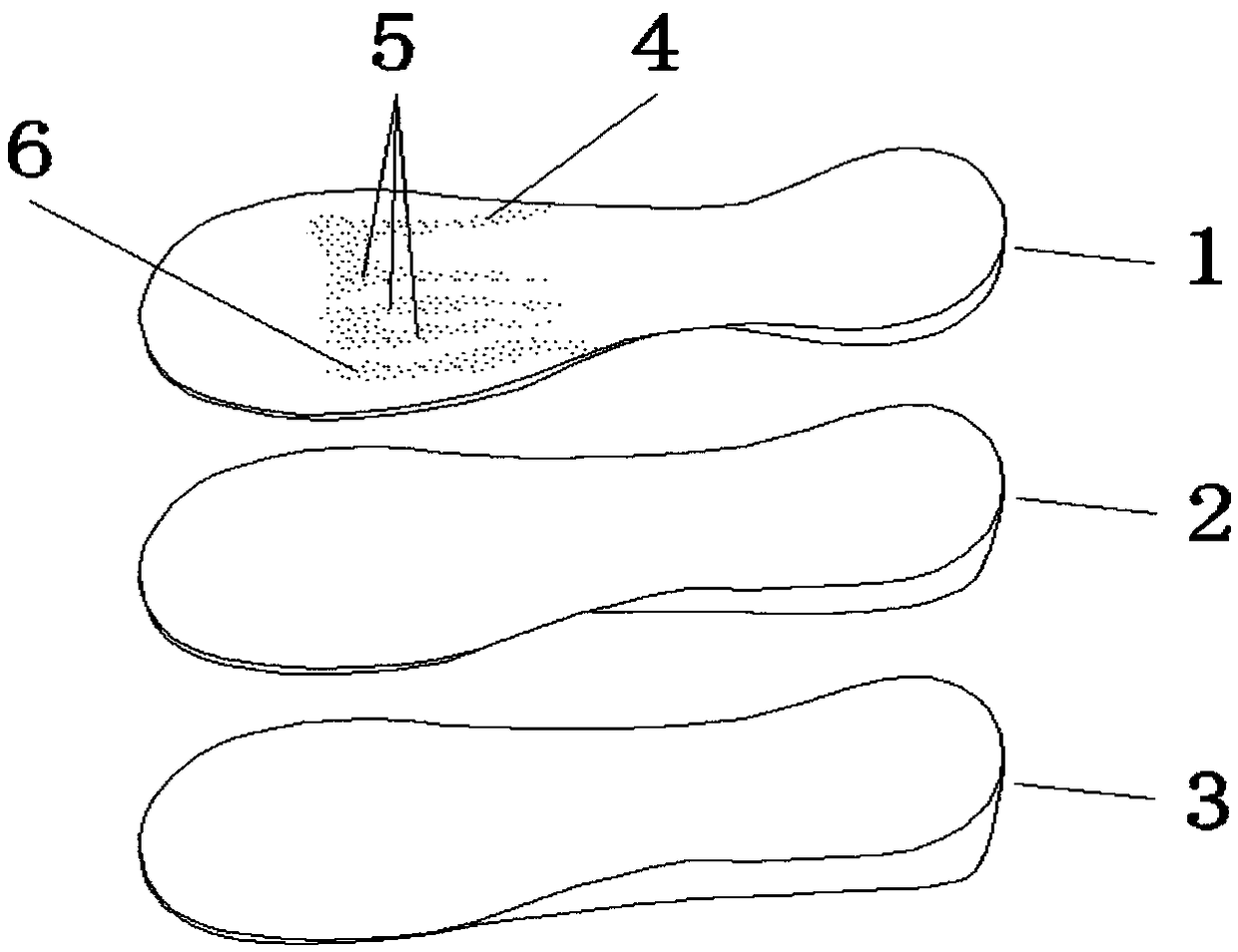

[0064] A personalized custom 3D insole and a manufacturing method thereof, comprising:

[0065] (1) First let an old man stand on one foot, bend the other lower limb to lift up, lower the lower leg vertically, use a slightly harder plate to keep the sole of the foot up horizontally, and prepare the mobile phone camera to be located at five angles on the front and slope of the sole of the foot. Quickly take pictures by pulling out the plate once; enter the old man's weight G (kg), foot length L (mm) and width W (mm) through the software, and analyze the data to establish a three-dimensional foot model;

[0066] Divide the sole of the foot into 11 regions: T1 first phalanx, Ta second to fifth phalanx, M1 first metatarsal, M2 second metatarsal, M3 third metatarsal, M4 fourth metatarsal, M5 fifth metatarsal, MFI foot arch Medial, MFO lateral arch, HI medial heel, HO lateral heel. Carry out reference calculation for each district accordi...

Embodiment 3

[0077] Embodiment 3 (diabetes patient)

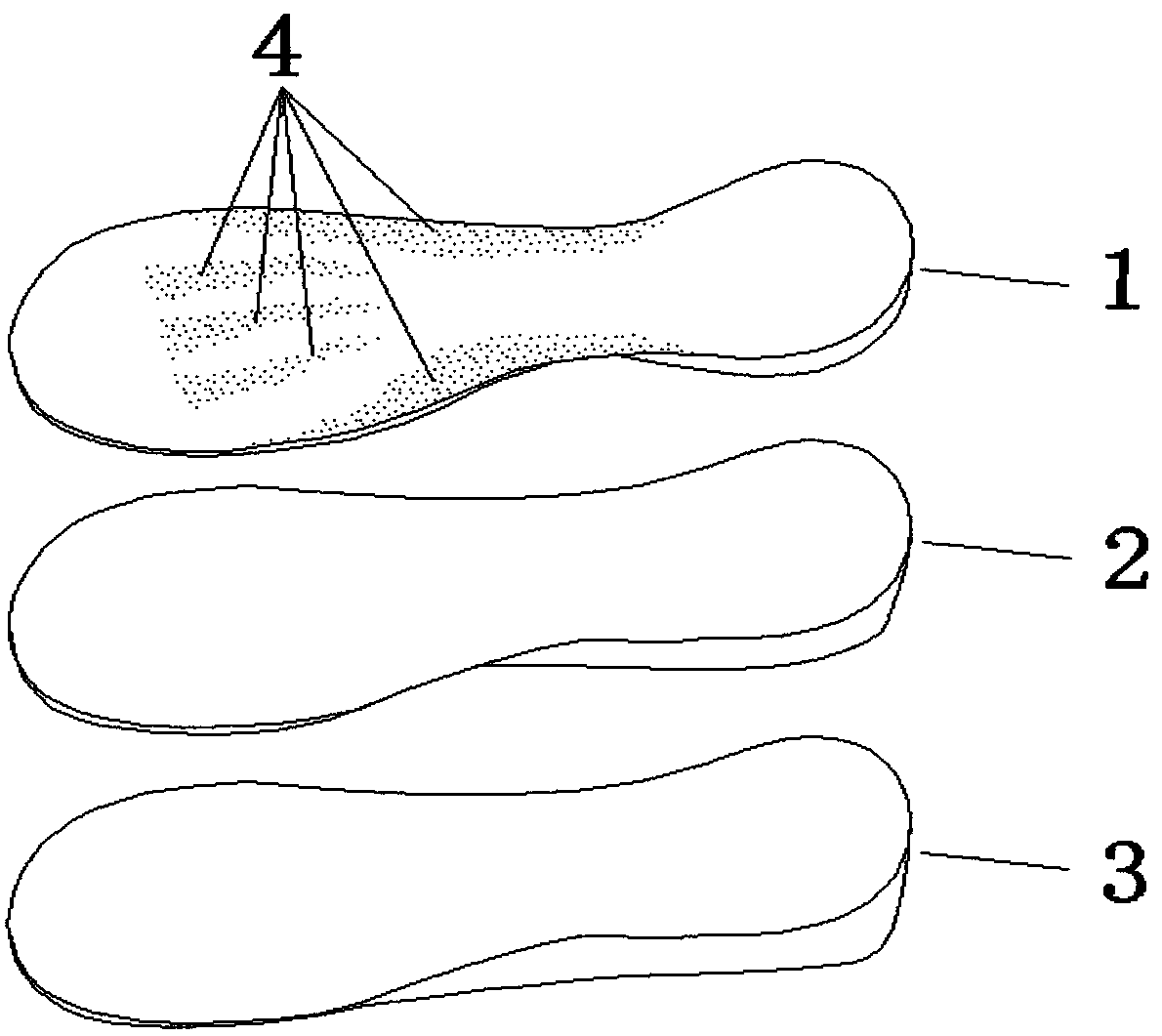

[0078] A personalized custom 3D insole and a manufacturing method thereof, comprising:

[0079] (1) First let a diabetic stand on one foot, bend the other lower limb and raise the lower leg vertically, use a slightly harder plate to keep the sole of the foot up horizontally, and prepare the mobile phone camera to be located at five angles on the front and slope of the sole of the foot. Quickly take pictures every time you open the plate; input the weight G (kg), sole length L (mm) and width W (mm) of the diabetic patient through the software, and analyze the data to establish a three-dimensional foot model;

[0080]Divide the sole of the foot into 11 regions: T1 first phalanx, Ta second to fifth phalanx, M1 first metatarsal, M2 second metatarsal, M3 third metatarsal, M4 fourth metatarsal, M5 fifth metatarsal, MFI foot arch Medial, MFO outer arch, HI heel inner, HO heel outer; perform reference calculation for each area according to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com