Energy-saving MBR (membrane bioreactor) sewage treatment system

A sewage treatment system and sewage technology, applied in the field of energy-saving MBR sewage treatment system, can solve problems such as hidden dangers of equipment, unstable flow, frequent changes of frequency conversion control signals, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

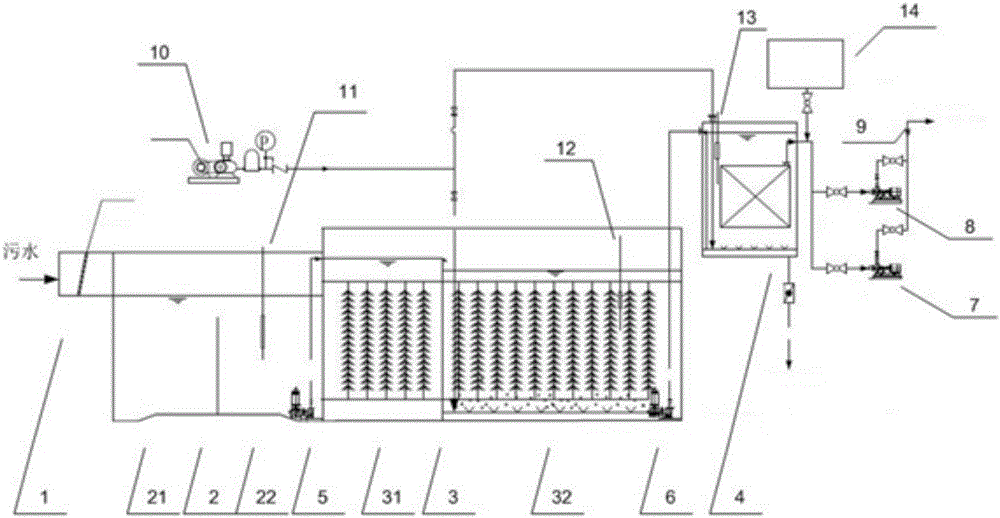

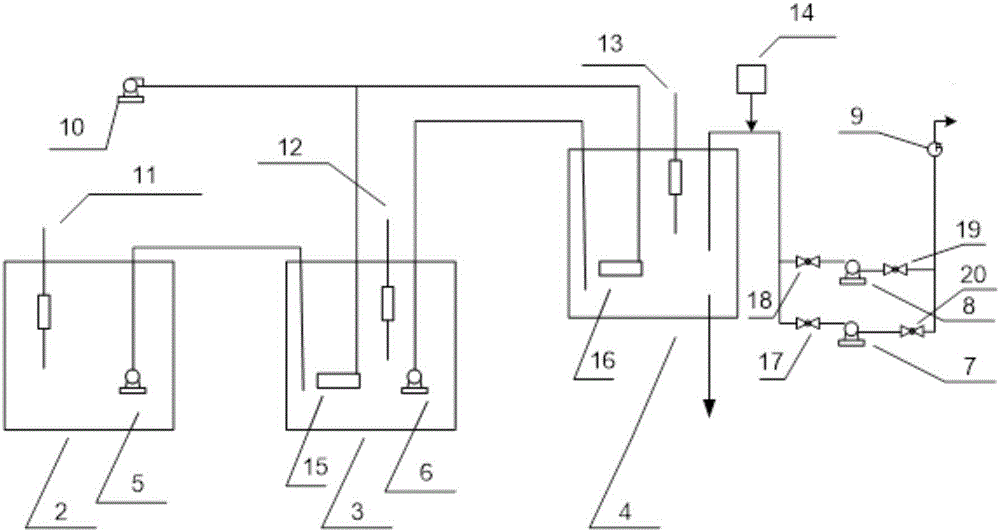

[0060] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0061] Such as figure 1 and figure 2 as shown,

[0062] An energy-saving MBR sewage treatment system, including a grid channel 1, a regulating tank 2, a pretreatment tank 3, an MBR treatment tank 4 with a built-in membrane bioreactor, and a cleaning tank 14 connected in sequence, wherein:

[0063] An aeration device is arranged in the pretreatment tank 3 and the MBR treatment tank 4, and the aeration device shares a fan 10;

[0064] A first liquid level sensor 11 and a first water pump 5 for transferring sewage to the forward treatment tank are provided in the regulating tank 2;

[0065] A second liquid level sensor 12 and a second water pump 6 for transferring sewage to the MBR treatment tank 4 are arranged in the pretreatment tank 3;

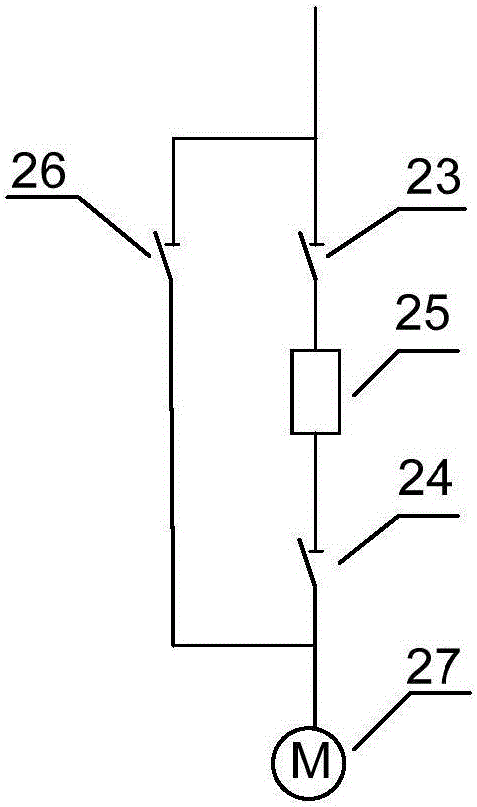

[0066] The third liquid level sensor 13 is provided in the MBR treatment tank 4, and the water outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com