Preparation method of catalyst for methane reforming with carbon dioxide to synthetic gas

A carbon dioxide and catalyst technology, which is applied in the field of preparation of supported nickel-based catalysts, can solve the problems of low metal utilization in carrier channels, accelerate product deep oxidation, increase catalyst cost, etc., improve conversion rate and product selectivity, and avoid further Oxidation, the effect of accelerating the adsorption and desorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

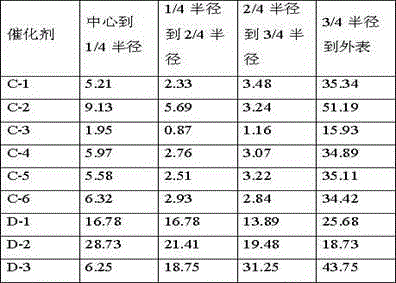

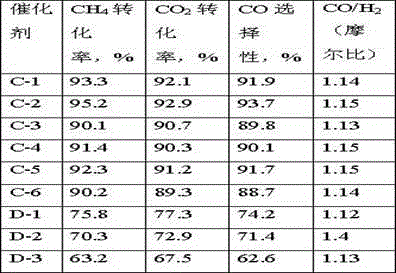

Embodiment 1

[0027] The spent hydrotreating catalyst (MoCo / Al 2 o 3), the oil on the catalyst surface was removed by extraction, dried at 110°C for 8h, and the obtained catalyst was calcined at 450°C for 4h to obtain catalyst precursor A, in which Mo accounted for 9.1wt% by weight of catalyst precursor A in terms of elements, and Co in terms of elements Accounting for catalyst precursor A weight 1.8wt%, Ni accounts for catalyst precursor A weight 3.1wt% in terms of elements, V accounts for catalyst precursor A weight 1.9wt% in terms of elements; 20g catalyst precursor A is mixed in hydrogen-containing Activation in the atmosphere, the volume content of hydrogen in the mixed gas is 80%, the reduction condition is 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; the catalyst precursor A after reduction and activation is mixed with 300mL of sorbitol with a mass concentration of 10% Add the solution into the autoclave, seal it and replace it with hydrogen for 3 times, then adj...

Embodiment 2

[0029] The spent hydrotreating catalyst (MoCo / Al 2 o 3 ), the oil on the catalyst surface was removed by extraction, dried at 110°C for 8h, and the obtained catalyst was calcined at 450°C for 4h to obtain catalyst precursor A, in which Mo accounted for 9.1wt% by weight of catalyst precursor A in terms of elements, and Co in terms of elements Accounting for catalyst precursor A weight 1.8wt%, Ni accounts for catalyst precursor A weight 3.1wt% in terms of elements, V accounts for catalyst precursor A weight 1.9wt% in terms of elements; 20g catalyst precursor A is mixed in hydrogen-containing Activation in the atmosphere, the volume content of hydrogen in the mixed gas is 80%, the reduction condition is 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; the catalyst precursor A after reduction and activation is mixed with 300mL of sorbitol with a mass concentration of 10% Add the solution into the autoclave, seal it and replace it with hydrogen for 3 times, then ad...

Embodiment 3

[0031] The spent hydrotreating catalyst (MoCo / Al 2 o 3 ), the oil on the catalyst surface was removed by extraction, dried at 110°C for 8h, and the obtained catalyst was calcined at 450°C for 4h to obtain catalyst precursor A, in which Mo accounted for 9.1wt% by weight of catalyst precursor A in terms of elements, and Co in terms of elements Accounting for catalyst precursor A weight 1.8wt%, Ni accounts for catalyst precursor A weight 3.1wt% in terms of elements, V accounts for catalyst precursor A weight 1.9wt% in terms of elements; 20g catalyst precursor A is mixed in hydrogen-containing Activation in the atmosphere, the volume content of hydrogen in the mixed gas is 80%, the reduction condition is 450°C, 0.2MPa (absolute pressure), and the reduction time is 4h; the catalyst precursor A after reduction and activation is mixed with 300mL of sorbitol with a mass concentration of 10% Add the solution into the autoclave, seal it and replace it with hydrogen for 3 times, then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com