Depolarization pentagonal prism and manufacturing method thereof

A pentagonal prism and depolarization technology, applied in prisms and other directions, can solve the problems of difficult design and production control, poor repeatability and stability, and poor depolarization effect, so as to reduce the difficulty of design and production control, Good depolarization effect and life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

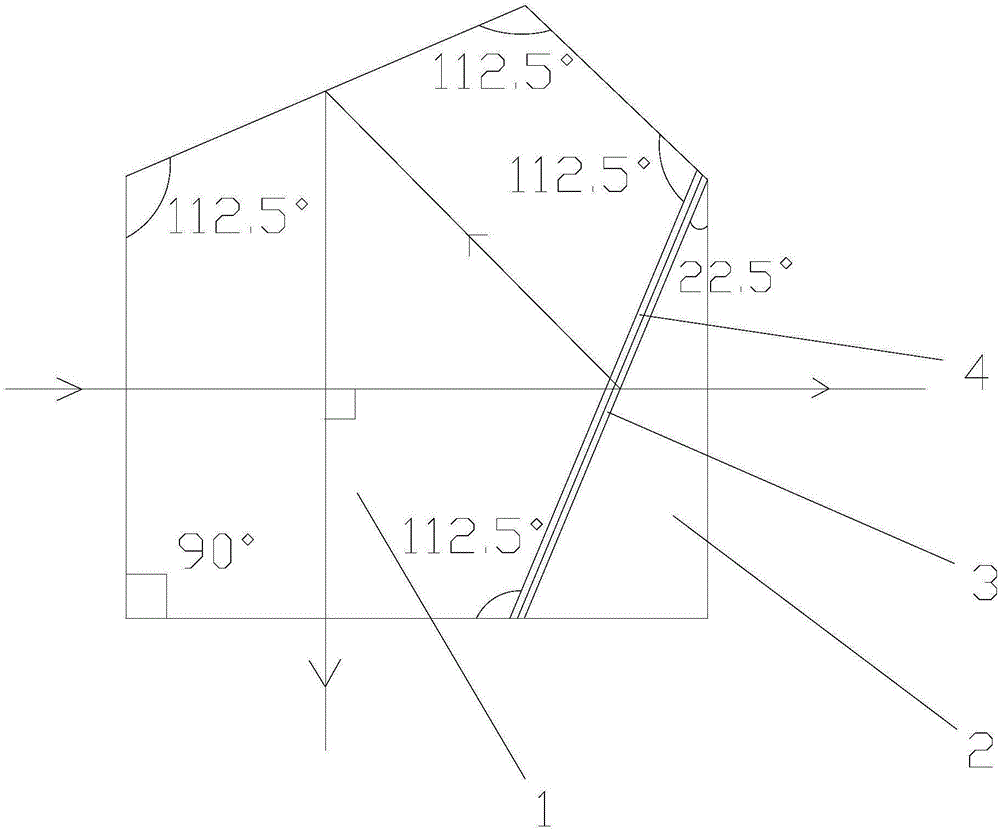

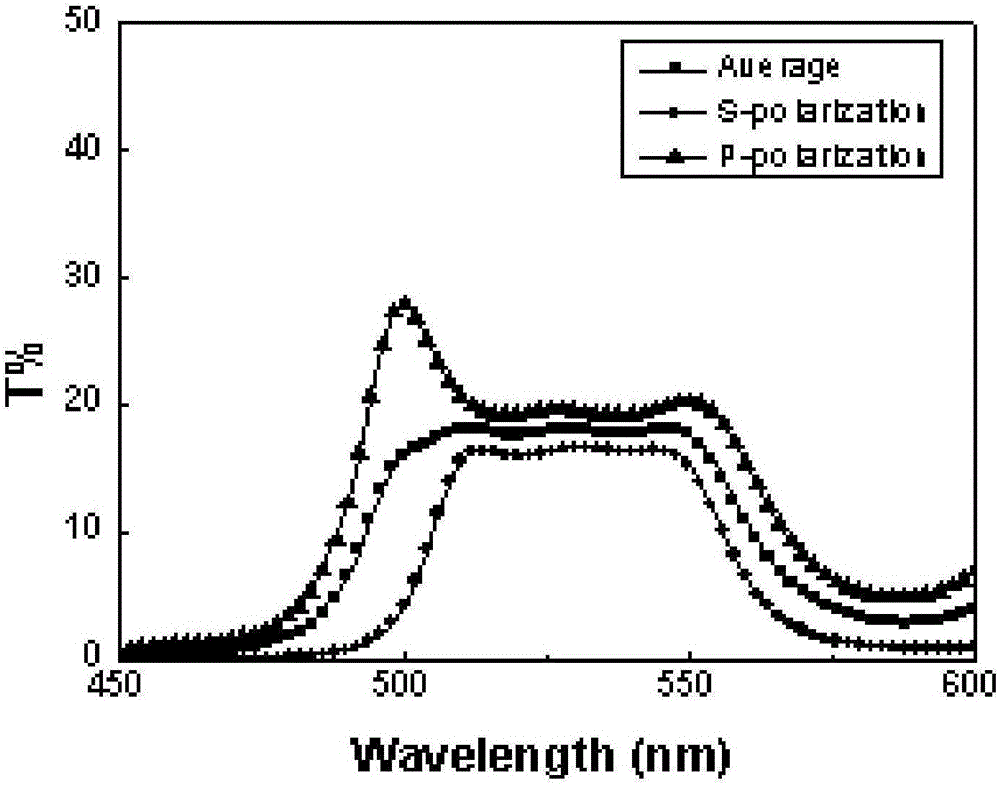

[0033] Such as Figure 1-2 Shown, a kind of depolarization pentagonal prism of the present invention comprises pentagonal prism lens body 1 and angle-wedge sheet 2, and described pentagonal prism lens body 1 is through the longest oblique plane of angle-wedge sheet 2 by an inclined plane adjacent to right-angled surface Edge connection. Described pentagonal prism mirror body 1 and wedge angle sheet 2 adopt same substrate material, also be provided with depolarization medium thin film layer 4 and glue layer 3 between the joint surface of described pentagonal prism mirror body 1 and wedge angle sheet 2, depolarization The dielectric film layer 4 is plated on the pentaprism mirror body 1, and the glue layer 3 is glued between the depolarizing dielectric film layer 4 and the angle wedge sheet 2, and the depolarizing dielectric film layer 4 is made of a high refractive index medium Nb 2 o 5 layer and low-refractive-index dielectric SiO 2 A multi-layer dielectric film structure f...

Embodiment 2

[0041] It differs from Example 1 in that: the number of layers of the depolarizing medium film layer 4 is 29 layers, and each layer is in the order of 1.000H, 1.1338L, and 1.23H according to the order from near to far from the pentagonal prism body 1. , 1.5752L, 1.2721H, 1.1065L, 0.9383H, 0.9955L, 0.8955H, 0.9601L, 0.8379H, 0.8403L, 0.6624H, 0.6573L, 0.587H, 0.7079L, 0.7061H, 0.8478H, 0.82912 L, 0.8033H, 0.5246L, 2.2512H, 0.8212L, 0.836H, 0.7775L, 0.5054H, 0.4454L, 0.6143H, where the value +H represents Nb corresponding to the optical thickness of 1 / 4 wavelength 2 o 5 layer, the value +L represents SiO corresponding to the optical thickness of 1 / 4 wavelength 2 layer, the central wavelength of the depolarizing medium film layer 4 is 590nm.

[0042] In the manufacturing method of the depolarizing pentagonal prism in this embodiment, the coating machine is controlled by a crystal oscillator when the 8th, 22nd, 27-29th layers of the depolarizing dielectric film layer 4 are plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com