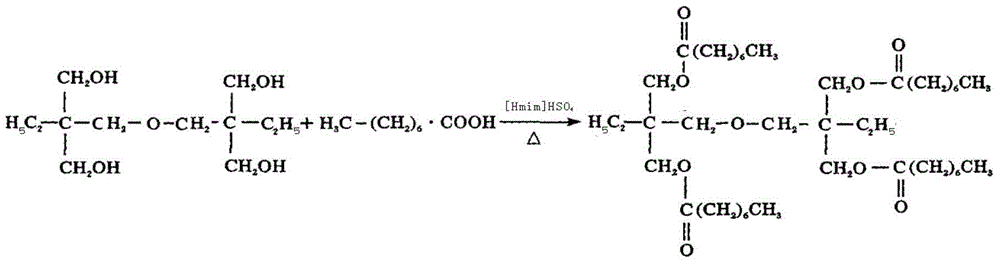

Synthetic method for bis-trimethylolpropane n-octoate used for carbon fiber oil agent

A technology of ditrimethylolpropane and n-octanoate, which is applied in the field of synthesis of ditrimethylolpropane n-octanoate for carbon fiber oil, can solve problems such as unsatisfactory yield, and achieve simple separation and reaction The effect of mild conditions and simplified procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

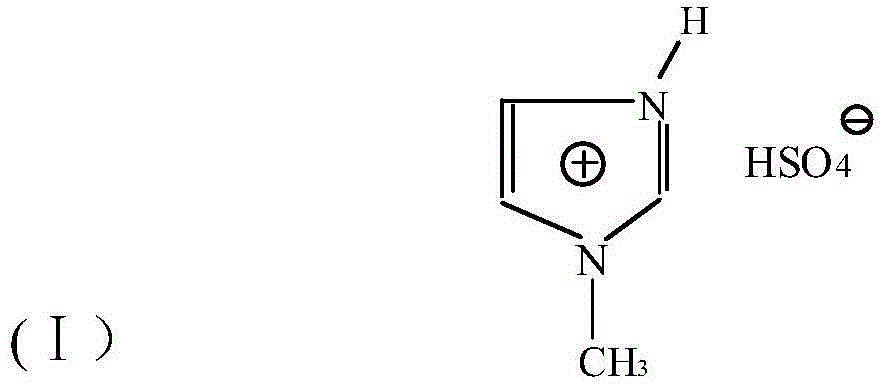

[0033] In a reaction kettle equipped with an electric stirrer, thermometer and condenser, add 55 grams of acidic ionic liquid [Hmim]HSO in sequence 4 , 53 grams of 95wt% ditrimethylolpropane and 124 grams of 98wt% n-octanoic acid. When the temperature is 100°C, the heating rate should be controlled and the temperature should be increased slowly. When the temperature reaches 135°C, keep for 3.5 hours, and the reaction is over.

[0034] The above reaction liquid is cooled to room temperature and separated into layers at rest, the upper layer is the product of ditrimethylolpropane n-octanoate, and the lower layer is an ionic liquid rich in water and containing a trace amount of unreacted octanoic acid raw material. The ditrimethylolpropane n-octanoate in the upper layer is washed with water and dried to obtain a light yellow oily product, and the yield of the esterification reaction product is 97.15%. After the lower layer of ionic liquid is vacuum dehydrated, it is cyclically appli...

Embodiment 2

[0037] Add 56 grams of acidic ionic liquid [Hmim]HSO to the reactor equipped with electric stirrer, thermometer and condenser 4 , 53 grams of 95wt% ditrimethylolpropane and 131 grams of 98wt% n-octanoic acid. Heat up the temperature. When the temperature is 100°C, control the heating rate and slowly increase the temperature. When the temperature reaches 138°C, keep it for 2.5 hours and the reaction ends.

[0038] The above reaction liquid was cooled to room temperature and separated into layers at rest, the upper layer was the product of ditrimethylolpropane n-octanoate, and the lower layer was the ionic liquid rich in water and containing a trace amount of unreacted octanoic acid raw materials. The bistrimethylolpropane n-octanoate in the upper layer was washed with water and dried to obtain a light yellow oily product, and the yield of the esterification reaction product was 97.63%. After the lower layer of ionic liquid is vacuum dehydrated, it is cyclically applied.

[0039] Th...

Embodiment 3

[0041] In a reactor equipped with an electric stirrer, thermometer, and condenser, add 90 grams of acidic ionic liquid [Hmim]HSO in sequence 4 (Recycled application), 53 grams of 95wt% ditrimethylolpropane and 98wt% of n-octanoic acid 128g. Heat up the temperature. When the temperature is 100°C, the temperature rise rate should be controlled and the temperature rise slowly. When the temperature reaches 140°C, keep it for 2 hours, and the reaction ends.

[0042] The above reaction liquid was cooled to room temperature and separated into layers at rest, the upper layer was the product of ditrimethylolpropane n-octanoate, and the lower layer was the ionic liquid rich in water and containing a trace amount of unreacted octanoic acid raw materials. The ditrimethylolpropane n-octanoate in the upper layer was washed with water and dried to obtain a light yellow oily product, and the yield of the esterification reaction product was 97.87%. After the lower layer of ionic liquid is vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com