Solid fuel pyrolysis, gasification, combustion and staged conversion device and method for multi-layer fluidized bed

A multi-layer fluidized bed and solid fuel technology, which is applied to fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve the problems of poor adaptability of solid fuels, graded utilization of semi-coke, and difficulty in semi-coke conversion, etc. problems, to achieve the effect of easy operation and operation, good utilization effect and high active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

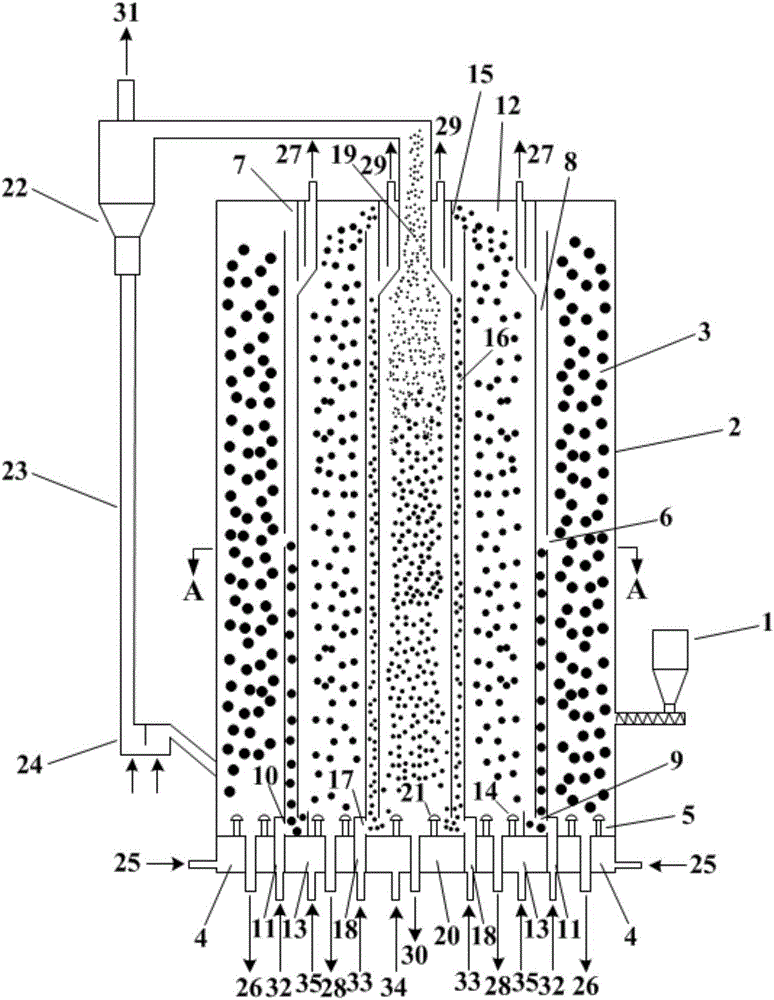

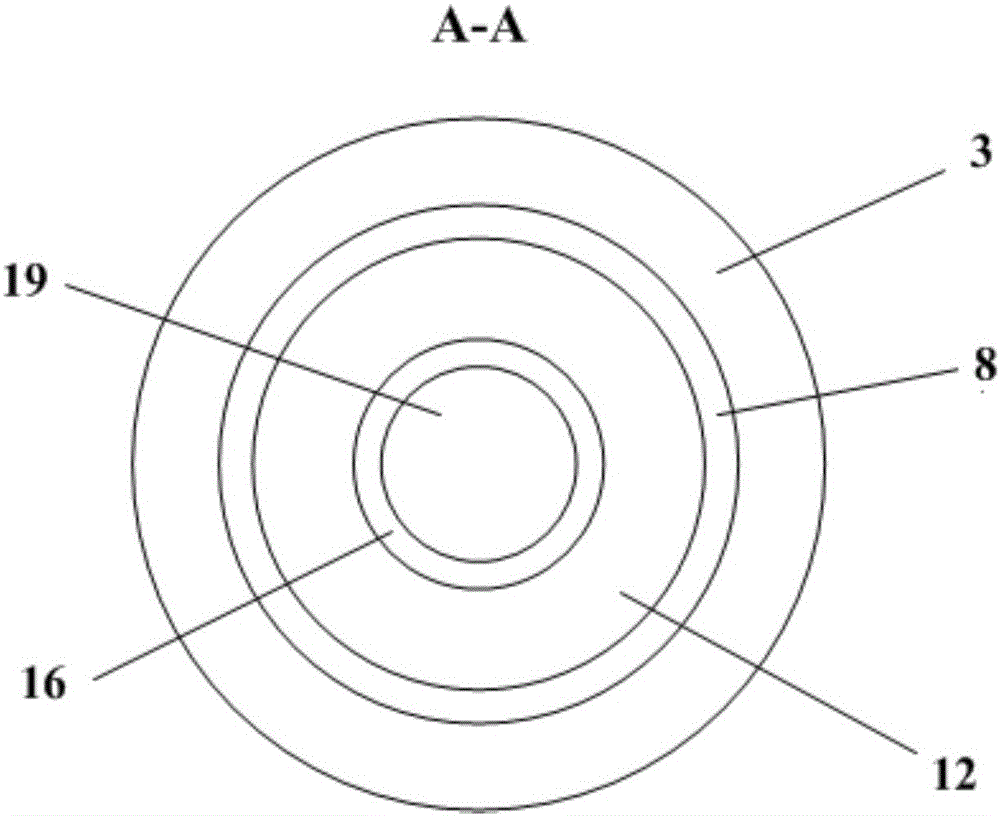

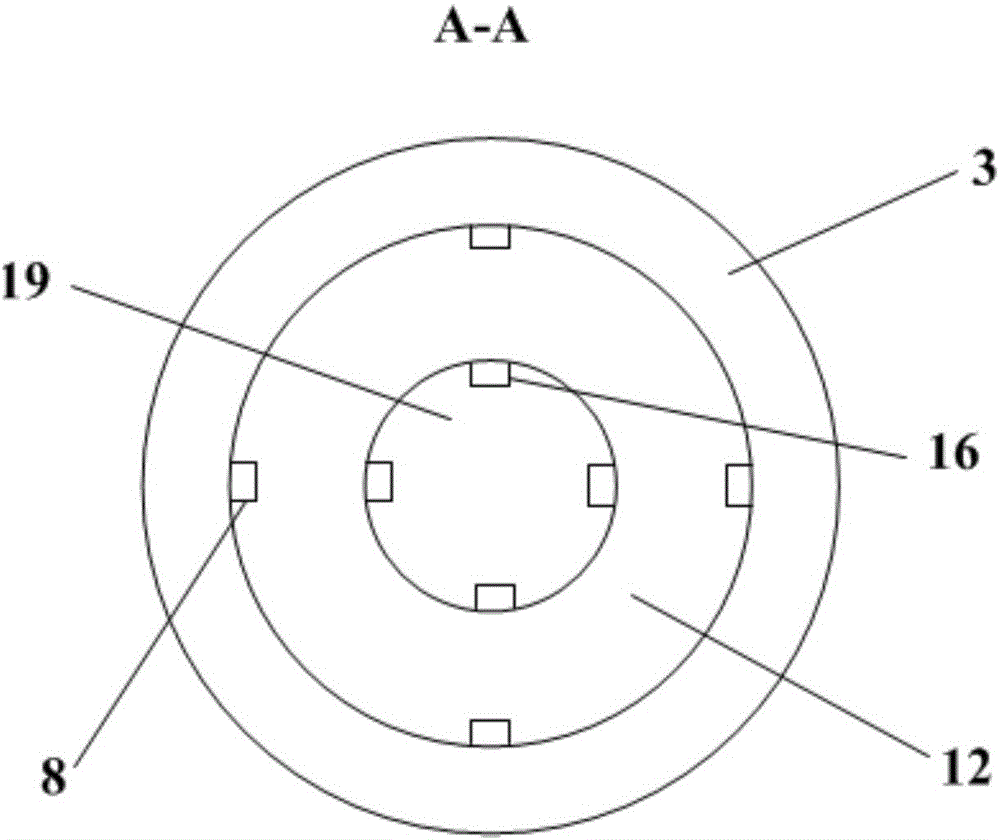

[0023] Such as figure 1 As shown, a multilayer fluidized bed solid fuel pyrolysis gasification combustion graded conversion device includes a solid fuel feeder 1, a multilayer fluidized bed 2, a cyclone separator 22, a standpipe 23, and a feeder 24; The multi-layer fluidized bed 2 described above is divided into a coaxial pyrolysis layer 3, a gasification layer 12, and a combustion layer 19 from the outside to the inside, wherein a communication pyrolysis layer is arranged between the pyrolysis layer 3 and the gasification layer 12. 3. The first dipleg layer 8 of the gasification layer; the middle part of the outer wall of the first dipleg layer 8 near the pyrolysis layer 3 is provided with a semi-coke overflow port 6, and the semi-coke outlet at the bottom of the first dipleg layer 8 A gasification layer return valve 9 is provided at the gasification layer; a second dipleg layer 16 communicating with the gasification layer 12 and the combustion layer 19 is provided between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com