Preparation method of natural-polymer-based slow-release fertilizer

A natural polymer, slow-release fertilizer technology, applied in the directions of potash fertilizer, phosphate fertilizer, organic fertilizer, etc., can solve the problems of burning seedlings, fertilizers without slow-release properties, improper fertilization, etc., to reduce production costs, improve fruit quality, and promote crops. effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

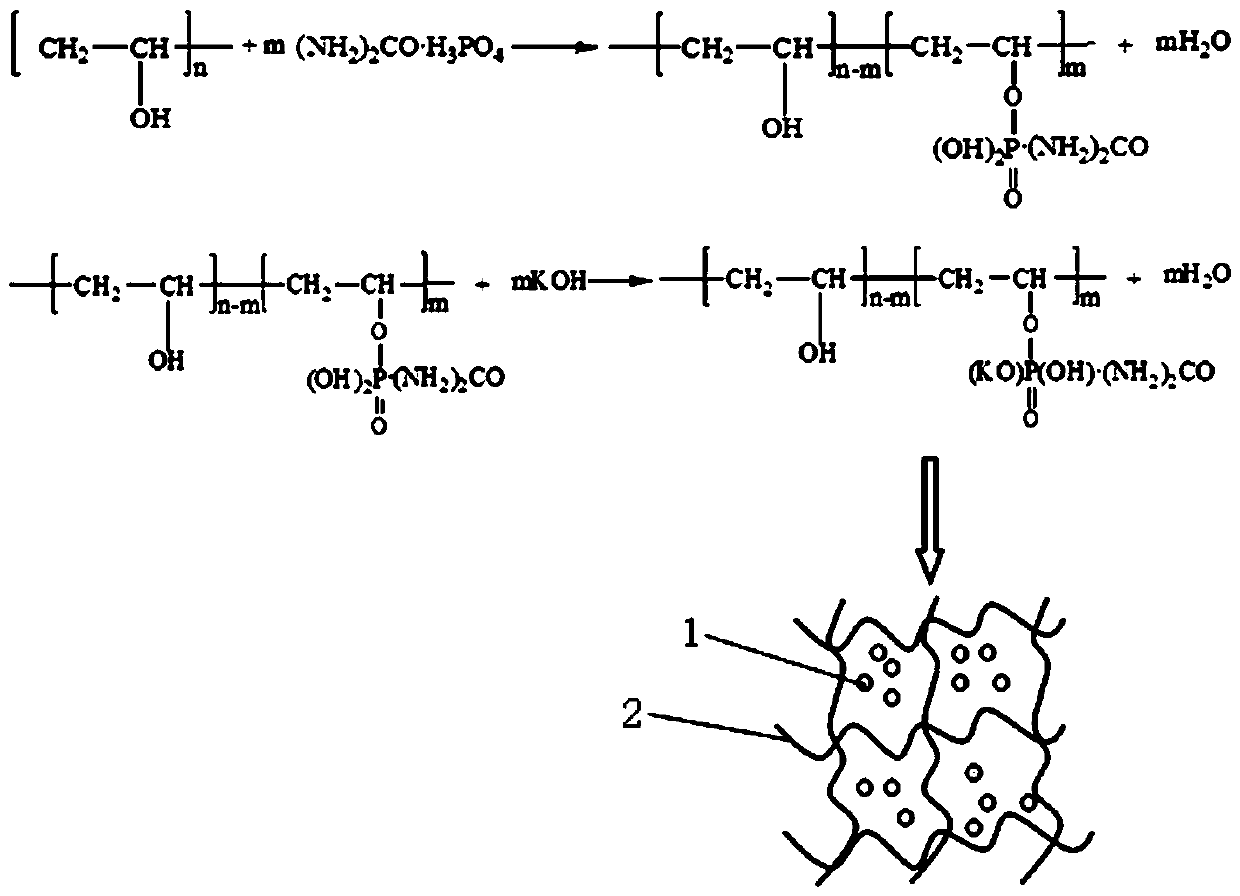

Method used

Image

Examples

Embodiment 1

[0029] Example 1, weigh polyvinyl alcohol, urea phosphate and potassium hydroxide according to the mass ratio of 1:21.35:1.25, and the mass ratio of p-toluenesulfonic acid to urea phosphate is 1.5%.

[0030] The first step is to prepare polymer slow-release liquid fertilizer. Weigh polyvinyl alcohol, add it to a flask, then add distilled water, and stir until the polyvinyl alcohol is dissolved at 90°C; and react for 100-150 minutes; then add potassium hydroxide, and react for 80-100 minutes at 90-100°C. After the reaction, polymer slow-release liquid fertilizer is obtained;

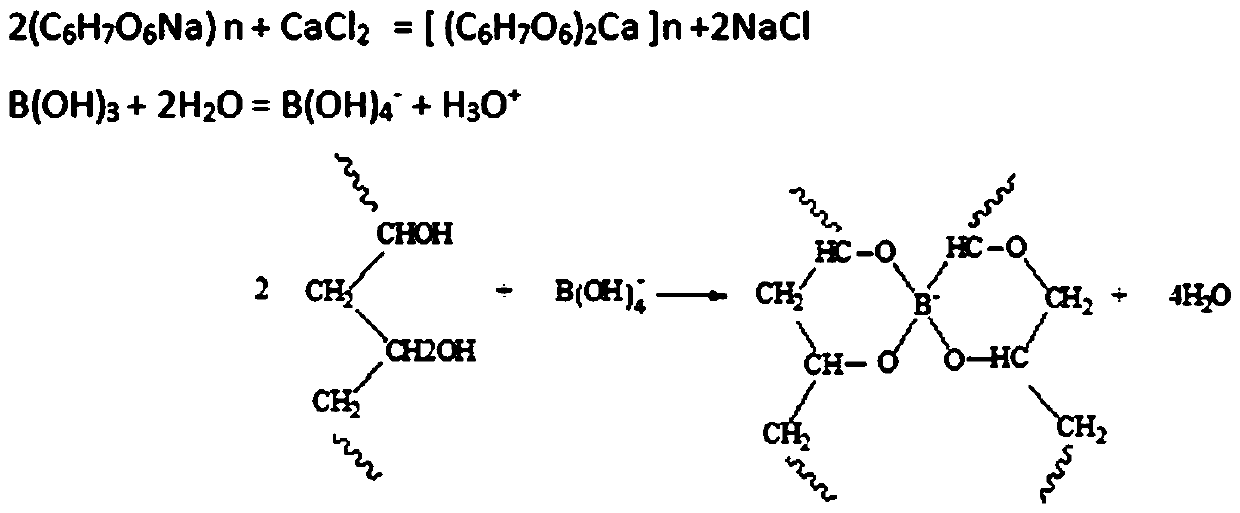

[0031] Second step, prepare 3% borate calcium chloride solution;

[0032] The third step is to mix the polymer slow-release liquid fertilizer and sodium alginate evenly to obtain a mixed solution;

[0033] In the fourth step, the mixed solution obtained in the third step is added dropwise to the 3% calcium chloride borate solution in the second step, and soaked for 30 minutes to obtain a natural polymer-...

Embodiment 2

[0037] Example 2, weigh polyvinyl alcohol, urea phosphate and potassium hydroxide according to the mass ratio of 1:21.35:1.25, and the mass ratio of p-toluenesulfonic acid to urea phosphate is 1.5%.

[0038] The first step is to prepare polymer slow-release liquid fertilizer. Weigh polyvinyl alcohol, add it to a flask, then add distilled water, and stir until the polyvinyl alcohol is dissolved at 90°C; and react for 100-150 minutes; then add potassium hydroxide, and react for 80-100 minutes at 90-100°C. After the reaction, polymer slow-release liquid fertilizer is obtained;

[0039] Second step, prepare 3% borate calcium chloride solution;

[0040] The third step is to mix the polymer slow-release liquid fertilizer and sodium alginate evenly to obtain a mixed solution;

[0041] In the fourth step, the mixed solution obtained in the third step is added dropwise to the 3% calcium chloride borate solution in the second step, and soaked for 40 minutes to obtain a natural polymer-...

Embodiment 3

[0045] In Example 3, polyvinyl alcohol, urea phosphate and potassium hydroxide were weighed according to a mass ratio of 1:21.35:1.25, and the mass ratio of p-toluenesulfonic acid to urea phosphate was 1.5%.

[0046]The first step is to prepare polymer slow-release liquid fertilizer. Weigh polyvinyl alcohol, add it to a flask, then add distilled water, and stir until the polyvinyl alcohol is dissolved at 90°C; and react for 100-150 minutes; then add potassium hydroxide, and react for 80-100 minutes at 90-100°C. After the reaction, polymer slow-release liquid fertilizer is obtained;

[0047] Second step, prepare 3% borate calcium chloride solution;

[0048] The third step is to mix the polymer slow-release liquid fertilizer and sodium alginate evenly to obtain a mixed solution;

[0049] In the fourth step, the mixed solution obtained in the third step is added dropwise to the 3% calcium chloride borate solution in the second step, and soaked for 60 minutes to obtain a natural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com