Resource utilization method of high-salinity organic wastewater formed in light stabilizer 944 production

A light stabilizer and organic wastewater technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as incomplete oxidation, harmful by-products, and low reaction rate , to achieve the effect of small secondary pollution, small footprint and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

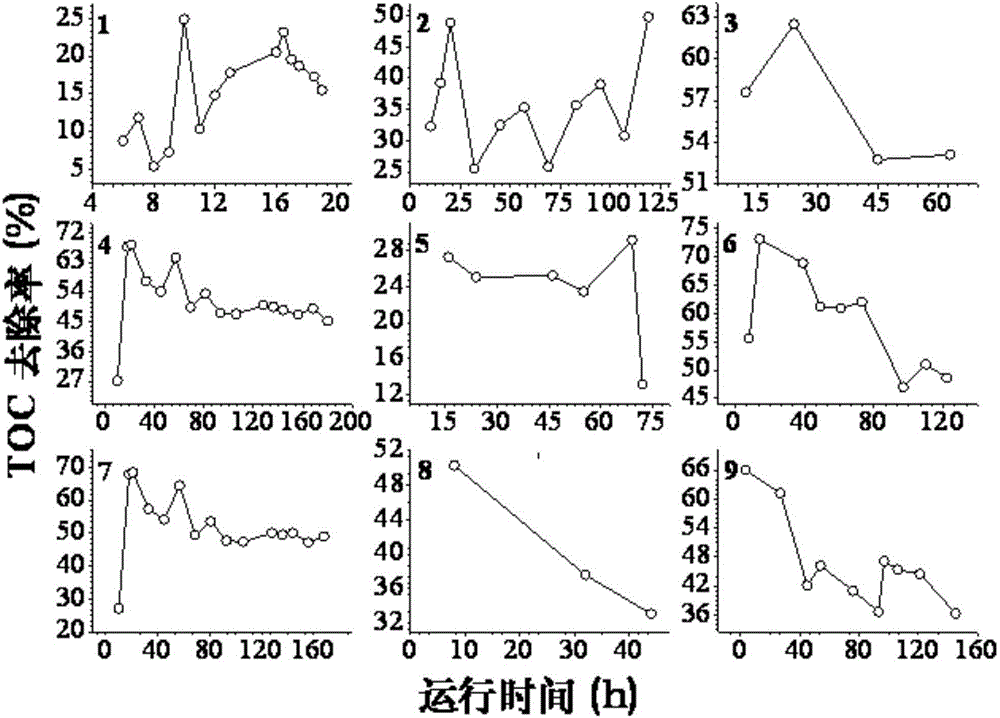

Embodiment 1

[0033] Use a pump to transport the high-salt organic wastewater formed by the production of light stabilizer 944 into the reactor from the bottom of the reactor. There is a catalyst bed in the reactor, and a gas distributor is installed at the lower part of the catalyst bed; after passing the air through the ozone generator, Then enter the catalyst bed through the gas distributor at the bottom of the reactor, the organic matter in the wastewater and ozone undergo an oxidation reaction on the catalyst surface in the reactor, and the macromolecular organic matter insoluble in water in the high-salt wastewater is oxidized into water-soluble organic matter; The final effluent flows out from the upper part of the reactor; the reaction temperature in the catalytic ozonation reactor is room temperature, the reaction pressure is normal pressure, the gas-water ratio is 70, the ozone concentration is 70mg / L, and the catalyst amount of 1.0wt.% Mn / activated carbon is 50mL , the waste water...

Embodiment 2

[0035] Use a pump to transport the high-salt organic wastewater formed by the production of light stabilizer 944 into the reactor from the bottom of the reactor. There is a catalyst bed in the reactor, and a gas distributor is installed at the lower part of the catalyst bed; after passing the air through the ozone generator, Then enter the catalyst bed through the gas distributor at the bottom of the reactor, the organic matter in the wastewater and ozone undergo an oxidation reaction on the catalyst surface in the reactor, and the macromolecular organic matter insoluble in water in the high-salt wastewater is oxidized into water-soluble organic matter; The final effluent flows out from the upper part of the reactor; the reaction temperature in the catalytic ozonation reactor is room temperature, the reaction pressure is normal pressure, the gas-water ratio is 70, the ozone concentration is 80mg / L, and the catalyst amount of 1.2wt.% Fe / molecular sieve is 50mL , the waste water ...

Embodiment 3

[0037] Use a pump to transport the high-salt organic wastewater formed by the production of light stabilizer 944 into the reactor from the bottom of the reactor. There is a catalyst bed in the reactor, and a gas distributor is installed at the lower part of the catalyst bed; after passing the air through the ozone generator, Then enter the catalyst bed through the gas distributor at the bottom of the reactor, the organic matter in the wastewater and ozone undergo an oxidation reaction on the catalyst surface in the reactor, and the macromolecular organic matter insoluble in water in the high-salt wastewater is oxidized into water-soluble organic matter; The final effluent flows out from the upper part of the reactor; the reaction temperature in the catalytic ozonation reactor is room temperature, the reaction pressure is normal pressure, the gas-water ratio is 70, the ozone concentration is 90mg / L, and 2.0wt.% Co / TiO 2 The amount of catalyst is 50mL, and the space velocity of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com