Corrective natural fracture hydraulic fracturing in-situ stress measurement method

A technology of hydraulic fracturing and stress measurement, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, and measuring fluid pressure, etc. It can solve the problem that the number of primary cracks is large, cannot meet the requirements, and the test workload is heavy And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] We chose a borehole located in Honghe Town, Changle County, Shandong Province for field experiments. The drilling number is HHZK1, the drilling depth is about 400m, the drilling diameter is 94mm, and the lithology revealed is granite. Test Equipment and Literature [33] The test system recorded in is the same, but the key equipment has been upgraded and innovated, such as the data acquisition system and data processing system developed by the project team, and the dual-loop test and the newly developed high-pressure fluid control system. It can record the test section pressure, packer pressure, pressurized flow and backwater flow at the same time, and the test effect is good.

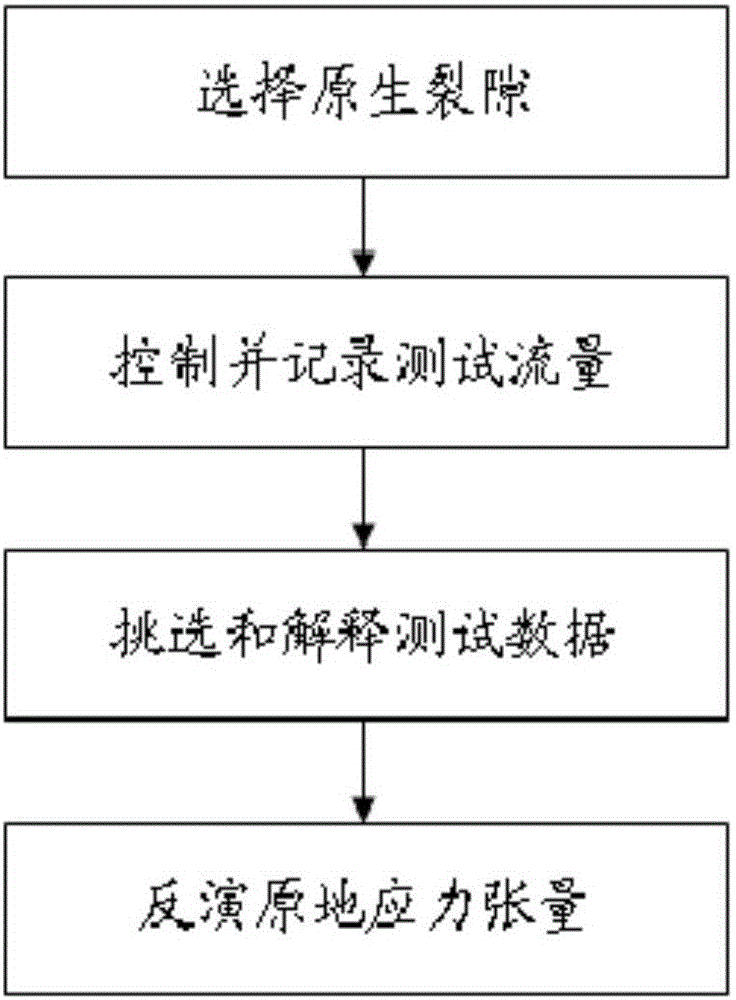

[0057] Specific steps are as follows:

[0058] 1) Select the original crack. The first use of ABI40 ultrasonic downhole TV [31] Accurately locate the fracture surface exposed by the drilling, and the identification accuracy of the fracture surface is about 0.2mm; at the same time, combined wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com