A kind of Gansukang capsule and its preparation method

A technology of Gansukang and capsules, which is applied in the field of Gansukang capsules and its preparation, can solve the problems of poor dissolution effect and unresolved taste of Gansukang, and achieve the goal of prolonging residence time, reducing moisture absorption and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

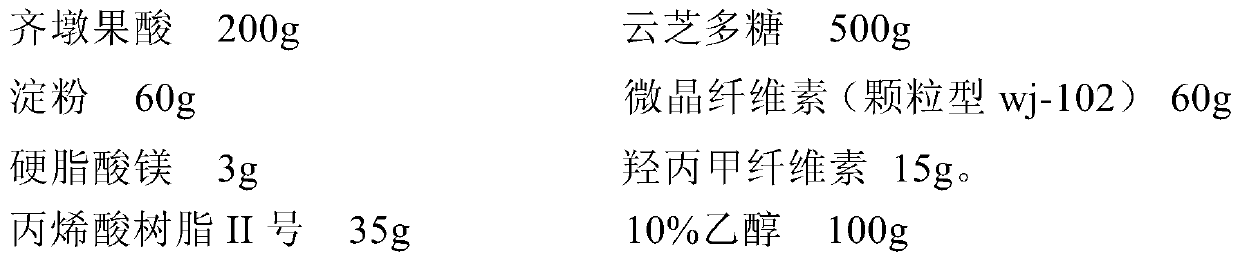

Embodiment 1

[0028]

[0029] Preparation:

[0030] (1) After dissolving oleanolic acid with ethanol, add acrylic resin No. II and stir evenly to obtain a core material.

[0031] (2) Weigh hypromellose, slowly add distilled water under constant stirring to make a 3% water dispersion by mass, and put it in a spray tank for subsequent use;

[0032] (3) Put the core material obtained in step (1) into a fluidized bed, adjust the air inlet temperature to 65°C, the air outlet temperature to 55°C, and the feeding rate to 10ml / min, spray, spray, and pass through 30 meshes after forming microcapsules Sieve, then add polysaccharides from Yunzhi polysaccharide, starch, microcrystalline cellulose, and magnesium stearate, spray and mix evenly, dry at 60°C, sieve with 20-30 meshes for granulation, and obtain Gansukang granules.

[0033] (4) Subpackage: pack the capsule granules prepared in step (2) into capsules to obtain the Gansukang capsules.

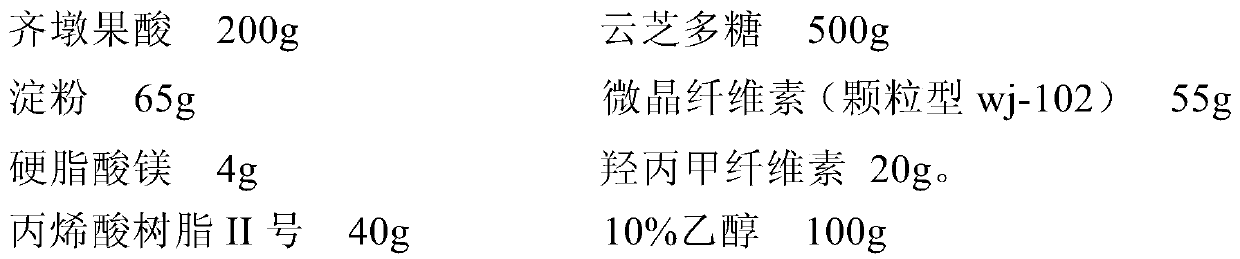

Embodiment 2

[0035]

[0036] Preparation:

[0037] (1) After dissolving oleanolic acid with ethanol, add acrylic resin No. II and stir evenly to obtain a core material.

[0038] (2) Weigh hypromellose, slowly add distilled water under constant stirring to make a 3% water dispersion by mass, and put it in a spray tank for subsequent use;

[0039] (3) Put the core material obtained in step (1) into a fluidized bed, adjust the air inlet temperature to 70°C, the air outlet temperature to 60°C, and the feeding rate to 10ml / min, spray, spray, and pass through 30 meshes after forming microcapsules Sieve, then add polysaccharides from Yunzhi polysaccharide, starch, microcrystalline cellulose, and magnesium stearate, spray and mix evenly, dry at 50°C, sieve with 20-30 meshes for granulation, and obtain Gansukang granules.

[0040] (4) Subpackage: pack the capsule granules prepared in step (2) into capsules to obtain the Gansukang capsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com