Natural mango dye based on mango yellow pigment and preparation method of natural mango dye

A yellow pigment and mango technology, applied in natural dyes, dyeing methods, azo dyes, etc., can solve the problems of low comprehensive utilization rate, environmental hazards, and few applications, and achieve good biodegradability and environmental compatibility. The effect of high dye uptake and high dye content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

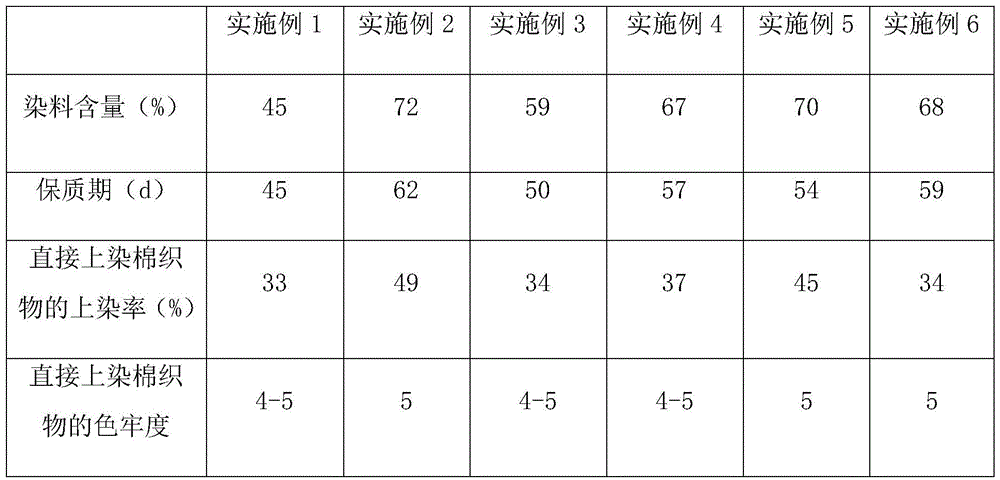

Examples

Embodiment 1

[0027] (1) Clean the fresh and ripe mango, remove the pulp, boil the mango skin in boiling water for 30 seconds to remove the activity of the enzyme, take it out, dry it, and chop it to obtain a volume less than 5mm 3 of crushed mango peel.

[0028] (2) In parts by weight, immerse the pulverized mango peel obtained in 10 parts of step (1) in 100 parts of 80% ethanol aqueous solution, and extract repeatedly 3 times until the extract is colorless, and the extracts are combined and mixed , after 500W ultrasonic treatment for 5min and ultrafiltration membrane filtration, concentrated to obtain a filtrate with a mango yellow pigment content of 49%.

[0029] (3) in parts by weight, add 20 parts of hydrolyzed chitosan, 25 parts of aloe gel and 10 parts of deionized water in the filtrate containing mango yellow pigment prepared by 35 parts of step (2), Stir at 35° C. for 30 minutes at a speed of 500 rpm / min to obtain a natural mango dye based on mango yellow.

Embodiment 2

[0031] (1) Clean the fresh and ripe mango, remove the pulp, boil the mango skin in boiling water for 30 seconds to remove the activity of the enzyme, take it out, dry it, and chop it to obtain a volume less than 5mm 3 of crushed mango peel.

[0032] (2) In parts by weight, immerse the pulverized mango peel obtained in 10 parts of step (1) in 100 parts of 100% ethanol aqueous solution, and extract repeatedly 4 times until the extract is colorless, and the extracts are combined and mixed , after 800W ultrasonic treatment for 10min and ultrafiltration membrane filtration, concentrated to obtain a filtrate with a mango yellow pigment content of 61%.

[0033] (3) by weight, add 30 parts of hydrolyzed chitosan, 30 parts of aloe gel and 30 parts of deionized water in the filtrate containing mango yellow pigment prepared by 50 parts of step (2), Stir at 800 rpm / min for 50 min at 45° C. to obtain a natural mango dye based on mango yellow.

Embodiment 3

[0035] (1) Clean the fresh and ripe mango, remove the pulp, boil the mango skin in boiling water for 30 seconds to remove the activity of the enzyme, take it out, dry it, and chop it to obtain a volume less than 5mm 3 of crushed mango peel.

[0036] (2) In parts by weight, immerse the pulverized mango peel obtained in 10 parts of step (1) in 100 parts of 90% ethanol aqueous solution, and extract repeatedly 3 times until the extract is colorless, and the extracts are combined and mixed , after 600W ultrasonic treatment for 8min and ultrafiltration membrane filtration, concentrated to obtain a filtrate with a mango yellow pigment content of 52%.

[0037] (3) by weight, add 28 parts of hydrolyzed chitosan, 27 parts of aloe gel and 15 parts of deionized water in the filtrate containing mango yellow pigment prepared by 40 parts of steps (2), Stir at 40° C. for 40 minutes at a speed of 700 rpm / min to obtain a natural mango dye based on mango yellow pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com