Method for producing compost by using beer production waste

A waste and composting technology, applied in the field of solid waste recycling, to improve the rhizosphere environment and soil structure, realize recycling, and increase soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

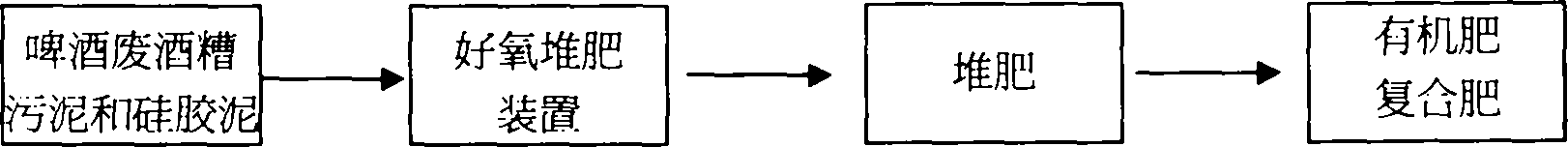

Method used

Image

Examples

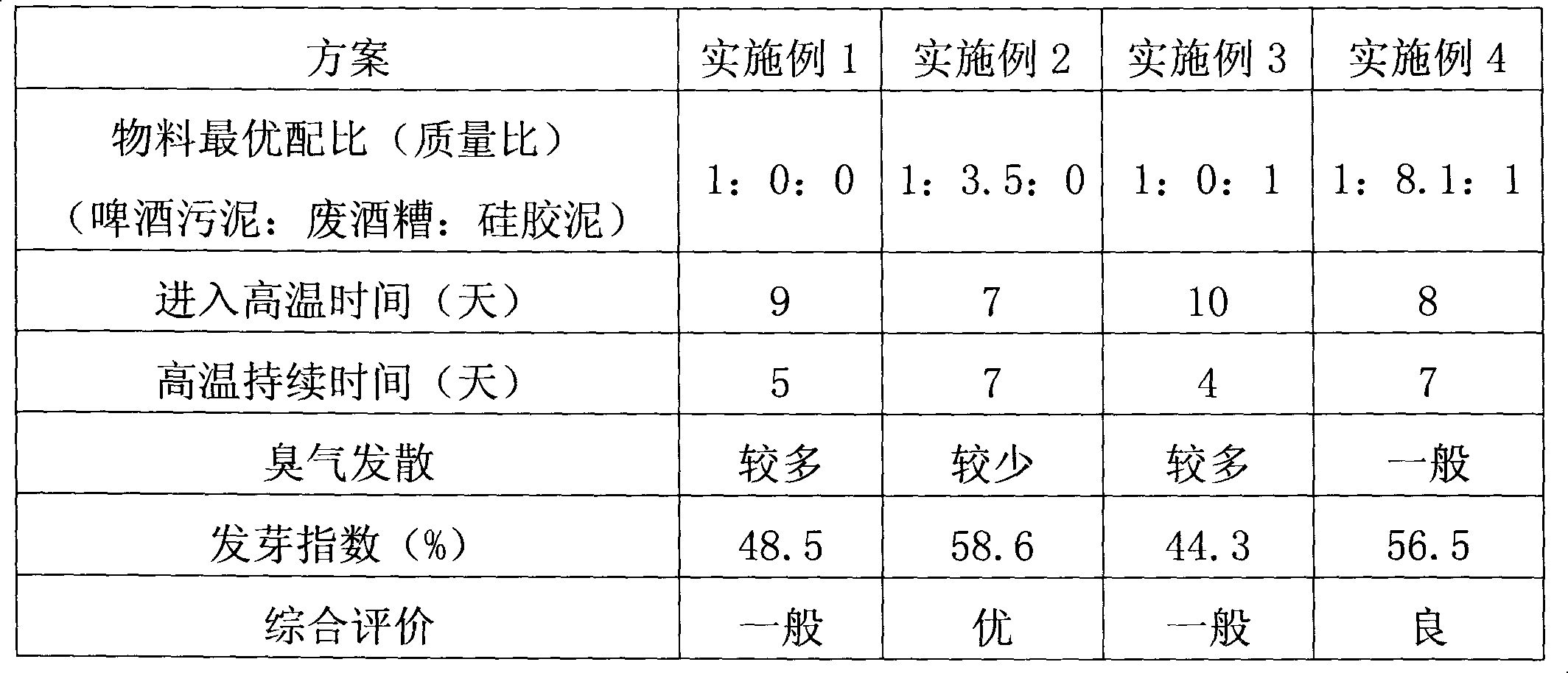

Embodiment 1

[0012] A method for producing compost from beer production waste, the steps comprising:

[0013] 1. Composition of raw materials: 4kg of dewatered sludge in the beer production process was measured to have a pH value of 7, and the total carbon, organic matter, total nitrogen, total phosphorus, total potassium and moisture content were measured, and an appropriate amount of water was added to adjust the moisture content to 59. %;

[0014] 2. Composting: Add the prepared raw materials into the composting reactor, open the air supply device to continuously feed air to ensure that the composting reactor operates in an aerobic state, open the temperature measuring device to monitor the temperature of the composting body in real time, and turn over every 2 days Pile once, and measure the pH value, maturity and oxygen consumption rate of the pile every 3 days. After 13-15 days, the temperature of the pile drops to 28-30°C, and the composting ends;

[0015] The temperature change of ...

Embodiment 2

[0018] A method for producing compost from beer production waste, the steps comprising:

[0019] 1. Composition of raw materials: The waste dewatered sludge and waste distiller's grains discharged from beer production are made into 4 kg of mixed materials according to the weight ratio of 1:3.5, and the pH value is measured to be 7.5, and the total carbon, organic matter, total nitrogen, total phosphorus, and total carbon are measured. Potassium and water content, add appropriate amount of water, adjust the water content to 59%;

[0020] 2. Composting: Add the prepared raw materials into the composting reactor, turn on the air supply device to feed in an appropriate amount of air to ensure that the composting reactor is fermented in an aerobic state, and after the pile is piled up, turn on the temperature measuring device to monitor the pile in real time Temperature: Measure the pH value, maturity and oxygen consumption rate of the heap every 3 days. After 15-17 days, the tempe...

Embodiment 3

[0024] A method for producing compost from beer production waste, the steps comprising:

[0025] 1. Composition of raw materials: The dewatered sludge discharged from beer production and the treated silica gel mud are made into 4kg of mixed materials according to the dry weight ratio of 1:1, and the pH value is measured to be 7.5, and the total carbon, organic matter, total nitrogen, and For total phosphorus, total potassium and moisture content, add appropriate amount of water to adjust the moisture content to 58%;

[0026] The treatment of the silica gel mud refers to: adopting physical evaporation or oxidation to remove the ethanol in the transformed silica gel mud, so as to avoid inhibiting the growth of microorganisms;

[0027] 2. Composting: Add the prepared raw materials into the composting reactor, open the air supply device to continuously feed air to ensure that the composting reactor operates in an aerobic state, and after the compost is piled up, turn on the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com