Compound reverse-osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and interfacial polymerization, applied in the field of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The embodiment of the present invention discloses a preparation method of a composite reverse osmosis membrane, comprising:

[0028] The support layer arranged on the substrate is coated with polyamine aqueous solution, vesicle solution containing aquaporin and polyacyl chloride organic solution in sequence, and after interfacial polymerization reaction, post-treatment is carried out to obtain a composite reverse osmosis membrane.

[0029] The application provides a method for preparing a composite reverse osmosis membrane, which is coated with an aqueous solution containing polyamines on the support layer, and then coated with a layer of vesicle solution containing aquaporins, and finally mixed with polyacyl chlorides The organic solution undergoes interfacial polymerization to form a desalination layer of vesicles embedded with aquaporin, thereby improving the water flux and desalination rate of the composite reverse osmosis membrane.

[0030] In the process of prepar...

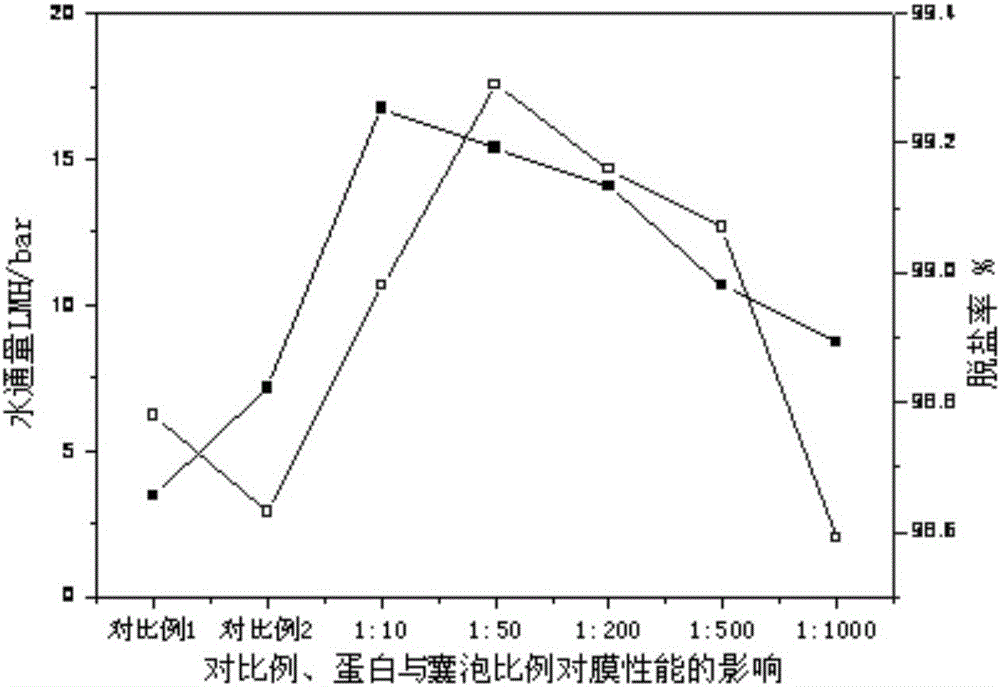

Embodiment 1~5

[0044] Prepare 3.5% m-phenylenediamine aqueous solution and 0.1% sodium dodecylsulfonate, adjust the pH to 12 with NaOH to obtain an aqueous phase solution, coat the solution on the polysulfone porous support layer, and stay for 1 Minutes, then remove excess aqueous solution on the surface of the support layer; the vesicle solution containing AQP is coated on the porous support layer containing amine, the concentration of vesicles is 0.08mg / ml, adjust the molar ratio of protein and vesicles (as shown in Table 1), after purging with nitrogen to remove excess aqueous solution on the surface of the support layer, the cyclohexane solution of 0.08% trimesoyl chloride by mass percent is coated on the above-mentioned polysulfone porous support layer containing m-phenylenediamine and AQP Above, the interfacial polymerization reaction between m-phenylenediamine and trimesoyl chloride occurred for 30 seconds and then stood upright to dry naturally to obtain a reverse osmosis composite me...

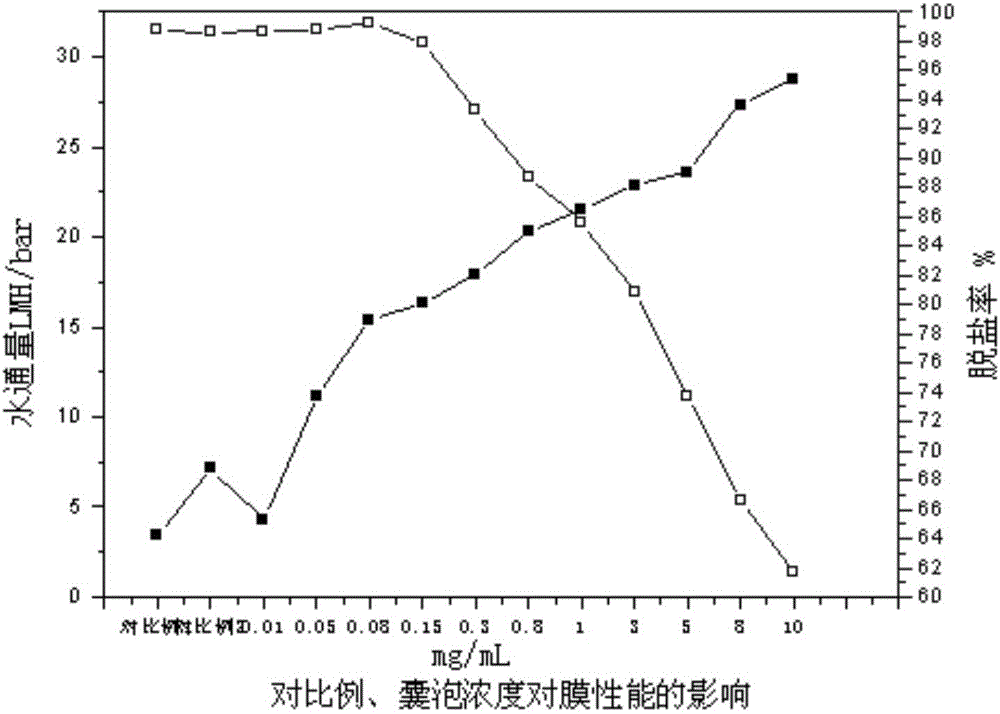

Embodiment 6~16

[0056] Prepare 3.5% m-phenylenediamine aqueous solution and 0.1% sodium dodecylsulfonate, adjust the pH to 12 with NaOH to obtain an aqueous phase solution, coat the solution on the polysulfone porous support layer, and stay for 1 minute , then remove excess aqueous solution on the surface of the support layer, coat the vesicle solution containing AQP on the porous support layer containing amine, wherein the molar ratio of protein to vesicles is 1:50, adjust the concentration of vesicles (as shown in Table 2 shown), after nitrogen purging was used to remove excess aqueous solution on the surface of the support layer, the cyclohexane solution of trimesoyl chloride with a mass percentage of 0.08% was coated on the above-mentioned polysulfone porous support layer containing m-phenylenediamine and AQP , m-phenylenediamine and trimesoyl chloride have an interfacial polymerization reaction for 30 seconds and then stand upright to dry naturally to obtain a reverse osmosis composite me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com