Phosphorus containing small molecule/montmorillonite nano-composite flame retardant flame-retardance epoxy resin composite and preparation method thereof

An epoxy resin and nano-composite technology, which is applied in the field of flame retardancy, can solve the problems of low decomposition temperature and mechanical property damage, and achieve the effects of good thermal stability, high glass transition temperature, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

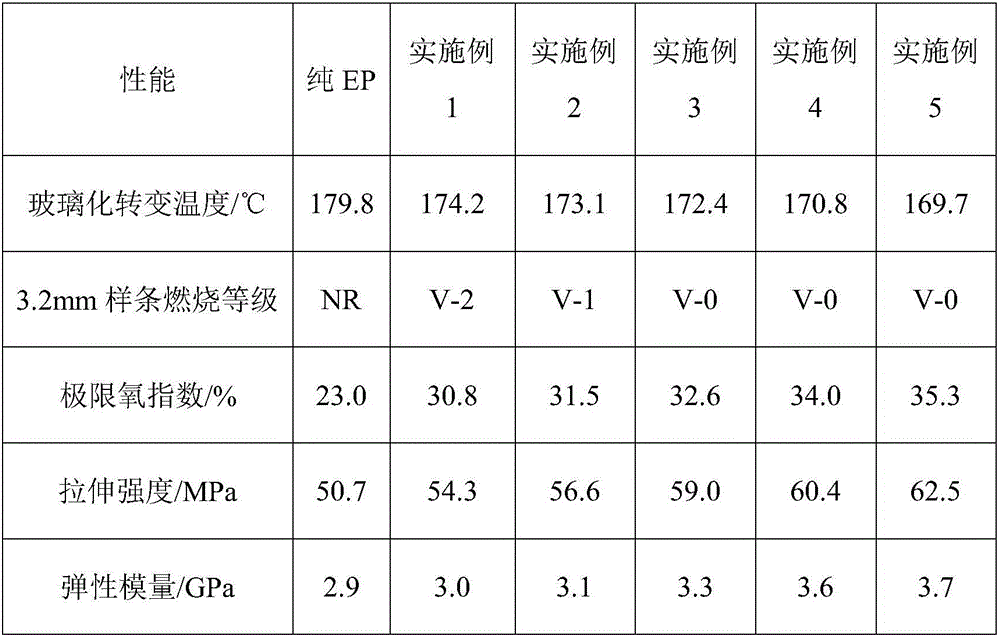

Examples

Embodiment 1

[0030] Phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant flame retardant epoxy resin composition comprising E-44 epoxy resin, curing agent diaminodiphenyl sulfone and phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant , the mass percent of each component is as follows:

[0031] E-44 epoxy resin 74%

[0032] Diaminodiphenylsulfone 22%

[0033] Phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant 4%

[0034] 1) Add the weighed E-44 epoxy resin, phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant into the mixing kettle, raise the temperature to 140°C, and start stirring until the mixed solution is clear;

[0035] 2) Adjust the temperature of the epoxy resin mixture in 1) to 120°C, add the curing agent diaminodiphenylsulfone, and then stir until the curing agent diaminodiphenylsulfone is completely dissolved;

[0036] 3) Vacuumize the epoxy resin mixture...

Embodiment 2

[0039] Phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant flame retardant epoxy resin composition comprising E-44 epoxy resin, curing agent diaminodiphenyl sulfone and phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant , the mass percent of each component is as follows:

[0040] E-44 epoxy resin 72%

[0041] Diaminodiphenylsulfone 22%

[0042] Phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant 6%

[0043] Its preparation method is identical with embodiment 1.

Embodiment 3

[0045] Phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant flame retardant epoxy resin composition comprising E-44 epoxy resin, curing agent diaminodiphenyl sulfone and phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant , the mass percent of each component is as follows:

[0046] E-44 epoxy resin 71%

[0047] Diaminodiphenylsulfone 21%

[0048] Phosphorus-containing small molecule / montmorillonite nanocomposite flame retardant 8%

[0049] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com