Transmission inspection device and inspection method

A technology of inspection equipment and transmission scanning, which is applied in the direction of material analysis using radiation, material analysis using wave/particle radiation, and measuring devices. It can solve the problems of laborious disassembly and assembly, dispersion, and large parts of inspection equipment to achieve good application. Prospects and economic benefits, simplification of system design, and effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

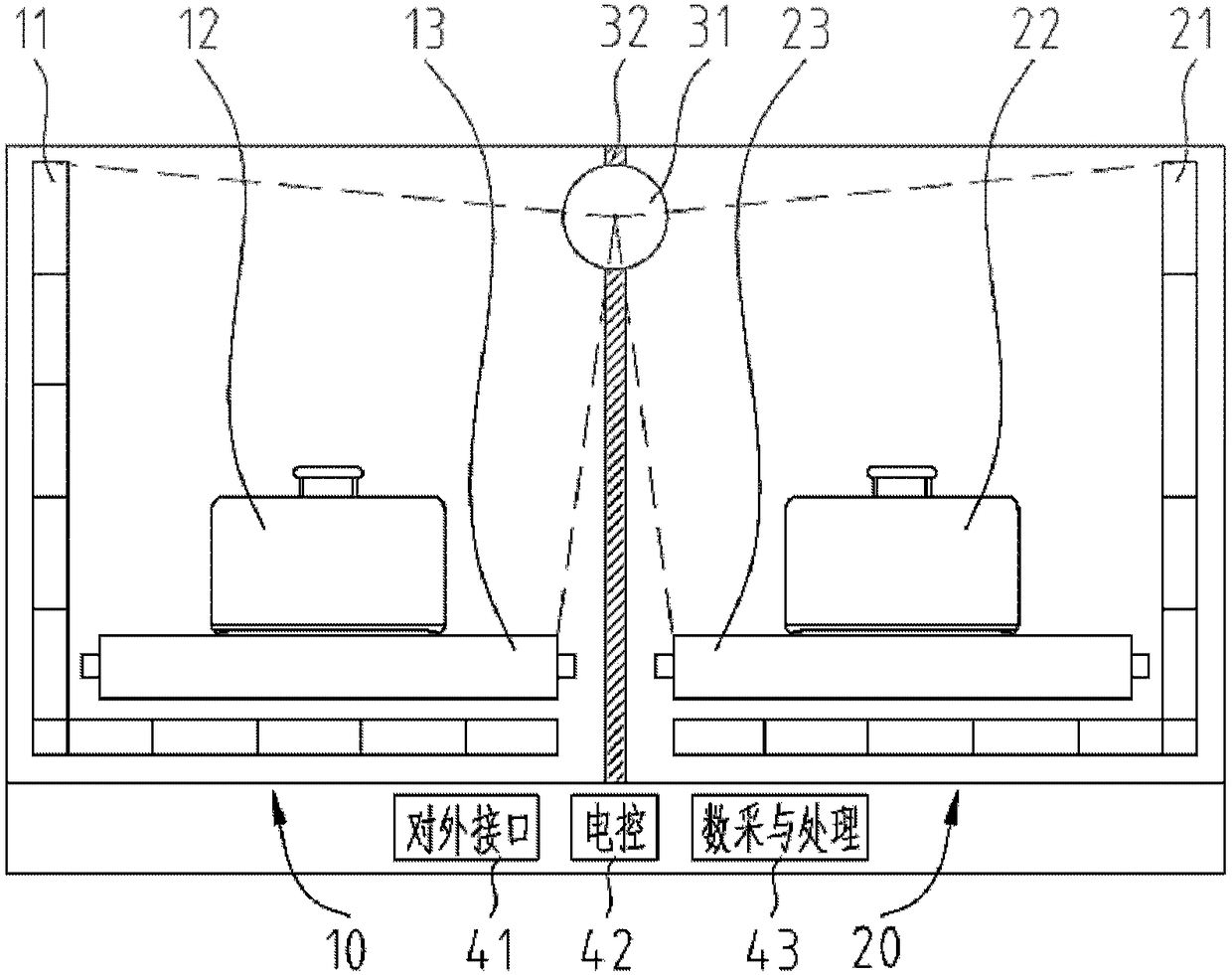

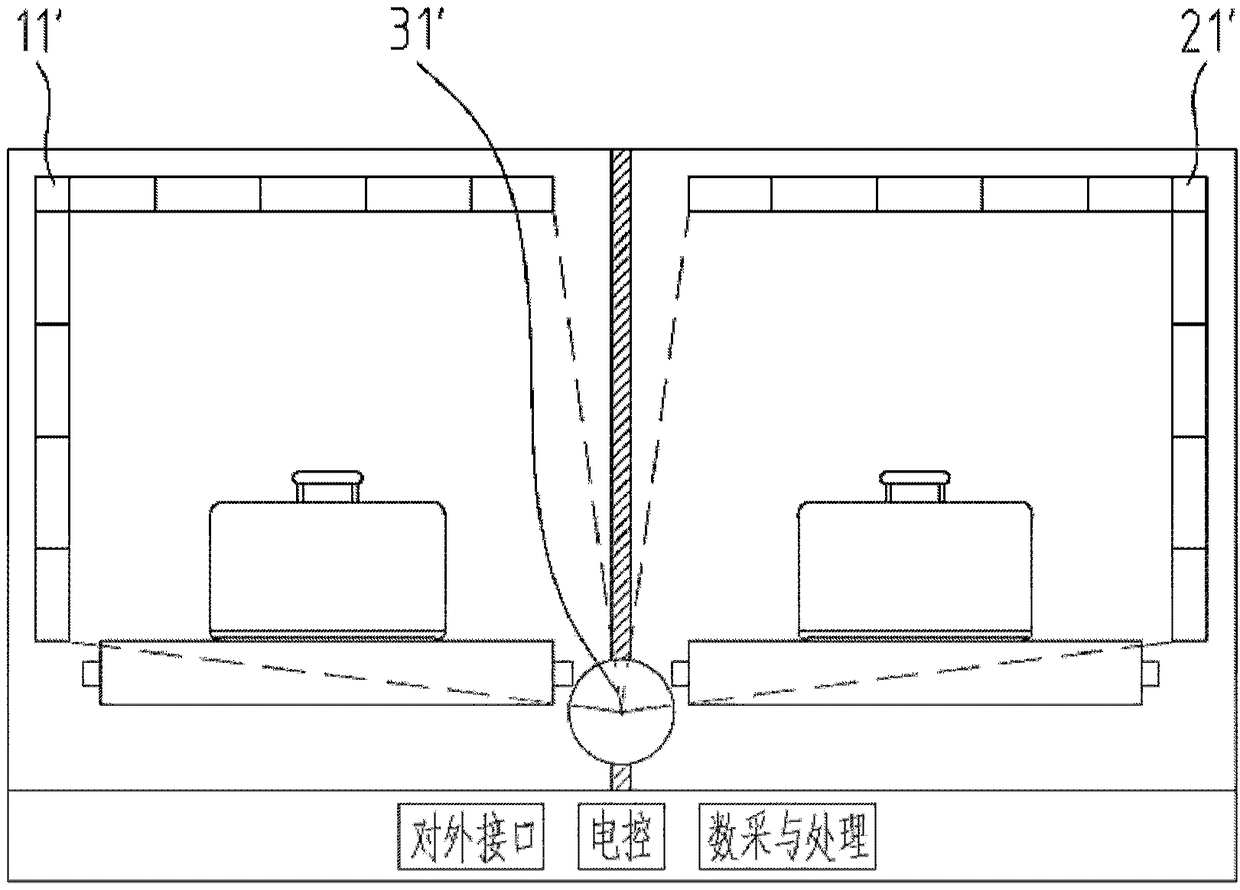

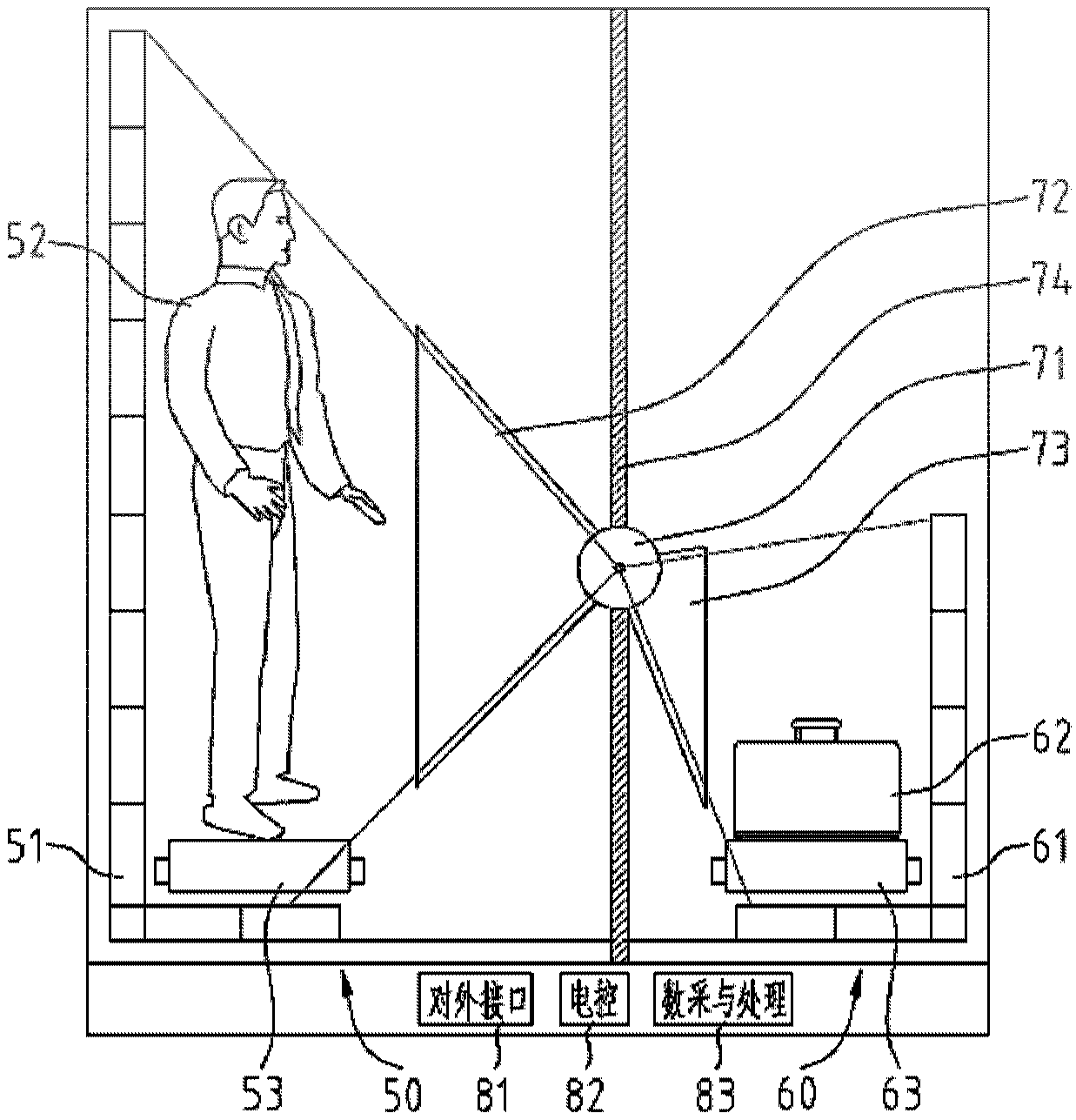

[0031] figure 1 A dual-channel transmission inspection device and a method of use thereof according to an embodiment of the present invention are schematically shown. The dual-channel transmission inspection equipment in this embodiment mainly includes a double-fan beam X-ray machine 31 , a first inspection channel 10 and a second inspection channel 20 . The double-fan beam X-ray machine 31 as the core component is arranged on the top of the device. The double fan beam X-ray machine 31 can generate two X-ray fan beams with corresponding orientations according to system requirements. The first inspection channel 10 includes a first detector 11 and a first conveying device 13 . When the first luggage 12 is checked, the first luggage 12 is placed on the first conveyor 13 . The second inspection channel 20 includes a second detector 21 and a second conveying device 23 . When the second luggage 22 is checked, the second luggage 22 is placed on the second conveyor 23 . The baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com